Information injection-pump assembly

BOSCH

9 400 614 632

9400614632

ZEXEL

101601-5860

1016015860

HINO

220203800A

220203800a

Rating:

Service parts 101601-5860 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2133

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Include in #1:

101601-5860

as INJECTION-PUMP ASSEMBLY

Include in #2:

104139-4001

as _

Cross reference number

BOSCH

9 400 614 632

9400614632

ZEXEL

101601-5860

1016015860

HINO

220203800A

220203800a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.8

3.77

3.83

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

9.5

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

98.4

96.4

100.4

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.1+-0.5

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

10

9

11

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Timer adjustment

Pump speed

r/min

925--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

875

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1250

Advance angle

deg.

3.5

3

4

Remarks

Finish

Finish

Test data Ex:

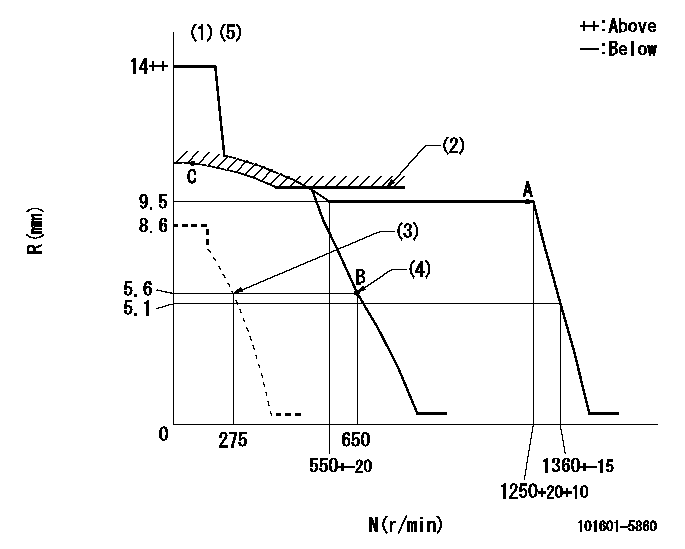

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)SMA RACK LIMIT; RAL

(3)Set idle sub-spring

(4)Main spring setting

(5)Perform governor adjustment at an ambient temperature of at least 15 deg C (rack limit spring is shape memory alloy).

----------

K=12 RAL=9.7+0.2mm

----------

----------

K=12 RAL=9.7+0.2mm

----------

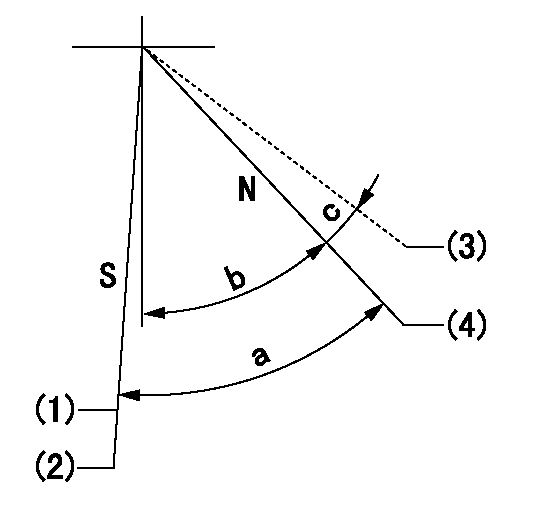

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=18deg+-5deg

----------

----------

a=10deg+-5deg b=18deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position aa or less, pump speed bb

(2)At shipping

(3)Contacts normal side pin

(4)Clearance from the pin on the normal side: cc

----------

aa=5.1mm bb=0r/min cc=2.5+-0.5mm

----------

a=53deg+-5deg b=51deg+-5deg c=(6deg)

----------

aa=5.1mm bb=0r/min cc=2.5+-0.5mm

----------

a=53deg+-5deg b=51deg+-5deg c=(6deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Engine Oil Pressure

The sensor utilizes engine oil pressure and engine speed to perform low engine oil pressure detection for diagnostic and annunciation.The graph below illustrates the limits of low engine oil pressure diagnostic and annunciation. The output from the ECM can be used to drive a relay or a lamp to annunciate Low Oil Pressure conditions.

Oil Pressure ParametersLow Oil Pressure Alarm

Oil pressure sensor location.The sensor is mounted in the front of the engine cylinder block with oil lines connected to the switch. Low engine oil pressure closes the switch.The oil pressure switch senses oil pressure at the bearing oil gallery. No resetting procedure is required. Switches may close at 48 to 62 kPa (7 to 9 psi) below actual trip point.Oil Pressure Sensor Failure

When the sensor output is open, shorted to ground or supply, or measured oil pressure reading is out of specification, a sensor failure may have occurred.The ECM will detect the oil pressure sensor failure and through the diagnostic lamp warn the user about the oil pressure sensor failure. The oil pressure related strategies will be disabled. The oil pressure sensor failure will not cause an engine shut down, power derating, or any engine speed change.Speed Sensing Loss Alarm

When the engine speed sensor can no longer sense engine speed, an alarm and diagnostic code entry will occur. If the ECM can not detect any engine speed, the engine will shut down.Manual Fuel Shutoff Lever

Do not use the emergency shutoff control for a normal stopping procedure.

Manual shutdown shaft with lever location.A manual shutdown shaft is provided to override the governor solenoid. This shutdown will only move the fuel control linkage to the fuel OFF position to starve the engine of fuel. It does not shut off the air inlet.Engine Shutoff Controls

Secondary shutoff controls may be electrically, mechanically or hydraulically operated. Familiarize yourself with the types and locations of the shutoff controls, the conditions which cause each control to function, and the resetting procedure required to start your engine.The shutoff controls should be tested every 1000 hours by authorized Caterpillar dealer personnel.Always determine the cause of the shutdown, and have the necessary repairs made before restarting the engine.Shutoff Solenoid Failure

When the shutoff solenoid output is open or shorted to ground or supply, a failure may have occurred.The ECM will detect open or short condition of the shutoff solenoid. If the solenoid is failed "open", the engine will shut down.The shutoff solenoid failure will cause the engine to shut down, but the pilot or service personnel can mechanically reposition the shutoff solenoid and restart the engine.Cold Start Strategy

This feature utilizes the coolant temperature sensor input to improve low temperature engine starting and warm-up. It provides quicker cold starts, smoke cleanup, reduces battery "deep" cycling and extends engine life. The engine timing is fixed at 19.5 degrees. Engine block heaters are provided to maintain minimum engine temperature when the engine is not running.When the coolant temperature is below 60°C (140°F), the cold start strategy is activated using the following parameters

The sensor utilizes engine oil pressure and engine speed to perform low engine oil pressure detection for diagnostic and annunciation.The graph below illustrates the limits of low engine oil pressure diagnostic and annunciation. The output from the ECM can be used to drive a relay or a lamp to annunciate Low Oil Pressure conditions.

Oil Pressure ParametersLow Oil Pressure Alarm

Oil pressure sensor location.The sensor is mounted in the front of the engine cylinder block with oil lines connected to the switch. Low engine oil pressure closes the switch.The oil pressure switch senses oil pressure at the bearing oil gallery. No resetting procedure is required. Switches may close at 48 to 62 kPa (7 to 9 psi) below actual trip point.Oil Pressure Sensor Failure

When the sensor output is open, shorted to ground or supply, or measured oil pressure reading is out of specification, a sensor failure may have occurred.The ECM will detect the oil pressure sensor failure and through the diagnostic lamp warn the user about the oil pressure sensor failure. The oil pressure related strategies will be disabled. The oil pressure sensor failure will not cause an engine shut down, power derating, or any engine speed change.Speed Sensing Loss Alarm

When the engine speed sensor can no longer sense engine speed, an alarm and diagnostic code entry will occur. If the ECM can not detect any engine speed, the engine will shut down.Manual Fuel Shutoff Lever

Do not use the emergency shutoff control for a normal stopping procedure.

Manual shutdown shaft with lever location.A manual shutdown shaft is provided to override the governor solenoid. This shutdown will only move the fuel control linkage to the fuel OFF position to starve the engine of fuel. It does not shut off the air inlet.Engine Shutoff Controls

Secondary shutoff controls may be electrically, mechanically or hydraulically operated. Familiarize yourself with the types and locations of the shutoff controls, the conditions which cause each control to function, and the resetting procedure required to start your engine.The shutoff controls should be tested every 1000 hours by authorized Caterpillar dealer personnel.Always determine the cause of the shutdown, and have the necessary repairs made before restarting the engine.Shutoff Solenoid Failure

When the shutoff solenoid output is open or shorted to ground or supply, a failure may have occurred.The ECM will detect open or short condition of the shutoff solenoid. If the solenoid is failed "open", the engine will shut down.The shutoff solenoid failure will cause the engine to shut down, but the pilot or service personnel can mechanically reposition the shutoff solenoid and restart the engine.Cold Start Strategy

This feature utilizes the coolant temperature sensor input to improve low temperature engine starting and warm-up. It provides quicker cold starts, smoke cleanup, reduces battery "deep" cycling and extends engine life. The engine timing is fixed at 19.5 degrees. Engine block heaters are provided to maintain minimum engine temperature when the engine is not running.When the coolant temperature is below 60°C (140°F), the cold start strategy is activated using the following parameters