Information injection-pump assembly

ZEXEL

101601-9280

1016019280

Rating:

Cross reference number

ZEXEL

101601-9280

1016019280

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.3

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

54.7

53.1

56.3

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

8.2

6.4

10

Max. variation between cylinders

%

0

-12

12

Fixing the rack

*

Timer adjustment

Pump speed

r/min

(1230)

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1500

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

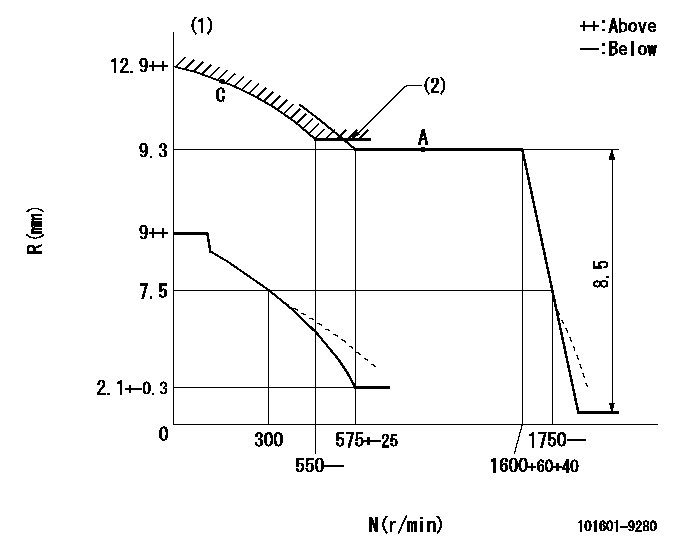

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Excess fuel setting for starting: SXL

----------

DL=7-0.2mm SXL=9.5+0.2mm

----------

----------

DL=7-0.2mm SXL=9.5+0.2mm

----------

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=21deg+-5deg b=26deg+-3deg

----------

----------

a=21deg+-5deg b=26deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=20mm

----------

a=40deg+-5deg b=71deg+-5deg

----------

aa=20mm

----------

a=40deg+-5deg b=71deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

At operating temperature, the engine coolant is hot and under pressure. Steam can cause personal injury. Check the coolant level only after the engine has been stopped and the fill cap is cool enough to touch with your bare hand. Remove the fill cap slowly to relieve pressure in the cooling system. Cooling system conditioner contains alkali. Avoid contact with skin and eyes to prevent personal injury.

1. Drain the coolant from the cooling system into a suitable container for storage or disposal.2. Remove the hose from the water temperature regulator housing. 3. Remove two bolts (1).4. Remove water temperature regulator housing (2) and the gasket from the cylinder head assembly. 5. Remove water temperature regulator (3) from the cylinder head assembly. The following steps are for the installation of the water temperature regulator.

If the water temperature regulator is installed wrong, it will cause the engine to overheat.

6. Put water temperature regulator (3) in position in the cylinder head assembly.7. Install a new gasket and water temperature regulator housing (2).8. Connect the hose to the water temperature regulator housing.9. Fill the cooling system with coolant to the correct level. See the topic "Cooling System" in the 3114 & 3116 ATAAC Diesel Truck Engine Operation & Maintenance Manual, Form No. SEBU6723.