Information injection-pump assembly

ZEXEL

101601-6150

1016016150

MITSUBISHI

3096142010

3096142010

Rating:

Cross reference number

ZEXEL

101601-6150

1016016150

MITSUBISHI

3096142010

3096142010

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.2

2.15

2.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

112

107.3

116.7

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

11

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

112.3

109.9

114.7

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.2+-0.5

Pump speed

r/min

200

200

200

Average injection quantity

mm3/st.

10.7

8.1

13.3

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

12.8+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

113

113

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

400+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

1.8

1.3

2.3

Timer adjustment_03

Pump speed

r/min

1250

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

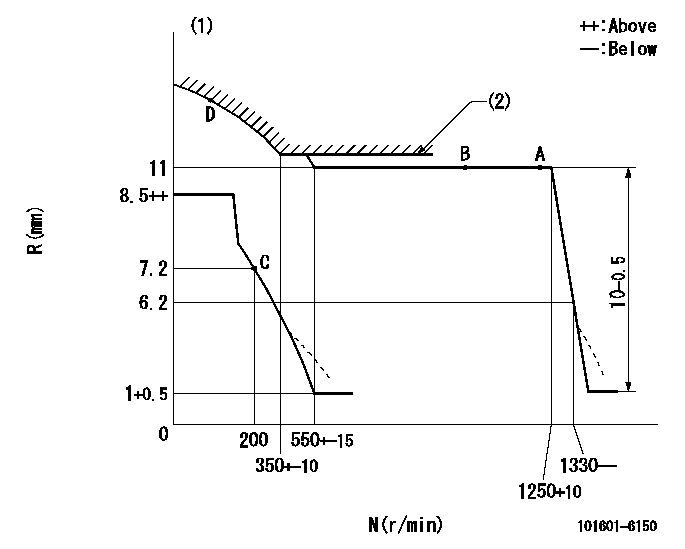

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Excess fuel setting for starting: SXL

----------

DL=4.5-0.2mm SXL=11+0.2mm

----------

----------

DL=4.5-0.2mm SXL=11+0.2mm

----------

0000000901

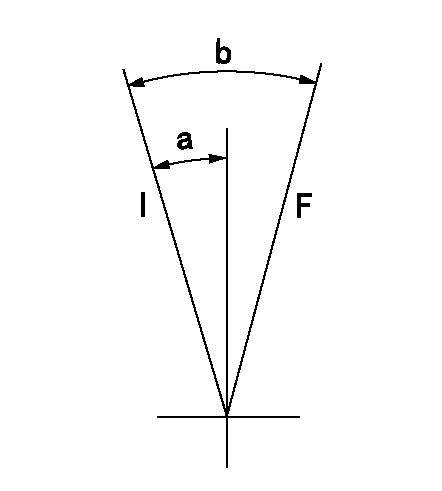

F:Full load

I:Idle

----------

----------

a=16deg+-5deg b=36deg+-3deg

----------

----------

a=16deg+-5deg b=36deg+-3deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325+-8r/min Ra=7.2mm

----------

----------

N1=325+-8r/min Ra=7.2mm

----------

Information:

Startability will be improved at temperatures below +32°F (0°C) by the use of a starting aid and/or use of a cylinder block coolant heater or other means to heat the crankcase oil.Start the engine using the following procedure:1. Place the transmission in NEUTRAL and disengage the flywheel clutch (if equipped) to remove the transmission drag and prevent movement of the truck. Depressing the clutch in cold weather can mean the difference between starting and not starting. Depressing the clutch in warm weather produces faster starts and reduces battery drain.2. Turn the ignition switch to the ON position and push the crank button or turn the ignition switch to the START position. Crank the engine. (At temperatures below +32°F (0°C), it may be necessary to spray starting fluid into the air cleaner inlet.) DO NOT PUSH DOWN OR HOLD THE THROTTLE DOWN while cranking the engine. The PEEC system will automatically provide the correct amount of fuel to start the engine. The PEEC equipped engine may need to crank slightly longer than a mechanically governed engine, because some oil pressure is required for the electronic actuator to move the rack. The "CHECK ENGINE" light should be ON while the engine is cranking, but should go OFF after engine oil pressure is achieved.If the engine fails to start in 30 seconds, release the starter switch and wait two minutes to allow the starter motor to cool before using it again.

When using starting fluid, follow the manufacturer's instructions carefully, use it sparingly and spray it only while cranking the engine. Also, do not store starting fluid containers in the cab. Failure to do so, could result in an explosion and/or fire and possible personal injury.

Excessive ether can cause piston and ring damage. Use ether for cold starting purposes only.

3. As soon as the engine starts, allow the engine to idle for two or three minutes, or until the water temperature gauge indicator has begun to rise.4. Do not apply load to the engine or increase engine speed until the oil pressure gauge indicates normal. Oil pressure should rise within 15 seconds after the engine starts.5. Operate the engine at low load until all systems reach operating temperature. Check all gauges during the warm-up period.Starting With Jumper Cables

Batteries give off flammable fumes that can explode. Improper jumper cable connections can cause an explosion resulting in personal injury.Prevent sparks near the batteries. Sparks could cause vapors to explode. Do not allow jumper cable ends to contact each other or the engine.Do not smoke when observing the battery electrolyte levels.Always wear protective glasses when working with batteries.Electrolyte is an acid and can cause personal injury if it contacts skin or eyes.

Engines installed without engine-to-frame ground straps can be damaged by electrical discharge.To prevent electrical discharge damage, check to make sure the engine's electrical system has an engine-to-frame ground strap. For engines which have the alternator connected to an engine component, the ground strap must connect that component to the frame.Some engines have starter-to-frame

When using starting fluid, follow the manufacturer's instructions carefully, use it sparingly and spray it only while cranking the engine. Also, do not store starting fluid containers in the cab. Failure to do so, could result in an explosion and/or fire and possible personal injury.

Excessive ether can cause piston and ring damage. Use ether for cold starting purposes only.

3. As soon as the engine starts, allow the engine to idle for two or three minutes, or until the water temperature gauge indicator has begun to rise.4. Do not apply load to the engine or increase engine speed until the oil pressure gauge indicates normal. Oil pressure should rise within 15 seconds after the engine starts.5. Operate the engine at low load until all systems reach operating temperature. Check all gauges during the warm-up period.Starting With Jumper Cables

Batteries give off flammable fumes that can explode. Improper jumper cable connections can cause an explosion resulting in personal injury.Prevent sparks near the batteries. Sparks could cause vapors to explode. Do not allow jumper cable ends to contact each other or the engine.Do not smoke when observing the battery electrolyte levels.Always wear protective glasses when working with batteries.Electrolyte is an acid and can cause personal injury if it contacts skin or eyes.

Engines installed without engine-to-frame ground straps can be damaged by electrical discharge.To prevent electrical discharge damage, check to make sure the engine's electrical system has an engine-to-frame ground strap. For engines which have the alternator connected to an engine component, the ground strap must connect that component to the frame.Some engines have starter-to-frame