Information injection-pump assembly

ZEXEL

101601-9290

1016019290

Rating:

Cross reference number

ZEXEL

101601-9290

1016019290

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.8

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

50.3

49.3

51.3

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.8+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

9.5

7.7

11.3

Max. variation between cylinders

%

0

-12

12

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.8)

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

50.3

49.3

51.3

Basic

*

Fixing the lever

*

Boost pressure

kPa

14.7

14.7

Boost pressure

mmHg

110

110

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.5

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

74.4

73.4

75.4

Fixing the lever

*

Boost pressure

kPa

14.7

14.7

Boost pressure

mmHg

110

110

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1+0.5

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

83.3

79.3

87.3

Fixing the lever

*

Boost pressure

kPa

14.7

14.7

Boost pressure

mmHg

110

110

Injection quantity adjustment_06

Adjusting point

D

Rack position

R1-0.4

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

43

41

45

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

I

Rack position

14.3+-0.

5

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

81

81

91

Fixing the lever

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

R1-0.4

Boost pressure

kPa

4

4

4

Boost pressure

mmHg

30

30

30

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

R1(11.8)

Boost pressure

kPa

6.7

5.4

8

Boost pressure

mmHg

50

40

60

Timer adjustment

Pump speed

r/min

300

Advance angle

deg.

1

0.5

1.5

Timer adjustment_02

Pump speed

r/min

600-150

Advance angle

deg.

0

0

0

Timer adjustment_03

Pump speed

r/min

1250+-50

Advance angle

deg.

0

0

0

Remarks

Beginning of advance.

Beginning of advance.

Timer adjustment_04

Pump speed

r/min

1400

Advance angle

deg.

1.5

Timer adjustment_05

Pump speed

r/min

1500

Advance angle

deg.

2.5

2

3

Remarks

Finish

Finish

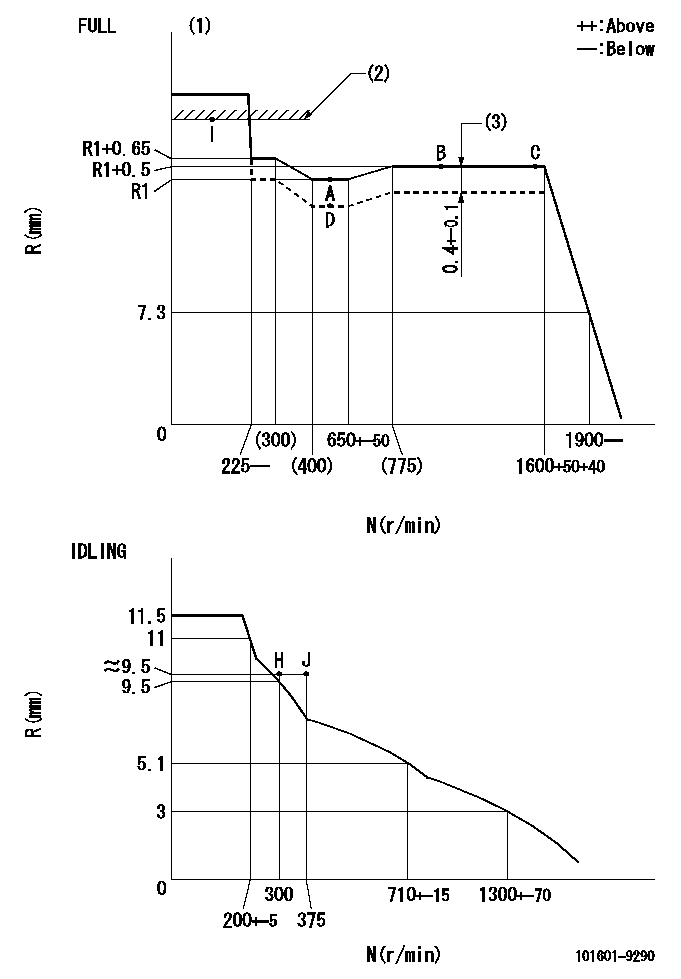

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

(3)Boost compensator stroke

----------

T1=77

----------

----------

T1=77

----------

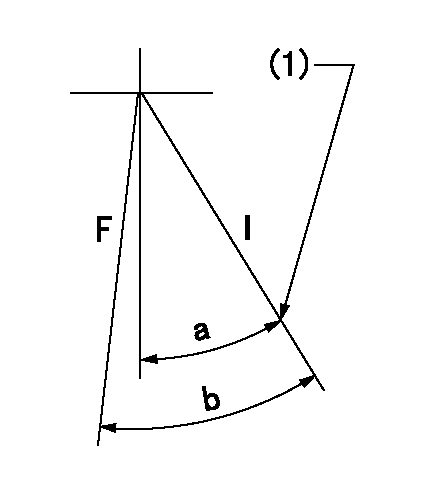

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=36deg+-5deg b=41deg+-3deg

----------

----------

a=36deg+-5deg b=41deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=20deg+-5deg b=40deg+-5deg

----------

----------

a=20deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

1. Loosen bolt (1).2. Loosen bolt (3).3. Push alternator (2) toward the engine to loosen the tension on the two alternator V-belts.4. Remove two alternator V-belts (4) from the alternator drive pulley and fan drive (6).5. Fasten a lifting strap and a hoist to fan drive (6). Remove four bolts (5) and the washers that hold the fan drive to the cylinder head assembly. Remove the fan drive. The weight of the fan drive is approximately 11 kg (25 lb). The following steps are for the installation of the fan drive.6. Be sure the mating surface on the cylinder head assembly and the mating surface on the fan drive support are thoroughly clean.7. Install the fan drive in the reverse order of removal.8. Adjust the tension of the alternator V-belts. See the topic "Alternator And Fan Drive Belts, Inspect/Adjust/Replace" in the 3114 & 3116 ATAAC Diesel Truck Engine Operation & Maintenance Manual, Form No. SEBU6723. Also, refer to the "Belt Tension Chart" in the 3114 & 3116 Diesel Truck Engines Specifications module, Form No. SENR6436.End By:a. install fan drive clutch assemblyDisassemble & Assemble Fan Drive

Start By:a. remove fan drive 1. Remove three bolts (6) and the washers. Access to bolts (6) can be made by rotating the fan pulley.2. Remove fan pulley assembly (2) from fan support (1).3. Remove two bolts (4) and thrust plate (5).4. Remove roller bearing assembly (8) and the bearing retainer from the fan pulley. Remove O-ring seal (7) from the bearing retainer. The following steps are for the assembly of the fan drive group.5. Be sure all parts of the fan drive group are thoroughly clean prior to assembly.6. Check the condition of O-ring seal (7) used in the bearing retainer. Also, check the condition of roller bearing assembly (8). If the components are damaged, use new parts for replacement.7. Install roller bearing assembly (8) in the bearing retainer. Be sure the lip seal in the roller bearing assembly is facing toward the bearing retainer.8. Install O-ring seal (7) in the bearing retainer. Put the bearing retainer and roller bearing assembly, as a unit, in position on pulley (2). Be sure the inner race of the roller bearing assembly in seated against the shoulder on the pulley.9. Install thrust plate (5) and two bolts (4).10. Put pulley assembly (2) in position in fan support (1). Install the three washers and bolts (6) that hold the unit together. Access to the mounting bolt holes can be made by rotating the fan pulley.11. Fill the bearing cavity in the fan drive with 30 g (1 oz) of 2S3230 Bearing Lubricant.End By:a. install fan drive

Start By:a. remove fan drive 1. Remove three bolts (6) and the washers. Access to bolts (6) can be made by rotating the fan pulley.2. Remove fan pulley assembly (2) from fan support (1).3. Remove two bolts (4) and thrust plate (5).4. Remove roller bearing assembly (8) and the bearing retainer from the fan pulley. Remove O-ring seal (7) from the bearing retainer. The following steps are for the assembly of the fan drive group.5. Be sure all parts of the fan drive group are thoroughly clean prior to assembly.6. Check the condition of O-ring seal (7) used in the bearing retainer. Also, check the condition of roller bearing assembly (8). If the components are damaged, use new parts for replacement.7. Install roller bearing assembly (8) in the bearing retainer. Be sure the lip seal in the roller bearing assembly is facing toward the bearing retainer.8. Install O-ring seal (7) in the bearing retainer. Put the bearing retainer and roller bearing assembly, as a unit, in position on pulley (2). Be sure the inner race of the roller bearing assembly in seated against the shoulder on the pulley.9. Install thrust plate (5) and two bolts (4).10. Put pulley assembly (2) in position in fan support (1). Install the three washers and bolts (6) that hold the unit together. Access to the mounting bolt holes can be made by rotating the fan pulley.11. Fill the bearing cavity in the fan drive with 30 g (1 oz) of 2S3230 Bearing Lubricant.End By:a. install fan drive