Information injection-pump assembly

BOSCH

9 400 610 081

9400610081

ZEXEL

101601-6781

1016016781

MITSUBISHI

ME036846

me036846

Rating:

Service parts 101601-6781 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME036780

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 610 081

9400610081

ZEXEL

101601-6781

1016016781

MITSUBISHI

ME036846

me036846

Zexel num

Bosch num

Firm num

Name

101601-6781

9 400 610 081

ME036846 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D14 K

6D14 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-3720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.5

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

61.5

59.7

63.3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

9.7+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

10.5

9

12

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.5)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

61.5

60.5

62.5

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(11.5)

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

65.8

63.1

68.5

Difference in delivery

mm3/st.

5.4

5.4

5.4

Fixing the lever

*

Timer adjustment

Pump speed

r/min

850+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

2.6

2.1

3.1

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

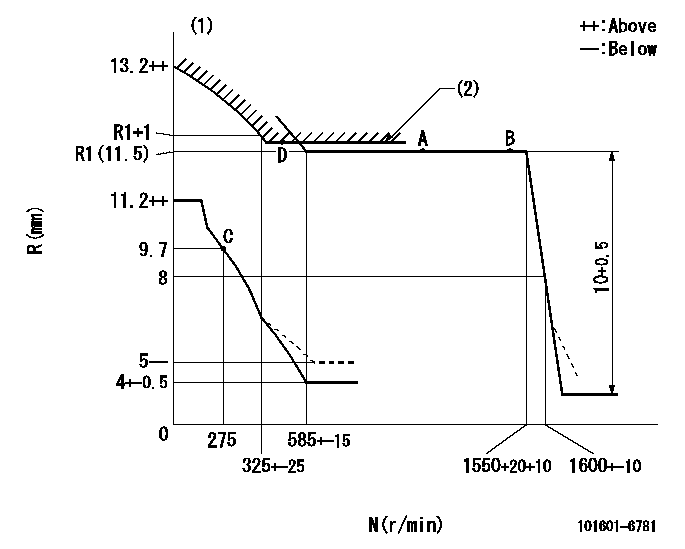

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Excess fuel setting for starting: SXL

----------

DL=6.5-0.2mm SXL=R1+1+0.8mm

----------

----------

DL=6.5-0.2mm SXL=R1+1+0.8mm

----------

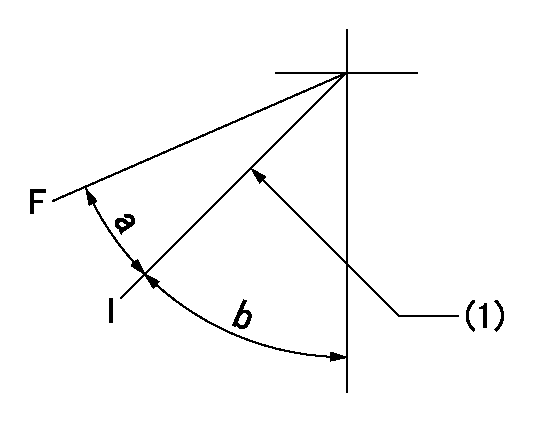

Speed control lever angle

F:Full speed

----------

----------

a=13deg+-5deg

----------

----------

a=13deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=27deg+-5deg b=57deg+-5deg

----------

----------

a=27deg+-5deg b=57deg+-5deg

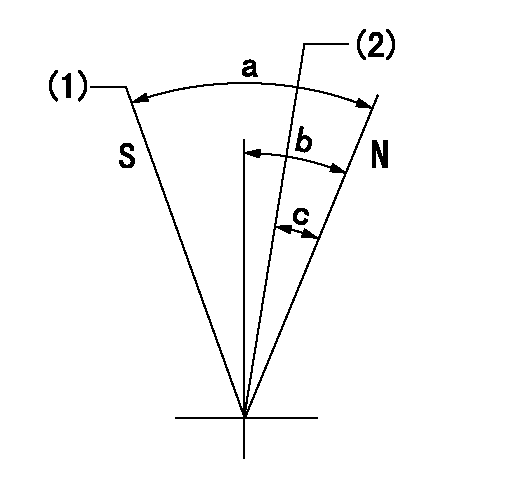

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=2.5mm bb=21mm

----------

a=71deg+-5deg b=20deg+-5deg c=(9.5deg)

----------

aa=2.5mm bb=21mm

----------

a=71deg+-5deg b=20deg+-5deg c=(9.5deg)

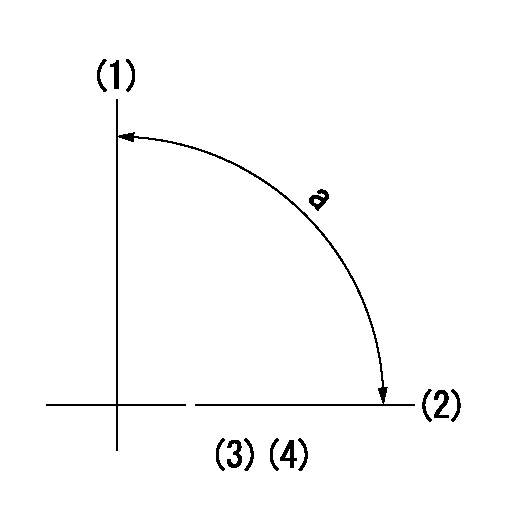

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '2' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(90deg)

----------

aa=16deg

----------

a=(90deg)

Information:

Coolant

To prevent personal injury, do not step up on engine to remove the filler cap, if applicable. Use an adequate ladder.At operating temperature, the engine coolant is hot and under pressure. The radiator and all lines to heaters or the engine contain hot water. When pressure is relieved rapidly, this hot water can turn into steam.Allow cooling system components to cool before draining.Any contact with hot water or steam can cause severe burns.Check the coolant level only after the engine has been stopped and the filler cap is cool enough to remove with your bare hand.Remove the cooling system filler cap slowly to relieve pressure.Cooling system supplemental additive contains alkali. To prevent personal injury, avoid contact with the skin and eyes and do not drink.Oils

Hot oil and components can cause personal injury. Do not allow hot oil or components to contact the skin.Batteries

Battery electrolyte contains acid and can cause injury. Avoid contact with the skin and eyes.Wash hands after touching batteries and connectors. Use of gloves is recommended.Batteries give off flammable fumes which can explode.Always thaw a frozen battery before jump starting. Frozen batteries can explode.Do not smoke when observing the battery electrolyte levels.Always wear protective glasses when working with batteries.Fire or Explosion Prevention

Determine whether the engine will be operated in an environment in which combustible gases could be drawn through the air inlet system. These gases could cause the engine to overspeed, which in turn could seriously damage the engine and result in bodily injury or property damage.If your application involves the presence of combustible gases, consult your Caterpillar dealer to obtain additional information concerning protection devices suitable for the application involved.Inhaling freon gas through a lit cigarette or other smoking method, or inhaling fumes released from a flame contacting freon could cause bodily harm or death. Do not smoke when servicing, charging or working around air conditioners or where freon gas may be present.All fuels, most lubricants and some coolant mixtures are flammable.Diesel fuel is flammable. Gasoline is flammable. The mixture of diesel and gasoline fumes are extremely explosive.Do not smoke while refueling or in a refueling area.Always thaw a frozen battery before jump starting. Frozen batteries can explode.Do not smoke in areas where batteries are charged, or where flammable materials are stored.Batteries give off flammable fumes which can explode.Keep all fuels and lubricants stored in properly marked containers and away from all unauthorized persons.Store all oily rags or other flammable material in a protective container, in a safe place.Do not weld or flame cut on pipes or tubes that contain flammable fluids. Clean them thoroughly with nonflammable solvent before welding or flame cutting on them.Remove all flammable materials such as fuel, oil and other debris before they accumulate on the truck engine.Do not expose the engine to flames, burning brush, etc., if at all possible.Exhaust shields (if equipped), which protect hot exhaust components from oil or fuel spray in the event of a line, tube or seal failure, must be installed correctly.Never disconnect any charging

To prevent personal injury, do not step up on engine to remove the filler cap, if applicable. Use an adequate ladder.At operating temperature, the engine coolant is hot and under pressure. The radiator and all lines to heaters or the engine contain hot water. When pressure is relieved rapidly, this hot water can turn into steam.Allow cooling system components to cool before draining.Any contact with hot water or steam can cause severe burns.Check the coolant level only after the engine has been stopped and the filler cap is cool enough to remove with your bare hand.Remove the cooling system filler cap slowly to relieve pressure.Cooling system supplemental additive contains alkali. To prevent personal injury, avoid contact with the skin and eyes and do not drink.Oils

Hot oil and components can cause personal injury. Do not allow hot oil or components to contact the skin.Batteries

Battery electrolyte contains acid and can cause injury. Avoid contact with the skin and eyes.Wash hands after touching batteries and connectors. Use of gloves is recommended.Batteries give off flammable fumes which can explode.Always thaw a frozen battery before jump starting. Frozen batteries can explode.Do not smoke when observing the battery electrolyte levels.Always wear protective glasses when working with batteries.Fire or Explosion Prevention

Determine whether the engine will be operated in an environment in which combustible gases could be drawn through the air inlet system. These gases could cause the engine to overspeed, which in turn could seriously damage the engine and result in bodily injury or property damage.If your application involves the presence of combustible gases, consult your Caterpillar dealer to obtain additional information concerning protection devices suitable for the application involved.Inhaling freon gas through a lit cigarette or other smoking method, or inhaling fumes released from a flame contacting freon could cause bodily harm or death. Do not smoke when servicing, charging or working around air conditioners or where freon gas may be present.All fuels, most lubricants and some coolant mixtures are flammable.Diesel fuel is flammable. Gasoline is flammable. The mixture of diesel and gasoline fumes are extremely explosive.Do not smoke while refueling or in a refueling area.Always thaw a frozen battery before jump starting. Frozen batteries can explode.Do not smoke in areas where batteries are charged, or where flammable materials are stored.Batteries give off flammable fumes which can explode.Keep all fuels and lubricants stored in properly marked containers and away from all unauthorized persons.Store all oily rags or other flammable material in a protective container, in a safe place.Do not weld or flame cut on pipes or tubes that contain flammable fluids. Clean them thoroughly with nonflammable solvent before welding or flame cutting on them.Remove all flammable materials such as fuel, oil and other debris before they accumulate on the truck engine.Do not expose the engine to flames, burning brush, etc., if at all possible.Exhaust shields (if equipped), which protect hot exhaust components from oil or fuel spray in the event of a line, tube or seal failure, must be installed correctly.Never disconnect any charging

Have questions with 101601-6781?

Group cross 101601-6781 ZEXEL

Mitsubishi

101601-6781

9 400 610 081

ME036846

INJECTION-PUMP ASSEMBLY

6D14

6D14