Information injection-pump assembly

BOSCH

9 400 614 629

9400614629

ZEXEL

101601-5802

1016015802

HINO

220007421A

220007421a

Rating:

Service parts 101601-5802 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

19.6(220)

15.

NOZZLE SET

Include in #1:

101601-5802

as INJECTION-PUMP ASSEMBLY

Include in #2:

104207-3002

as _

Cross reference number

BOSCH

9 400 614 629

9400614629

ZEXEL

101601-5802

1016015802

HINO

220007421A

220007421a

Zexel num

Bosch num

Firm num

Name

101601-5802

9 400 614 629

220007421A HINO

INJECTION-PUMP ASSEMBLY

W06D K

W06D K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.07

3.13

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

8.7

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

44.4

42.4

46.4

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

8+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

8

6.5

9.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(8.7)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

44.4

43.4

45.4

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.3

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

43.5

41.5

45.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.1

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

44.1

42.1

46.1

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

D

Rack position

R1-0.2

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

36.2

34.2

38.2

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1300+50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1600

Advance angle

deg.

5

4.7

5.3

Remarks

Finish

Finish

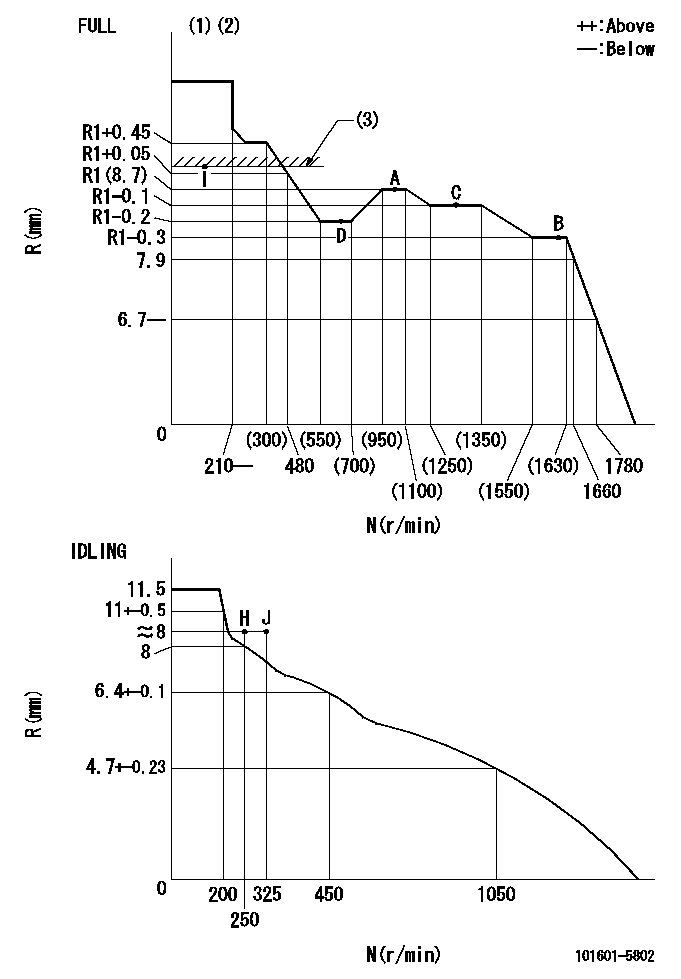

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT: RAL

----------

T1=93 RAL=[R1+0.2]+0.2mm

----------

----------

T1=93 RAL=[R1+0.2]+0.2mm

----------

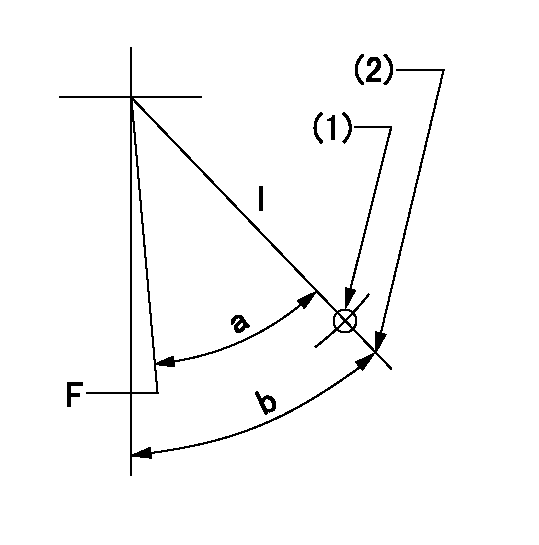

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=55mm

----------

a=33deg+-3deg b=34deg+-5deg

----------

aa=55mm

----------

a=33deg+-3deg b=34deg+-5deg

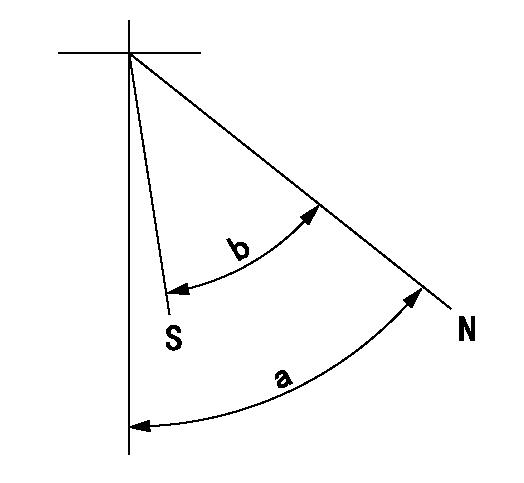

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=40deg+-5deg b=40deg+-5deg

----------

----------

a=40deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Engine Model View

3408 Engine Shown

Turbochargers (1), Exhaust Outlet (2), Crankcase Breather (3), Lifting Eye (4), Flywheel (5), Magnetic Pickup (6), Electronic Control Module (ECM) (7), Oil Fill Tube (8), Thermostat (9), Primary Fuel Filter (10), Water Pump (11), Crankshaft Vibration Damper (12), Alternator (13), Oil Filters (14), Crankcase Drain Plug (15), Fuel Filters and Priming Pump (16).3408 Engine Description

Caterpillar 3408 electronically controlled Industrial Engines are 18 liter (1099 cu in), 137 mm (5.4 in) bore and 152.4 mm (6.0 in) stroke, four cycle, 8 cylinder, 65 degree vee diesel design. The engine is twin turbocharged with jacket water aftercooling and direct fuel injection. It is designed for petroleum and auxiliary industrial applications.The engine and components are designed for high power output. The reduced size and weight plus increased fuel economy provide maximum performance. Contact your Caterpillar dealer for information on power ratings.Larger diameter plungers and a higher injection rate camshaft are incorporated in the valve train/fuel system. The fuel lines are made of high strength steel and the ends of the lines have collared washers to increase reliability.The cooling system has a gear driven centrifugal water pump, two thermostats (one for each bank) which regulate engine coolant temperature, and an oil cooler. A customer supplied fan drive and cooling system (radiator) may be required for the industrial

3408 Engine Shown

Turbochargers (1), Exhaust Outlet (2), Crankcase Breather (3), Lifting Eye (4), Flywheel (5), Magnetic Pickup (6), Electronic Control Module (ECM) (7), Oil Fill Tube (8), Thermostat (9), Primary Fuel Filter (10), Water Pump (11), Crankshaft Vibration Damper (12), Alternator (13), Oil Filters (14), Crankcase Drain Plug (15), Fuel Filters and Priming Pump (16).3408 Engine Description

Caterpillar 3408 electronically controlled Industrial Engines are 18 liter (1099 cu in), 137 mm (5.4 in) bore and 152.4 mm (6.0 in) stroke, four cycle, 8 cylinder, 65 degree vee diesel design. The engine is twin turbocharged with jacket water aftercooling and direct fuel injection. It is designed for petroleum and auxiliary industrial applications.The engine and components are designed for high power output. The reduced size and weight plus increased fuel economy provide maximum performance. Contact your Caterpillar dealer for information on power ratings.Larger diameter plungers and a higher injection rate camshaft are incorporated in the valve train/fuel system. The fuel lines are made of high strength steel and the ends of the lines have collared washers to increase reliability.The cooling system has a gear driven centrifugal water pump, two thermostats (one for each bank) which regulate engine coolant temperature, and an oil cooler. A customer supplied fan drive and cooling system (radiator) may be required for the industrial

Have questions with 101601-5802?

Group cross 101601-5802 ZEXEL

Hino

Hino

101601-5802

9 400 614 629

220007421A

INJECTION-PUMP ASSEMBLY

W06D

W06D