Information injection-pump assembly

ZEXEL

101601-9213

1016019213

Rating:

Cross reference number

ZEXEL

101601-9213

1016019213

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.5

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

73.2

72.2

74.2

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

14.7

14.7

Boost pressure

mmHg

110

110

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.1

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

49.2

48.2

50.2

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

14.7

14.7

Boost pressure

mmHg

110

110

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.7

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

42.6

40.6

44.6

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_04

Adjusting point

D

Rack position

7.8+-0.5

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

9.5

7.7

11.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

57

57

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

8.7

Boost pressure

kPa

4

4

4

Boost pressure

mmHg

30

30

30

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

9.1

Boost pressure

kPa

6.7

5.4

8

Boost pressure

mmHg

50

40

60

Timer adjustment

Pump speed

r/min

300

Advance angle

deg.

1

1

1.5

Timer adjustment_02

Pump speed

r/min

600-150

Advance angle

deg.

0

0

0

Timer adjustment_03

Pump speed

r/min

250+-50

Advance angle

deg.

0

0

0

Timer adjustment_04

Pump speed

r/min

1400

Advance angle

deg.

1.5

Timer adjustment_05

Pump speed

r/min

1500

Advance angle

deg.

2.5

2

3

Remarks

Finish

Finish

Test data Ex:

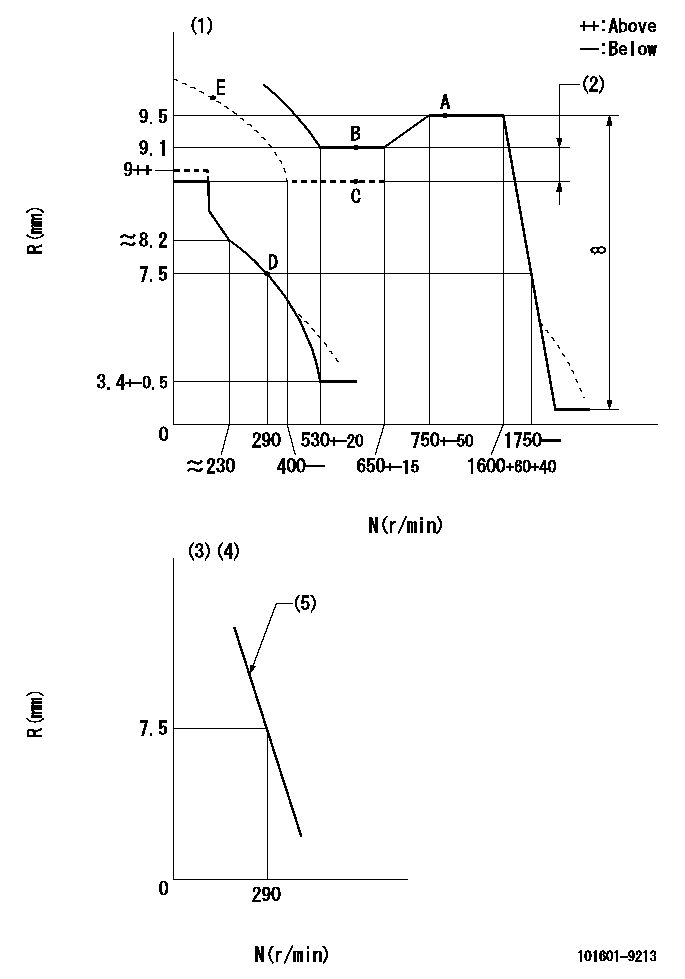

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Boost compensator stroke: BCL

(3)Variable speed specification.

(4)Set idle.

(5)Main spring setting

----------

DL=6.5-0.2mm BCL=0.4+-0.1mm

----------

----------

DL=6.5-0.2mm BCL=0.4+-0.1mm

----------

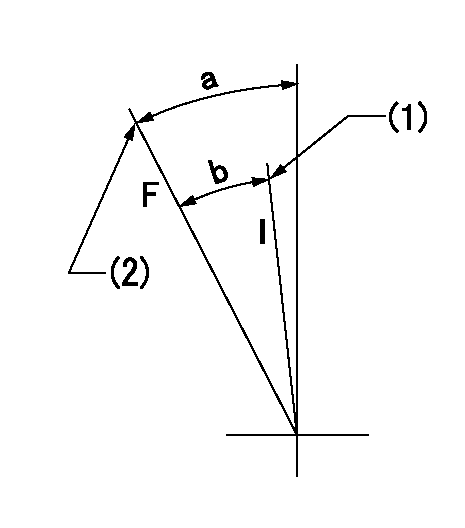

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Stopper bolt setting

----------

----------

a=22deg+-5deg b=(18deg)

----------

----------

a=22deg+-5deg b=(18deg)

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=18.5deg+-5deg b=21deg+-3deg

----------

----------

a=18.5deg+-5deg b=21deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=20mm

----------

a=40deg+-5deg b=71deg+-5deg

----------

aa=20mm

----------

a=40deg+-5deg b=71deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

1. Disconnect wires (1) from the Jake Brake. Remove three bolts (2) and two nuts (3). Remove the Jake Brake. 2. Remove the Jake Brake exhaust bridge assemblies (4). The following steps are for the installation of the Jake Brake.3. Put Jake Brake exhaust bridge assemblies (4) in the same positions shown in Photo C52074P1.4. Position the Jake Brake assembly, and install three bolts (2) and two nuts (3) that hold it. Tighten three bolts (2) to a torque of 55 10 N m (41 7 lb ft). Tighten two nuts (3) to a torque of 80 15 N m (59 11 lb ft).5. Connect wires (1) to the Jake Brake.End By:a. install valve cover assembliesDisassemble & Assemble Jake Brake

Start By:a. remove Jake Brake (An Attachment) 1. Apply finger pressure to control valve cover (6). Remove retaining ring (7). Release finger pressure slowly. Remove control valve cover (6), insert (5), spring (4), spring (3), collar (2) and control valve (1). 2. Remove solenoid (8). Remove three O-ring seals (9) from the solenoid. 3. Remove locknut (11). Back out adjusting screw (10) until the slave piston is fully retracted. 4. Using a suitable size clamp, compress retainer (15) until it is 1mm (.039 in) below the retaining ring groove. Using suitable size snap ring pliers, remove retaining ring (16). Slowly loosen the clamp to release the spring pressure against retainer (15), springs (14) and (13) and slave piston (12). 5. Using suitable snap ring pliers, remove retaining ring (20). Remove retainer (19), spring (18) and master piston assembly (17). The following steps are for the assembly of the Jake Brake.6. Check the condition of the master piston assembly (17). The master piston assembly must be free of score and wear marks.7. Install master piston assembly (17), spring (18), retainer (19) and retaining ring (20).8. Install slave piston (12), springs (13) and (14) and retainer (15). Clamp and compress and slave piston retainer until it is 1 mm (.039 in) below the retaining ring groove. Install retaining ring (16). Release the clamp. Be sure retainer (15) is seated properly.9. Screw adjusting screw (10) in until it makes contact with the slave piston. Install locknut (11) on the screw.

Be sure O-ring seals (9) are seated on solenoid (8). Do not twist or unseat the O-ring seals during installation of the solenoid.

10. Check the condition of the O-ring seals (9) used on solenoid (8). If the seals are worn or damaged, use new parts for replacement. Install three O-ring seals (9) on solenoid valve (8). Install solenoid valve (8), and tighten it to a torque of 7 N m (60 lb in).11. Install control valve (1). Install collar (2) with the longer sleeve area facing up. Install springs (3) and (4) and insert (5). Install control valve cover (6). Install retaining ring (7). Rotate the retaining ring so the retaining ring ears are located away from the slot in the housing. Release finger pressure. For assembly adjustments of

Start By:a. remove Jake Brake (An Attachment) 1. Apply finger pressure to control valve cover (6). Remove retaining ring (7). Release finger pressure slowly. Remove control valve cover (6), insert (5), spring (4), spring (3), collar (2) and control valve (1). 2. Remove solenoid (8). Remove three O-ring seals (9) from the solenoid. 3. Remove locknut (11). Back out adjusting screw (10) until the slave piston is fully retracted. 4. Using a suitable size clamp, compress retainer (15) until it is 1mm (.039 in) below the retaining ring groove. Using suitable size snap ring pliers, remove retaining ring (16). Slowly loosen the clamp to release the spring pressure against retainer (15), springs (14) and (13) and slave piston (12). 5. Using suitable snap ring pliers, remove retaining ring (20). Remove retainer (19), spring (18) and master piston assembly (17). The following steps are for the assembly of the Jake Brake.6. Check the condition of the master piston assembly (17). The master piston assembly must be free of score and wear marks.7. Install master piston assembly (17), spring (18), retainer (19) and retaining ring (20).8. Install slave piston (12), springs (13) and (14) and retainer (15). Clamp and compress and slave piston retainer until it is 1 mm (.039 in) below the retaining ring groove. Install retaining ring (16). Release the clamp. Be sure retainer (15) is seated properly.9. Screw adjusting screw (10) in until it makes contact with the slave piston. Install locknut (11) on the screw.

Be sure O-ring seals (9) are seated on solenoid (8). Do not twist or unseat the O-ring seals during installation of the solenoid.

10. Check the condition of the O-ring seals (9) used on solenoid (8). If the seals are worn or damaged, use new parts for replacement. Install three O-ring seals (9) on solenoid valve (8). Install solenoid valve (8), and tighten it to a torque of 7 N m (60 lb in).11. Install control valve (1). Install collar (2) with the longer sleeve area facing up. Install springs (3) and (4) and insert (5). Install control valve cover (6). Install retaining ring (7). Rotate the retaining ring so the retaining ring ears are located away from the slot in the housing. Release finger pressure. For assembly adjustments of