Information injection-pump assembly

ZEXEL

101601-8052

1016018052

ISUZU

1156013093

1156013093

Rating:

Service parts 101601-8052 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-104-0

12.

Open Pre:MPa(Kqf/cm2)

18.1(185)

15.

NOZZLE SET

Cross reference number

ZEXEL

101601-8052

1016018052

ISUZU

1156013093

1156013093

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.6

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

76.8

75.2

78.4

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

260

260

260

Average injection quantity

mm3/st.

8.1

6.8

9.4

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.6)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

76.8

75.8

77.8

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

I

Rack position

15.3+-0.

5

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

92

92

100

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1350--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1300

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1400

Advance angle

deg.

2

1.5

2.5

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

4.5

4

5

Remarks

Finish

Finish

Test data Ex:

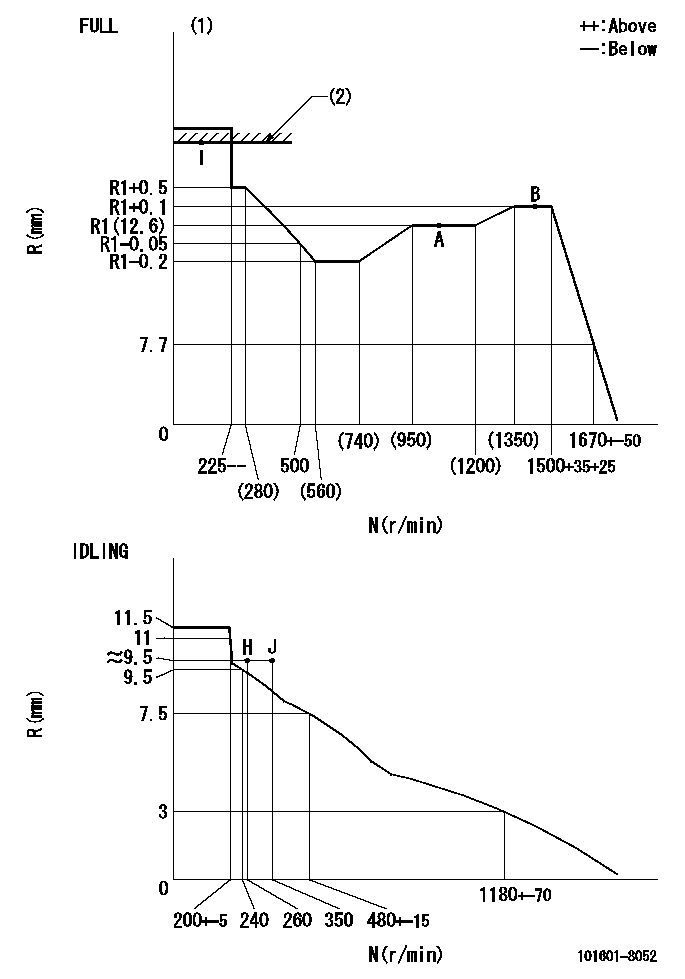

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=C32

----------

----------

T1=C32

----------

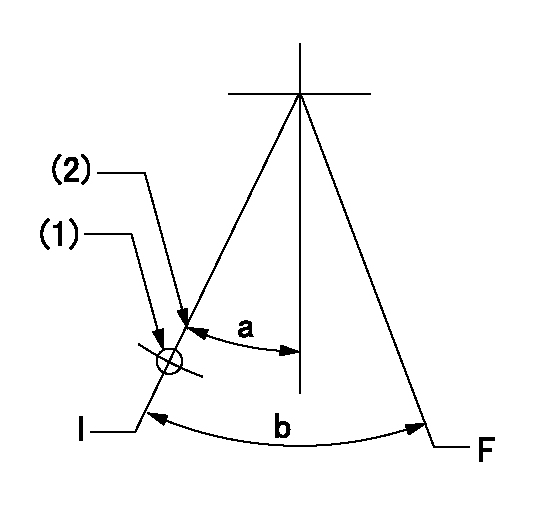

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=45mm

----------

a=21.5deg+-5deg b=(43deg)+-3deg

----------

aa=45mm

----------

a=21.5deg+-5deg b=(43deg)+-3deg

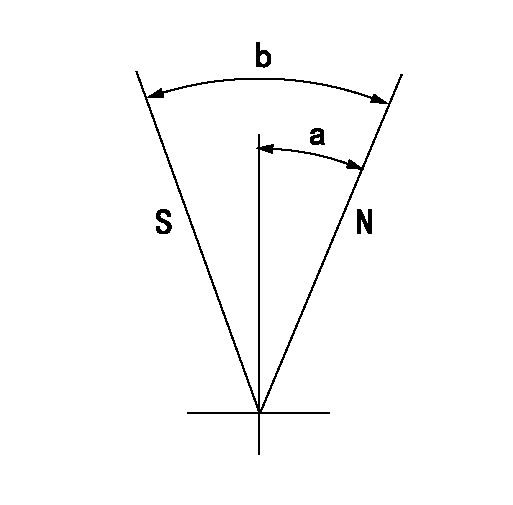

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=25deg+-5deg b=40deg+-5deg

----------

----------

a=25deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(60deg)

----------

aa=12deg

----------

a=(60deg)

Information:

Illustration 15: (A) Injector sleeve. (3) Lower pilot. (36) Pipe or tubing.6. Place new injector sleeve (A) into its bore in the cylinder head. Wipe away any excess retaining compound that is either in or above the injector sleeve.7. Install lower pilot (3) into the injector sleeve. To avoid damage to the guide on the lower pilot (3), use a piece of pipe or tubing (36) with a small hammer to LIGHTLY tap the lower pilot. This will ensure that the new injector sleeve is fully seated in the cylinder head.Remove lower pilot (3).

Illustration 16: (14) Roller expander. (32) Mandrel.8. Place a coating of clean engine oil on 4C-6730 Roller Expander (14). Ensure the rollers are completely covered with oil.9. Pull and hold mandrel (32) out of the roller expander (14) as far as possible. Then completely insert the roller expander into the injector sleeve.10. Place a torque wrench with a 11 mm socket on the hex portion of 4C-6730 Roller Expander mandrel. Turn the torque wrench in a clockwise (CW) direction in order to achieve a torque of 11 N m (100 lb in). If torque stops increasing before 11 N m (100 lb in) the sleeve is not hard enough or the bore is oversized in the head.

To ensure that accurate torque is achieved, a calibrated 4C-6936 Torque Wrench or equivalent is required.

11. When the specified torque is reached, stop turning the roller expander in the clockwise (CW) direction. Now turn the roller expander in the counterclockwise (CCW) direction until it is loose in the injector sleeve.Remove 4C-6730 Roller Expander from the injector sleeve.12. Wipe the roller expander, especially the rollers, to remove any traces of 7M-7456 Bearing Mount or Loctite® 609 that may have built up from the injector sleeve. When usage of 4C-6730 Roller Expander is completed, clean it thoroughly using either 1U-8803 Cleaner Concentrate or 8T-9011 Component Cleaner. After the cleaning, place a generous coat of either 1U-8265 Penetrating Oil or 1U-8809 Rust Preventive on the roller expander. Place it in its storage case.

Illustration 17: (A) Injector sleeve. (13) Driver. (15) Guide bushing. Wage/flaring assembly: (8) Set screw. (9) Bottom swage. (11) Flare tool.13. Install 4C-6591 Bottom Swage (9) in 9U-6856 Flare Tool (11) using 4C-5502 Set Screw (8).14. Slide same guide bushing (15) used previously onto 9U-6856 Flare Tool (11).

Some 9U-6856 Flare Tools have their part number stamped on the turn which fits into the guide bushing. This arrangement interferes with the fit. Before the first tool use, the part number should be filed down as necessary in order to permit fit of the flare tool in the guide bushing.

15. Use 5P-3931 Anti-seize Compound, 6V-4876 Molykote Paste Lubricant, or grease to lubricate the swage/flaring assembly. Place it into the sleeve with the flare tool prying notch facing either opening between the valve springs. This will allow access for removal of the swage/flaring assembly.16. Place 9U-6857 Driver (13) on 9U-6856 Flare Tool (11).17. Use a hammer to drive down the swage/flaring assembly until