Information injection-pump assembly

ZEXEL

101601-8620

1016018620

ISUZU

1156014300

1156014300

Rating:

Cross reference number

ZEXEL

101601-8620

1016018620

ISUZU

1156014300

1156014300

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-0220

Overflow valve opening pressure

kPa

147

113

181

Overflow valve opening pressure

kgf/cm2

1.5

1.15

1.85

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.7

3.65

3.75

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.9

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

106.2

104.2

108.2

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

11.2

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

108.1

107.1

109.1

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.6+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

11.5

9.2

13.8

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

-

Pump speed

r/min

150

150

150

Each cylinder's injection qty

mm3/st.

140

140

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

500

Advance angle

deg.

0.3

Timer adjustment_02

Pump speed

r/min

600

Advance angle

deg.

0.8

0.1

0.8

Timer adjustment_03

Pump speed

r/min

700

Advance angle

deg.

0.8

0.3

1.3

Timer adjustment_04

Pump speed

r/min

900

Advance angle

deg.

2

1.5

2.5

Timer adjustment_05

Pump speed

r/min

1150

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

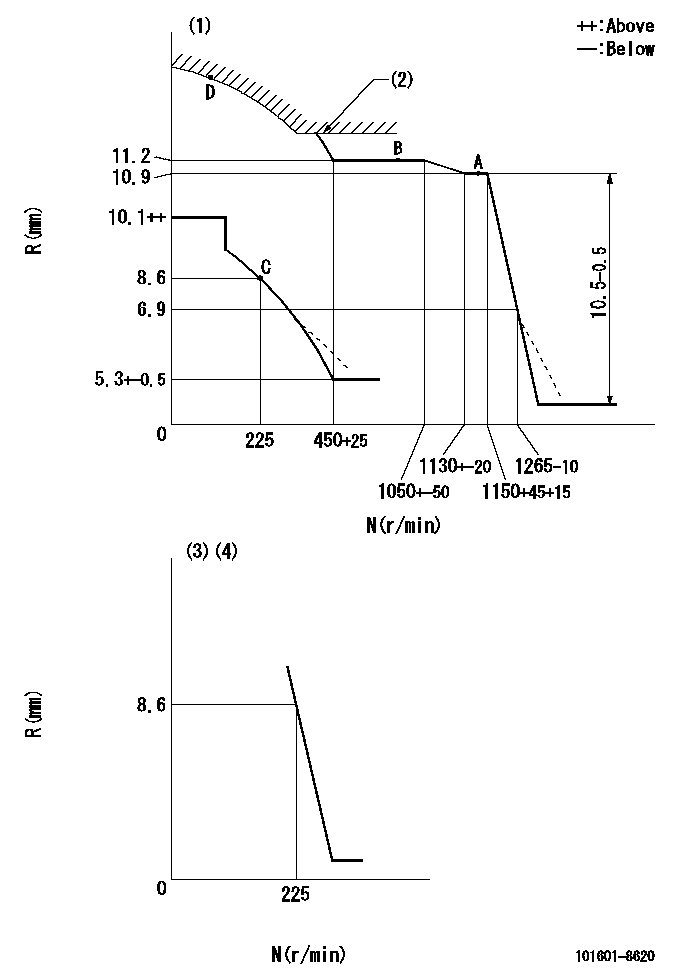

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Excess fuel setting for starting: SXL

(3)Main spring setting

(4)Set the idle spring.

----------

DL=6.5+-0.5mm SXL=12.1+-0.1mm

----------

----------

DL=6.5+-0.5mm SXL=12.1+-0.1mm

----------

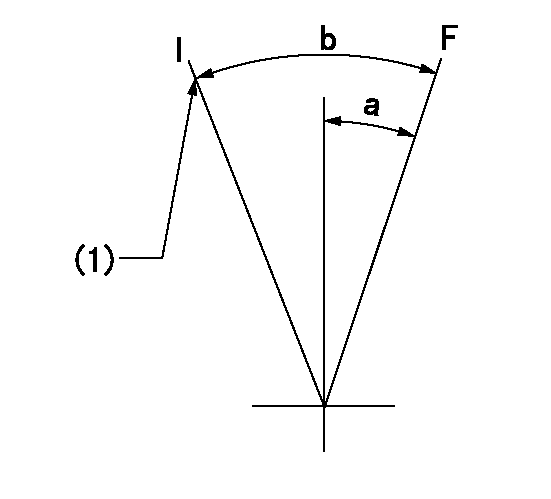

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=3deg+-5deg b=(14deg)+-5deg

----------

----------

a=3deg+-5deg b=(14deg)+-5deg

0000000901

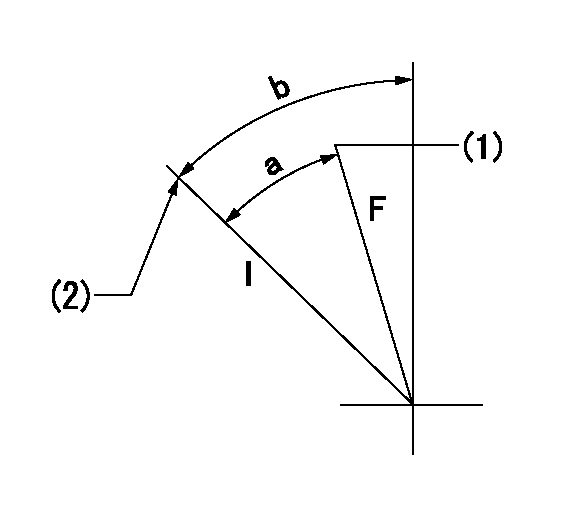

F:Full load

I:Idle

(1)Attach the return spring to the upper hole and adjust.

(2)Stopper bolt setting

----------

----------

a=21deg+-3deg b=30deg+-5deg

----------

----------

a=21deg+-3deg b=30deg+-5deg

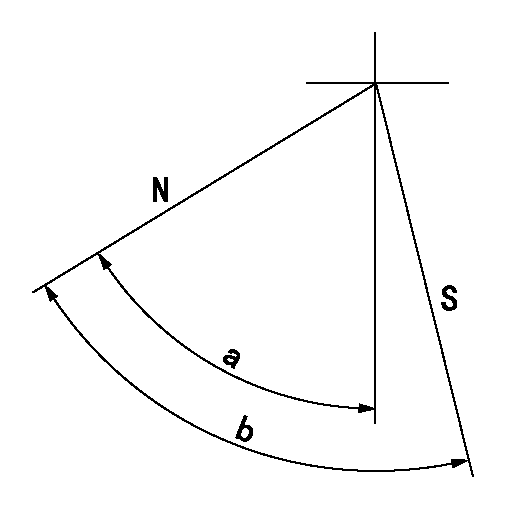

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=65.5deg+-5deg b=71deg+-5deg

----------

----------

a=65.5deg+-5deg b=71deg+-5deg

Information:

Performance Analysis Report (PAR) Chassis Dynamometer Test

Required Equipment For Test:

Optional Equipment:

Refer to the latest PAR instructions, Special Instruction Form No. SEHS8025, for more detailed instructions concerning preparation of the truck, proper use of the dynamometer and use of the Technical Information File microfiche.Use the following procedure for the PAR Chassis Dynamomenter test:1. Check the fuel API if not done in another procedure. Refer to, Special Instruction, Form No. GMGO0977.2. Record data from the Engine Information Plate.3. Install the required measurement instruments on the engine.4. Operate the engine at partial throttle and load to obtain the normal operating temperature, and then operate the engine at full load for two minutes. While operating at full load, check the fuel pressure [approximately 550 kPa (80 psi)]. If the pressure is low, perform Procedure No. 113T (part of Truck Performance Diagnostic Guide, Form No. SEBD0808), before continuing the test.5. Beginning from Top Engine Limit, load the engine to each test rpm, 5 rpm, for at least two minutes for proper stabilization.6. Record engine test information, in sequence if possible, on the record sheets. If repeat runs are required to complete the sheets, be sure temperatures and conditions are as equal as possible.7.

Required Equipment For Test:

Optional Equipment:

Refer to the latest PAR instructions, Special Instruction Form No. SEHS8025, for more detailed instructions concerning preparation of the truck, proper use of the dynamometer and use of the Technical Information File microfiche.Use the following procedure for the PAR Chassis Dynamomenter test:1. Check the fuel API if not done in another procedure. Refer to, Special Instruction, Form No. GMGO0977.2. Record data from the Engine Information Plate.3. Install the required measurement instruments on the engine.4. Operate the engine at partial throttle and load to obtain the normal operating temperature, and then operate the engine at full load for two minutes. While operating at full load, check the fuel pressure [approximately 550 kPa (80 psi)]. If the pressure is low, perform Procedure No. 113T (part of Truck Performance Diagnostic Guide, Form No. SEBD0808), before continuing the test.5. Beginning from Top Engine Limit, load the engine to each test rpm, 5 rpm, for at least two minutes for proper stabilization.6. Record engine test information, in sequence if possible, on the record sheets. If repeat runs are required to complete the sheets, be sure temperatures and conditions are as equal as possible.7.