Information injection-pump assembly

ZEXEL

101601-8863

1016018863

ISUZU

1156017423

1156017423

Rating:

Cross reference number

ZEXEL

101601-8863

1016018863

ISUZU

1156017423

1156017423

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.5

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

73.4

71.8

75

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

8

6.7

9.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.5)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

73.4

72.4

74.4

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

I

Rack position

14+-0.5

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

90

90

98

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1350--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1300

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1400

Advance angle

deg.

2

1.5

2.5

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

4.5

4

5

Remarks

Finish

Finish

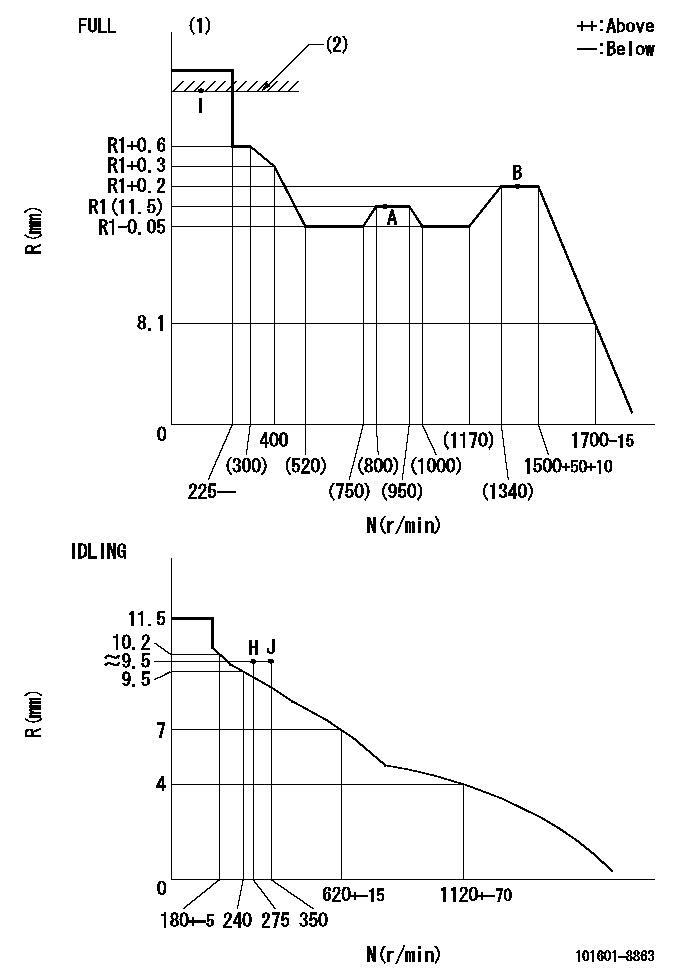

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=C73

----------

----------

T1=C73

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=42deg+-5deg b=35deg+-3deg

----------

aa=35mm

----------

a=42deg+-5deg b=35deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=25deg+-5deg b=40deg+-5deg

----------

----------

a=25deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=13deg

----------

a=(60deg)

----------

aa=13deg

----------

a=(60deg)

Information:

13. Install spring (16), bellcrank (17), and retaining ring (15) on cover assembly (14). 14. Install gasket (24) bellcrank assembly (14) and two bolts (13) on timing advance housing. 15. Install timing advance housing (11) on the timing gear cover. Remove the screwdriver. 16. Check the position (protrusion) of ball detent (25) in tool (B). It should protrude only slightly into the grooved area. During the following steps, tool (B) and the area of installation cannot be seen. The cutaway views are shown for better photo illustration. 17. Install tool (B) with grooved side toward the engine, between the power piston bearing and bellcrank (17) so that ear (26) is in an approximate 9 o'clock position. 18. Apply a slight hand pressure and push tool (B) towards the engine and rotate counterclockwise slowly until ear (27) is in an approximately 9 o'clock position. A slight resistance as the tool starts to seat can be felt.19. Continue to rotate tool (B) counterclockwise until ear (27) is in an approximate 6 o'clock position. 20. Carefully install timing position sensor (6), spring (28), damping washer (29), bracket (8), collar (10) and locknut (9). Do not tighten locknut (9) at this time.21. Connect the wiring harness from the timing position sensor to the wiring harness on the engine. (J2/P2 connector). Be sure that the harness from the PEEC control module is connected to the engine wiring harness. (J7/P7 connector)22. Disconnect the PEEC data link connector (the short pigtail out of the top of the PEEC control module - J4/P4 connector) from the truck wiring harness and connect either tool (C) or tool (D) to the PEEC data link connector (J8 connector).23. Turn power on the PEEC control module. Select "Timing Position Sensor Calibration" from the main menu of tool (C) or (D). See Special Instructions, Form No's. SEHS8742 and/or SEHS8743.

Do not engage the starter, or damage to the engine will be the result.

24. Adjust collar (10) on timing position sensor until the bar graph on tool (C) or (D) is centered and indicate the timing position sensor is calibrated.25. Tighten locknut (9) to 55 7 N m (41 5 lb.ft.).26. Check the timing position calibration reading on tool (C) or (D) to insure that the timing position sensor is still in calibration after tightening the locknut.27. Turn off power to the PEEC control module.28. Disconnect tool (C) or (D) from the PEEC control module. Connect the PEEC data link connector (J1 connector) to the truck harness (P1 connector).29. Remove tool (B) from between the power piston and the bellcrank.30. Use tool (E) to rotate the engine in the clockwise direction to release the pressure on tool (F). Remove tool (F). 31. Lubricate o-ring seal (31) with engine oil and install on timing solenoid (5).32. Install timing solenoid (5) into the timing advance housing. Be sure lever (32) is engaged in the groove of the sleeve. Access port (33) has been provided to visually check the position of lever (32). 33.

Do not engage the starter, or damage to the engine will be the result.

24. Adjust collar (10) on timing position sensor until the bar graph on tool (C) or (D) is centered and indicate the timing position sensor is calibrated.25. Tighten locknut (9) to 55 7 N m (41 5 lb.ft.).26. Check the timing position calibration reading on tool (C) or (D) to insure that the timing position sensor is still in calibration after tightening the locknut.27. Turn off power to the PEEC control module.28. Disconnect tool (C) or (D) from the PEEC control module. Connect the PEEC data link connector (J1 connector) to the truck harness (P1 connector).29. Remove tool (B) from between the power piston and the bellcrank.30. Use tool (E) to rotate the engine in the clockwise direction to release the pressure on tool (F). Remove tool (F). 31. Lubricate o-ring seal (31) with engine oil and install on timing solenoid (5).32. Install timing solenoid (5) into the timing advance housing. Be sure lever (32) is engaged in the groove of the sleeve. Access port (33) has been provided to visually check the position of lever (32). 33.