Information injection-pump assembly

BOSCH

F 01G 09U 02Z

f01g09u02z

ZEXEL

101601-5781

1016015781

HINO

220007291A

220007291a

Rating:

Service parts 101601-5781 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2142A

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

BOSCH

F 01G 09U 02Z

f01g09u02z

ZEXEL

101601-5781

1016015781

HINO

220007291A

220007291a

Zexel num

Bosch num

Firm num

Name

F 01G 09U 02Z

220007291A HINO

INJECTION-PUMP ASSEMBLY

W06E A * K 14BE PE6A PE

W06E A * K 14BE PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.45

3.42

3.48

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

11.3

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

63.5

61.5

65.5

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.3+-0.5

Pump speed

r/min

250

250

250

Each cylinder's injection qty

mm3/st.

17.1

16.1

18.1

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.3)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

63.5

62.5

64.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(11.3)

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

67.4

63.4

71.4

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.35

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

49.6

45.6

53.6

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

123

123

133

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

960--

Advance angle

deg.

0

0

0

Load

1/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

910

Advance angle

deg.

0.3

Load

1/4

Timer adjustment_03

Pump speed

r/min

1010

Advance angle

deg.

1

0.7

1.3

Load

4/4

Timer adjustment_04

Pump speed

r/min

1210

Advance angle

deg.

1

0.7

1.3

Load

3/4

Timer adjustment_05

Pump speed

r/min

1510

Advance angle

deg.

6

5.7

6.3

Load

4/4

Remarks

Finish

Finish

Test data Ex:

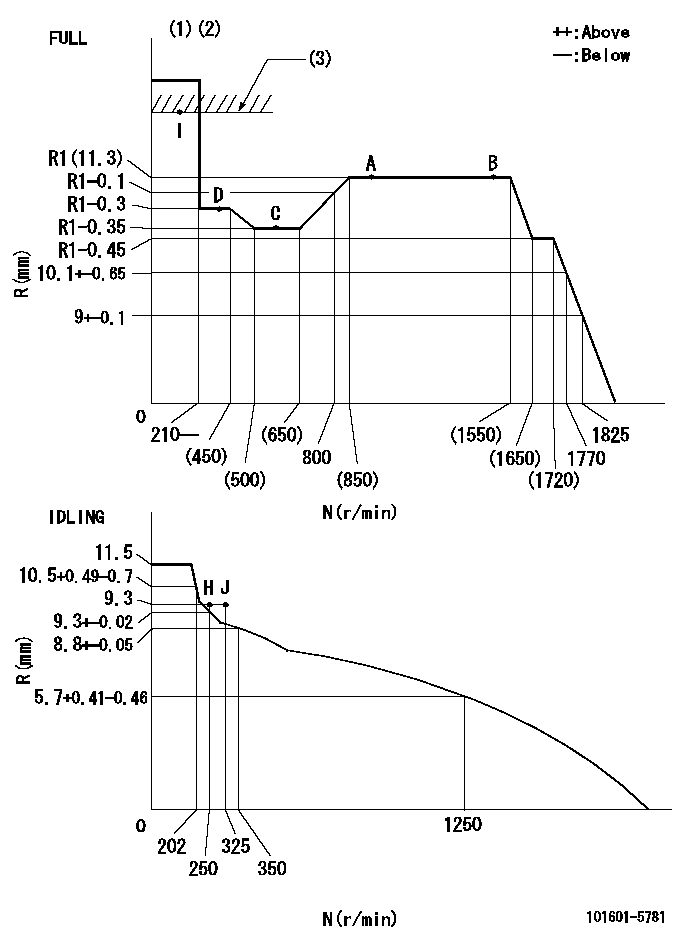

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=F50

----------

----------

T1=F50

----------

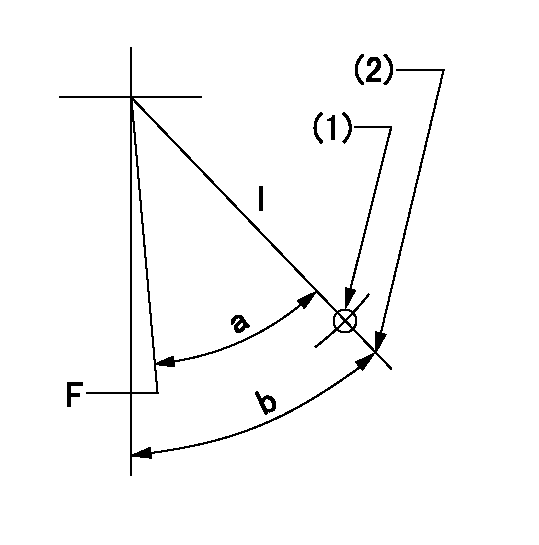

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=55mm

----------

a=32.5deg+-3deg b=34deg+-5deg

----------

aa=55mm

----------

a=32.5deg+-3deg b=34deg+-5deg

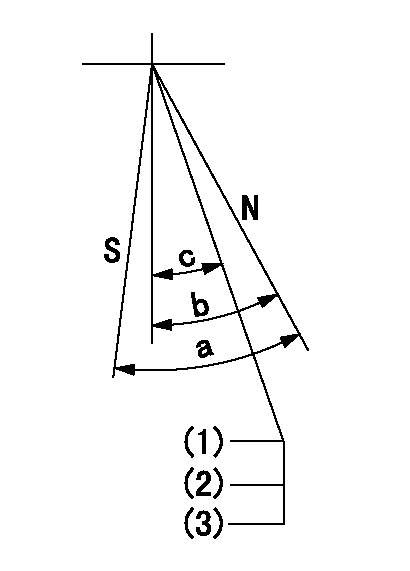

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Set the stopper bolt. (After setting, apply red paint.)

(3)Engine normal

----------

aa=17+-0.1mm

----------

a=40deg+-5deg b=40deg+-5deg c=(35deg)

----------

aa=17+-0.1mm

----------

a=40deg+-5deg b=40deg+-5deg c=(35deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Replace:

Thrust, Main and Rod Bearings, Valve Rotators, Thermostat and Throttle Position SensorIn most probability, these components will not last until the second overhaul. Therefore, Caterpillar recommends the installation of these components new at each overhaul period.Inspect:

Crankshaft, Camshaft, Camshaft Followers, Vibration Damper, Spacer Block, Oil Pump and Fuel Transfer PumpThe ideal time for inspecting your crankshaft, camshaft and vibration damper is while the engine is disassembled for overhaul. Inspect each component for potential damage as follows:Crankshaft - Inspect for bend, journal damage and bearing material seized to the journal. At the same time, check the taper and profile of the crankshaft journals by interpreting your main and rod bearing wear patterns. In case of an out-of-frame overhaul, use the magnetic particle inspection process to check the crankshaft for cracks.* Camshaft - Inspect the camshaft for journal damage. In case of an out-of-frame overhaul, use the magnetic particle inspection process to check the camshaft for cracks.* Camshaft Followers - For out-of-frame overhaul, inspect the cam bearing for fatigue and wear.* Vibration Damper - Inspect the damper for rubber deterioration and movement of the outer ring relative to the inner hub.* Spacer Block - Inspect the spacer block for excessive wear or warping. For additional information regarding these components, contact your local Caterpillar dealer for assistance.Test:

Electronic Unit Injectors For additional information regarding this component, contact your local Caterpillar dealer for assistance.Clean/Test:

Oil Cooler Core and Aftercooler CoreCaterpillar recommends that the oil cooler core and the air-to-air aftercooler core be cleaned and pressure tested at each overhaul. For additional specifications and/or pressure test information, contact your local Caterpillar dealer.Cleaning Procedure for Air-to-Air Aftercooler

Caterpillar recommends that the air-to-air aftercooler core be removed, cleaned, and tested at overhaul time, if a turbocharger failure has occurred, or if at any time the turbocharger develops an oil leak.To clean the air-to-air aftercooler system:1. Remove the air-to-air aftercooler core. Turn the core upside down to remove debris from the inlet tank.

Do not use caustic cleaners to clean the air-to-air aftercooler core. Caustic cleaners will attack the internal metals of the core and cause leakage.

2. Back flush internally with a solvent to loosen foreign substances and to remove oil.Caterpillar recommends the use of Caterpillar Hydrosolv 4165 or Hydrosolv 100 Liquid Cleaners. For more information see "General Instructions and Application Guide" Form LEHQ6101 or contact your Caterpillar dealer.3. Shake the core vigorously to eliminate any trapped debris.4. Wash the core with hot, soapy water. Rinse thoroughly with clean water.

The maximum air pressure must not be above 30 psi (205 kPa) for cleaning purposes.

5. Dry the core with compressed air. Blow air in reverse direction of normal flow. Use all necessary safety equipment while using compressed air.6. Inspect the system to ensure cleanliness and install the air-to-air aftercooler core.Caterpillar Recommendation

The "repair before failure" concept makes sense. It saves money, lowers operating costs and minimizes downtime.As previously illustrated, it is not cheaper to operate the truck until an engine component fails, since failing components may increase fuel costs and upon failure, could

Thrust, Main and Rod Bearings, Valve Rotators, Thermostat and Throttle Position SensorIn most probability, these components will not last until the second overhaul. Therefore, Caterpillar recommends the installation of these components new at each overhaul period.Inspect:

Crankshaft, Camshaft, Camshaft Followers, Vibration Damper, Spacer Block, Oil Pump and Fuel Transfer PumpThe ideal time for inspecting your crankshaft, camshaft and vibration damper is while the engine is disassembled for overhaul. Inspect each component for potential damage as follows:Crankshaft - Inspect for bend, journal damage and bearing material seized to the journal. At the same time, check the taper and profile of the crankshaft journals by interpreting your main and rod bearing wear patterns. In case of an out-of-frame overhaul, use the magnetic particle inspection process to check the crankshaft for cracks.* Camshaft - Inspect the camshaft for journal damage. In case of an out-of-frame overhaul, use the magnetic particle inspection process to check the camshaft for cracks.* Camshaft Followers - For out-of-frame overhaul, inspect the cam bearing for fatigue and wear.* Vibration Damper - Inspect the damper for rubber deterioration and movement of the outer ring relative to the inner hub.* Spacer Block - Inspect the spacer block for excessive wear or warping. For additional information regarding these components, contact your local Caterpillar dealer for assistance.Test:

Electronic Unit Injectors For additional information regarding this component, contact your local Caterpillar dealer for assistance.Clean/Test:

Oil Cooler Core and Aftercooler CoreCaterpillar recommends that the oil cooler core and the air-to-air aftercooler core be cleaned and pressure tested at each overhaul. For additional specifications and/or pressure test information, contact your local Caterpillar dealer.Cleaning Procedure for Air-to-Air Aftercooler

Caterpillar recommends that the air-to-air aftercooler core be removed, cleaned, and tested at overhaul time, if a turbocharger failure has occurred, or if at any time the turbocharger develops an oil leak.To clean the air-to-air aftercooler system:1. Remove the air-to-air aftercooler core. Turn the core upside down to remove debris from the inlet tank.

Do not use caustic cleaners to clean the air-to-air aftercooler core. Caustic cleaners will attack the internal metals of the core and cause leakage.

2. Back flush internally with a solvent to loosen foreign substances and to remove oil.Caterpillar recommends the use of Caterpillar Hydrosolv 4165 or Hydrosolv 100 Liquid Cleaners. For more information see "General Instructions and Application Guide" Form LEHQ6101 or contact your Caterpillar dealer.3. Shake the core vigorously to eliminate any trapped debris.4. Wash the core with hot, soapy water. Rinse thoroughly with clean water.

The maximum air pressure must not be above 30 psi (205 kPa) for cleaning purposes.

5. Dry the core with compressed air. Blow air in reverse direction of normal flow. Use all necessary safety equipment while using compressed air.6. Inspect the system to ensure cleanliness and install the air-to-air aftercooler core.Caterpillar Recommendation

The "repair before failure" concept makes sense. It saves money, lowers operating costs and minimizes downtime.As previously illustrated, it is not cheaper to operate the truck until an engine component fails, since failing components may increase fuel costs and upon failure, could