Information injection-pump assembly

ZEXEL

101601-9020

1016019020

NISSAN-DIESEL

16700Z5502

16700z5502

Rating:

Service parts 101601-9020 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-Z5502

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

ZEXEL

101601-9020

1016019020

NISSAN-DIESEL

16700Z5502

16700z5502

Zexel num

Bosch num

Firm num

Name

101601-9020

16700Z5502 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FD6 * K

FD6 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

2.4

2.35

2.45

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.3

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

60

57.7

62.3

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.3

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

55.7

54.1

57.3

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

10.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

44.5

42.9

46.1

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

8.9+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

8

6.8

9.2

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

450+100-

50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

1.5

1

2

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

3.5

3

4

Timer adjustment_04

Pump speed

r/min

1450

Advance angle

deg.

6

5.5

6.5

Remarks

Finish

Finish

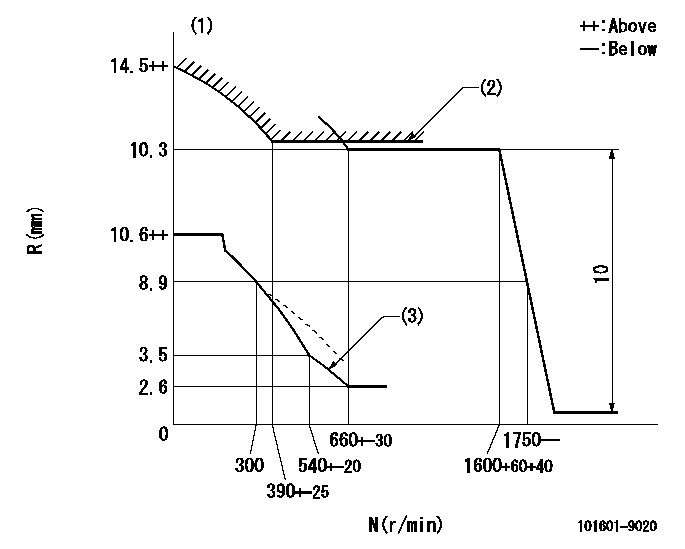

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Excess fuel setting for starting: SXL

(3)Torque control spring setting

----------

DL=8.5-0.2mm SXL=11.6+0.2mm

----------

----------

DL=8.5-0.2mm SXL=11.6+0.2mm

----------

0000000901

F:Full load

I:Idle

----------

----------

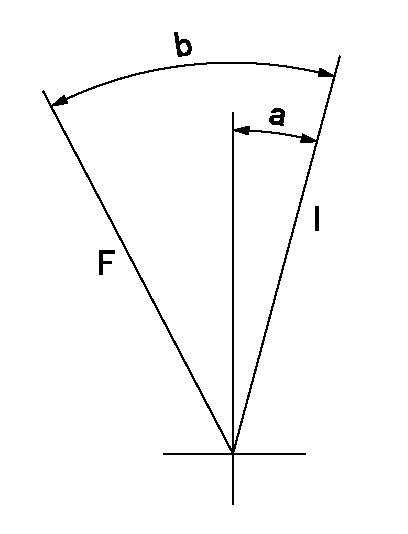

a=6deg+-5deg b=27.5deg+-3deg

----------

----------

a=6deg+-5deg b=27.5deg+-3deg

Information:

A "single" winding (single output) magnetic pickup sensor is recommended for use as a vehicle speed sensor for the 3406B (PEEC III) System. Experience has shown that use of a "dual" winding (dual output) vehicle speed sensor can contribute to electrical noise problems. Vehicle speed buffer negative battery pin must be connected to engine ground, not to cab ground. The vehicle speed circuit consists of the Vehicle Speed Sensor, the Vehicle Speed Buffer and associated wiring. The sensor is a standard magnetic pickup and is supplied by the truck manufacturer. It senses the movement of teeth on the output shaft of the transmission. The buffer (Caterpillar supplied) takes the signal from the sensor, conditions it and sends it to both the ECM and the vehicle speedometer.There are three acceptable options for wiring of the vehicle speed circuit: For all three options, the Vehicle Speed Buffer should be grounded to the same ground point as the ECM. On 3406B (PEEC III) Engines, the ECM ground point is the cylinder head ground stud.Option 1. Use separate sensors for the Vehicle Speed Buffer and the speedometer, with the second sensor supplying the signal to the speedometer. This option completely isolates the two circuits and is preferred by Caterpillar. See Illustration 1.

Illustration 1

Recommended vehicle speed circuit wiring when using two separate sensors.Option 2. Use a single sensor, with the Vehicle Speed Buffer supplying the signal to the speedometer. This option provides good results when correctly wired. Note that this illustration is electrically identical to the schematic in the 3406B (PEEC III) Diesel Truck Engine Electrical Schematic, Form No SENR5152, which is in the complete Service Manual, 3406B (PEEC III) Diesel Truck Engine, Form No. SENR5150, but shows the required grounding for the speedometer more clearly.The 3E0020 buffer provides a second output line for speedometer requiring two signal lines.

Illustration 2

Recommended vehicle speed circuit wiring using a single sensor.Option 3. Use a dual winding sensor, with the second winding supplying the signal to the speedometer. This option is not preferred by Caterpillar, but can provide acceptable results if the sensor is installed correctly.Dual winding sensors may be used in some new OEM installations which have been specifically reviewed by Caterpillar.

Illustration 3

Recommended vehicle speed circuit wiring when using a dual-winding sensor.The Vehicle Speed Buffer has a five-pin connector (J14/P14) with pins to battery negative, battery positive, the ECM and two for the vehicle speedometer.+ Battery (Pin A) supplies battery power to the buffer.- Battery (Pin B) provides battery ground through the cylinder head ground stud.Buffer Output to the ECM (Pin D) supplies a series of 5 volt DC pulses to the ECM. The frequency of the pulses varies directly with the speed of the vehicle.When a single Vehicle Speed Sensor is used, as in Illustration 2, the vehicle speed signal to the speedometer is provided by the buffer.The 3E0020 buffer has two speedometer outputs, one at P14, Pin C and one at P14, Pin E. Output at each one is a series of -8 volt

Illustration 1

Recommended vehicle speed circuit wiring when using two separate sensors.Option 2. Use a single sensor, with the Vehicle Speed Buffer supplying the signal to the speedometer. This option provides good results when correctly wired. Note that this illustration is electrically identical to the schematic in the 3406B (PEEC III) Diesel Truck Engine Electrical Schematic, Form No SENR5152, which is in the complete Service Manual, 3406B (PEEC III) Diesel Truck Engine, Form No. SENR5150, but shows the required grounding for the speedometer more clearly.The 3E0020 buffer provides a second output line for speedometer requiring two signal lines.

Illustration 2

Recommended vehicle speed circuit wiring using a single sensor.Option 3. Use a dual winding sensor, with the second winding supplying the signal to the speedometer. This option is not preferred by Caterpillar, but can provide acceptable results if the sensor is installed correctly.Dual winding sensors may be used in some new OEM installations which have been specifically reviewed by Caterpillar.

Illustration 3

Recommended vehicle speed circuit wiring when using a dual-winding sensor.The Vehicle Speed Buffer has a five-pin connector (J14/P14) with pins to battery negative, battery positive, the ECM and two for the vehicle speedometer.+ Battery (Pin A) supplies battery power to the buffer.- Battery (Pin B) provides battery ground through the cylinder head ground stud.Buffer Output to the ECM (Pin D) supplies a series of 5 volt DC pulses to the ECM. The frequency of the pulses varies directly with the speed of the vehicle.When a single Vehicle Speed Sensor is used, as in Illustration 2, the vehicle speed signal to the speedometer is provided by the buffer.The 3E0020 buffer has two speedometer outputs, one at P14, Pin C and one at P14, Pin E. Output at each one is a series of -8 volt

Have questions with 101601-9020?

Group cross 101601-9020 ZEXEL

Nissan-Diesel

101601-9020

16700Z5502

INJECTION-PUMP ASSEMBLY

FD6

FD6