Information injection-pump assembly

ZEXEL

101601-7190

1016017190

ISUZU

1156008980

1156008980

Rating:

Service parts 101601-7190 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

5-15300-065-1

12.

Open Pre:MPa(Kqf/cm2)

18.1(185)

13.

NOZZLE-HOLDER

15.

NOZZLE SET

Cross reference number

ZEXEL

101601-7190

1016017190

ISUZU

1156008980

1156008980

Zexel num

Bosch num

Firm num

Name

101601-7190

1156008980 ISUZU

INJECTION-PUMP ASSEMBLY

6BD1 * K

6BD1 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

54.5

52.9

56.1

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

9.4

8.1

10.7

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.6)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

54.5

53.5

55.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(10.6)

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

56.5

54.9

58.1

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1000

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1300

Advance angle

deg.

1.8

1.3

2.3

Timer adjustment_03

Pump speed

r/min

1600

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

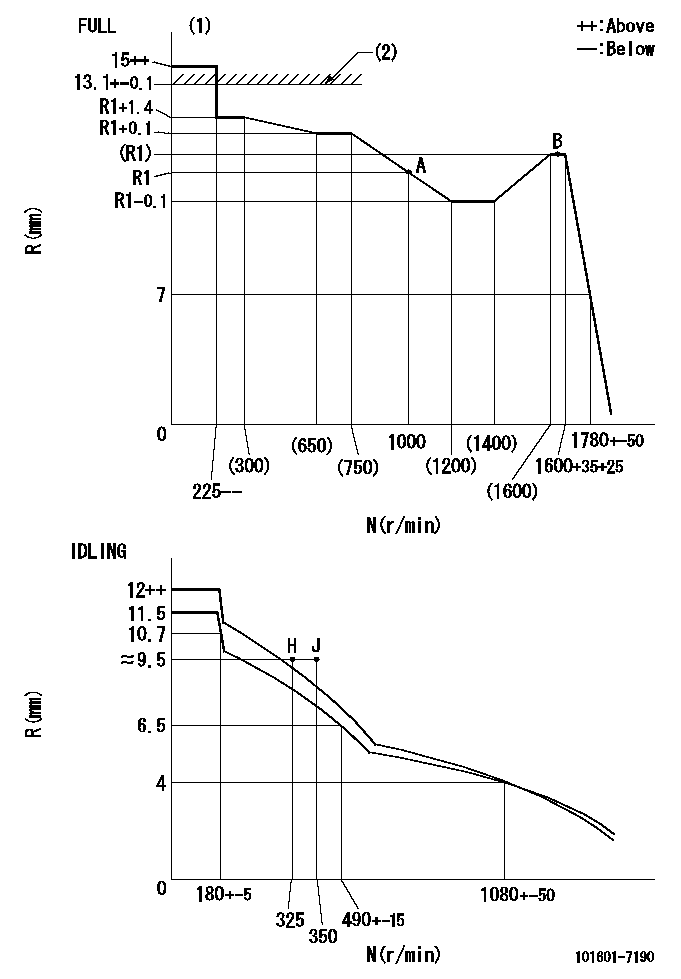

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=10

----------

----------

T1=10

----------

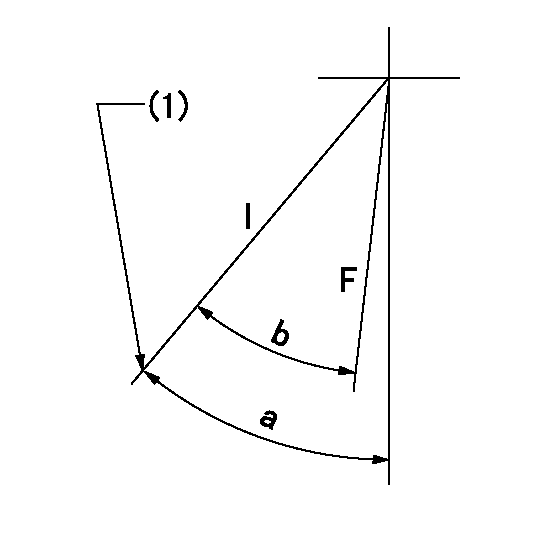

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=40deg+-5deg b=39deg+-3deg

----------

----------

a=40deg+-5deg b=39deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=25deg+-5deg b=40deg+-5deg

----------

----------

a=25deg+-5deg b=40deg+-5deg

Information:

Emissions Warranty

Caterpillar Inc. warrants to the initial owner and subsequent owner of a diesel truck engines (powering on-highway trucks), that such engine is ...1. Designed, built and equipped so as to conform, at the time of sale, with all applicable regulations adopted by the United States Environmental Protection Agency (EPA).2. Free from defects in materials and workmanship in specific emission related parts for a period of 60 months, 100,000 miles (161 000 km) or 3,000 hours of operation, whichever occurs first, after date of delivery to the initial owner.If an emission related part fails during the warranty period, it will be repaired or replaced. Any such part repaired or replaced under warranty is warranted for the remainder of the warranty period.During the term of this warranty, Caterpillar Inc. will provide through a Caterpillar dealer or other establishment authorized by it, repair or replacement of any warranted part at no change to the truck engine owner.In an emergency, repairs may be performed at any service establishment, or by the owner, using any replacement part.Caterpillar Inc. will reimburse the owner for their expenses, including diagnostic charges for such emergency repair. These expenses shall not exceed Caterpillar Inc. suggested retail price for all warranted parts replaced, and labor charges based on Caterpillar Inc. recommended time allowance for the warranty repair and the geographically appropriate hourly labor rate.As a condition of reimbursement, replaced parts and receipted invoices must be presented at a place of business of a Caterpillar dealer or other establishment authorized by Caterpillar Inc.Limitations & Responsibilities

The warranty is subject to the following:Caterpillar Inc. Responsibilities

During the emission warranty period, if a defect in material or workmanship of an emission related part or component is found, Caterpillar Inc. will provide:* New, Remanufactured or repaired parts and/or components, approved pursuant to EPA Regulations, required to correct the defect. Items replaced under this warranty become the property of Caterpillar Inc.* Reasonable and customary labor, during normal working hours, required to make the warranty repair. This includes labor to remove and install the engine, if necessary.Owner Responsibilities

During the emission warranty period, the owner is responsible for:* Premium or overtime labor costs, unless essential to prevent loss to perishable goods.* Costs to investigate complaints which are not caused by a defect in Caterpillar Inc. material or workmanship.* Providing timely notice of a warrantable failure and promptly making the product available for repair.Limitations

Caterpillar Inc. is not responsible for resultant damages to an emission related part or component resulting from:* Any application or installation Caterpillar Inc. deems improper.* Attachments, accessory items or parts not sold nor approved by Caterpillar Inc.* Improper truck engine maintenance, repair or abuse.* Owner's unreasonable delay in making the product available after being notified of a potential product problem.This warranty is in addition to Caterpillar Inc. standard warranty, applicable to the truck engine product involved.Remedies under this warranty are limited to the provision of material and services as specified herein. Caterpillar Inc. is not responsible for incidental or consequential damages.

Caterpillar Inc. warrants to the initial owner and subsequent owner of a diesel truck engines (powering on-highway trucks), that such engine is ...1. Designed, built and equipped so as to conform, at the time of sale, with all applicable regulations adopted by the United States Environmental Protection Agency (EPA).2. Free from defects in materials and workmanship in specific emission related parts for a period of 60 months, 100,000 miles (161 000 km) or 3,000 hours of operation, whichever occurs first, after date of delivery to the initial owner.If an emission related part fails during the warranty period, it will be repaired or replaced. Any such part repaired or replaced under warranty is warranted for the remainder of the warranty period.During the term of this warranty, Caterpillar Inc. will provide through a Caterpillar dealer or other establishment authorized by it, repair or replacement of any warranted part at no change to the truck engine owner.In an emergency, repairs may be performed at any service establishment, or by the owner, using any replacement part.Caterpillar Inc. will reimburse the owner for their expenses, including diagnostic charges for such emergency repair. These expenses shall not exceed Caterpillar Inc. suggested retail price for all warranted parts replaced, and labor charges based on Caterpillar Inc. recommended time allowance for the warranty repair and the geographically appropriate hourly labor rate.As a condition of reimbursement, replaced parts and receipted invoices must be presented at a place of business of a Caterpillar dealer or other establishment authorized by Caterpillar Inc.Limitations & Responsibilities

The warranty is subject to the following:Caterpillar Inc. Responsibilities

During the emission warranty period, if a defect in material or workmanship of an emission related part or component is found, Caterpillar Inc. will provide:* New, Remanufactured or repaired parts and/or components, approved pursuant to EPA Regulations, required to correct the defect. Items replaced under this warranty become the property of Caterpillar Inc.* Reasonable and customary labor, during normal working hours, required to make the warranty repair. This includes labor to remove and install the engine, if necessary.Owner Responsibilities

During the emission warranty period, the owner is responsible for:* Premium or overtime labor costs, unless essential to prevent loss to perishable goods.* Costs to investigate complaints which are not caused by a defect in Caterpillar Inc. material or workmanship.* Providing timely notice of a warrantable failure and promptly making the product available for repair.Limitations

Caterpillar Inc. is not responsible for resultant damages to an emission related part or component resulting from:* Any application or installation Caterpillar Inc. deems improper.* Attachments, accessory items or parts not sold nor approved by Caterpillar Inc.* Improper truck engine maintenance, repair or abuse.* Owner's unreasonable delay in making the product available after being notified of a potential product problem.This warranty is in addition to Caterpillar Inc. standard warranty, applicable to the truck engine product involved.Remedies under this warranty are limited to the provision of material and services as specified herein. Caterpillar Inc. is not responsible for incidental or consequential damages.

Have questions with 101601-7190?

Group cross 101601-7190 ZEXEL

Isuzu

101601-7190

1156008980

INJECTION-PUMP ASSEMBLY

6BD1

6BD1