Information injection-pump assembly

BOSCH

9 400 614 633

9400614633

ZEXEL

101601-5875

1016015875

HINO

220203753C

220203753c

Rating:

Service parts 101601-5875 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2350A

12.

Open Pre:MPa(Kqf/cm2)

157.{160}/21.6{220}

14.

NOZZLE

Cross reference number

BOSCH

9 400 614 633

9400614633

ZEXEL

101601-5875

1016015875

HINO

220203753C

220203753c

Zexel num

Bosch num

Firm num

Name

101601-5875

9 400 614 633

220203753C HINO

INJECTION-PUMP ASSEMBLY

W06D-TI K 14BF INJECTION PUMP ASSY PE6AD PE

W06D-TI K 14BF INJECTION PUMP ASSY PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-6420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.4

4.35

4.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.2

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

101.5

99.5

103.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

50.7

50.7

Boost pressure

mmHg

380

380

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.8+-0.5

Pump speed

r/min

265

265

265

Average injection quantity

mm3/st.

10

8.5

11.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

10.2

Boost pressure

kPa

4

1.3

6.7

Boost pressure

mmHg

30

10

50

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

11.7

Boost pressure

kPa

37.3

30.6

44

Boost pressure

mmHg

280

230

330

Timer adjustment

Pump speed

r/min

1350--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1300

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

1.5

1.2

1.8

Remarks

Finish

Finish

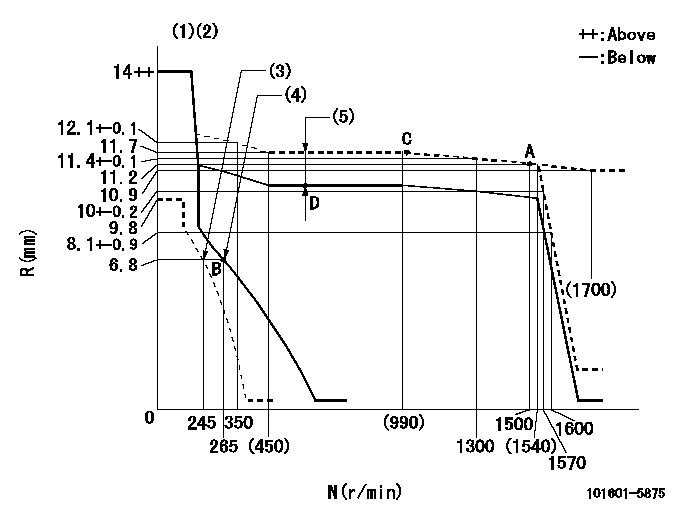

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Set idle sub-spring

(4)Main spring setting

(5)Boost compensator stroke: BCL

----------

K=12 BCL=1.5+-0.1mm

----------

----------

K=12 BCL=1.5+-0.1mm

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(12deg)+-5deg b=(27deg)+-5deg

----------

----------

a=(12deg)+-5deg b=(27deg)+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

(2)Normal

----------

aa=0r/min bb=1-0.2mm

----------

a=21deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.2mm

----------

a=21deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Adjustto conform and correspond to specifications.Checkto observe for satisfactory conditions, accuracy, safety or performance.Exchangeto trade a worn or failing component for a remanufactured or rebuilt component.Inspectto examine closely, in critical appraisal, while testing or evaluating components or systems.Inspect/Rebuild or Exchangeto examine closely; then making the decision on repair option (Rebuild or Exchange).Lubricateto apply a lubricant (oil, grease, etc.) as specified for reducing friction, heat and wear between solid surfaces.Protective Devicesindicators such as alarms, lights, emergency shutoffs, etc., that alert an operator that a potential problem may exist. Failure to respond to these indicators in a timely manner could result in serious engine damage.Rebuildto repair a worn or failing component with new parts, components and/or remanufactured components.Replaceto install something new, remanufactured or rebuilt in place of an existing worn or failing component.Service Hours (Electrical)records the time (clock hours) the engine is actually running but does not reflect variations in speed, load, etc. The Maintenance Schedules are developed for calendar time, clock hours or fuel consumption. Hours are expressed in clock hours, not service meter units (unless the service meter is a clock hour device). Hours of operation include only the time that the engine is running. An electric clock device should be connected so it is OFF when the engine is not running. Caterpillar recommends that fuel consumption be used as the preferred method of establishing intervals rather than time or clock hours.Maintenance Intervals

The Maintenance Schedule requires all previous interval maintenance items to be performed first. For instance, if the Every 250 Hour maintenance is being done, then the Daily and Every 250 Hour maintenance items must be completed BEFORE performing the Every 1000 Hour maintenance.Engines may be equipped with various optional components and the Schedule may recommend maintenance for items not installed on your engine. Simply disregard reference to any extraneous items. If unsure of any item, consult your Caterpillar dealer.Overhaul Interval

One interval for some engines is labeled Top End because it involves removal, inspection, and rework of the cylinder head components. This interval is dependent on load-sensitive items/total amount of fuel consumed.The last interval in each chart lists the components inspected, rebuilt, exchanged or replaced at overhaul. Overhaul is defined as the interval at which the major wear items in the engine should be replaced. The intervals represent maintenance of a non-failed engine. In other words, the engine is being rebuilt with certain new parts replacing worn parts such as piston rings, engine rod and main bearings, valves and valve seats., etc.Incidental to the replacement of these relatively few parts is the complete inspection of all other parts that are visible during the overhaul of the engine. The disassembly required to do an overhaul means that disturbed seals and gaskets, etc., will be replaced, and the internal passages of the engine and block be cleaned.* The Overhaul interval assumes that regular maintenance recommendations in the rest of the chart have been carefully followed.* Some users may obtain significantly longer or shorter life than the chart recommends

The Maintenance Schedule requires all previous interval maintenance items to be performed first. For instance, if the Every 250 Hour maintenance is being done, then the Daily and Every 250 Hour maintenance items must be completed BEFORE performing the Every 1000 Hour maintenance.Engines may be equipped with various optional components and the Schedule may recommend maintenance for items not installed on your engine. Simply disregard reference to any extraneous items. If unsure of any item, consult your Caterpillar dealer.Overhaul Interval

One interval for some engines is labeled Top End because it involves removal, inspection, and rework of the cylinder head components. This interval is dependent on load-sensitive items/total amount of fuel consumed.The last interval in each chart lists the components inspected, rebuilt, exchanged or replaced at overhaul. Overhaul is defined as the interval at which the major wear items in the engine should be replaced. The intervals represent maintenance of a non-failed engine. In other words, the engine is being rebuilt with certain new parts replacing worn parts such as piston rings, engine rod and main bearings, valves and valve seats., etc.Incidental to the replacement of these relatively few parts is the complete inspection of all other parts that are visible during the overhaul of the engine. The disassembly required to do an overhaul means that disturbed seals and gaskets, etc., will be replaced, and the internal passages of the engine and block be cleaned.* The Overhaul interval assumes that regular maintenance recommendations in the rest of the chart have been carefully followed.* Some users may obtain significantly longer or shorter life than the chart recommends

Have questions with 101601-5875?

Group cross 101601-5875 ZEXEL

Hino

101601-5875

9 400 614 633

220203753C

INJECTION-PUMP ASSEMBLY

W06D-TI

W06D-TI