Information injection-pump assembly

BOSCH

F 019 Z10 819

f019z10819

ZEXEL

101601-5780

1016015780

HINO

220007290A

220007290a

Rating:

Service parts 101601-5780 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

19.6(200)

15.

NOZZLE SET

Cross reference number

BOSCH

F 019 Z10 819

f019z10819

ZEXEL

101601-5780

1016015780

HINO

220007290A

220007290a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.45

3.42

3.48

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

11.3

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

63.5

61.5

65.5

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.3+-0.5

Pump speed

r/min

250

250

250

Each cylinder's injection qty

mm3/st.

17.1

16.1

18.1

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.3)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

63.5

62.5

64.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(11.3)

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

67.4

63.4

71.4

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.35

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

49.6

45.6

53.6

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

123

123

133

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Load

1/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.3

Load

1/4

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

1

0.7

1.3

Load

4/4

Timer adjustment_04

Pump speed

r/min

1200

Advance angle

deg.

1

0.7

1.3

Load

3/4

Timer adjustment_05

Pump speed

r/min

1500

Advance angle

deg.

6

5.7

6.3

Load

4/4

Remarks

Finish

Finish

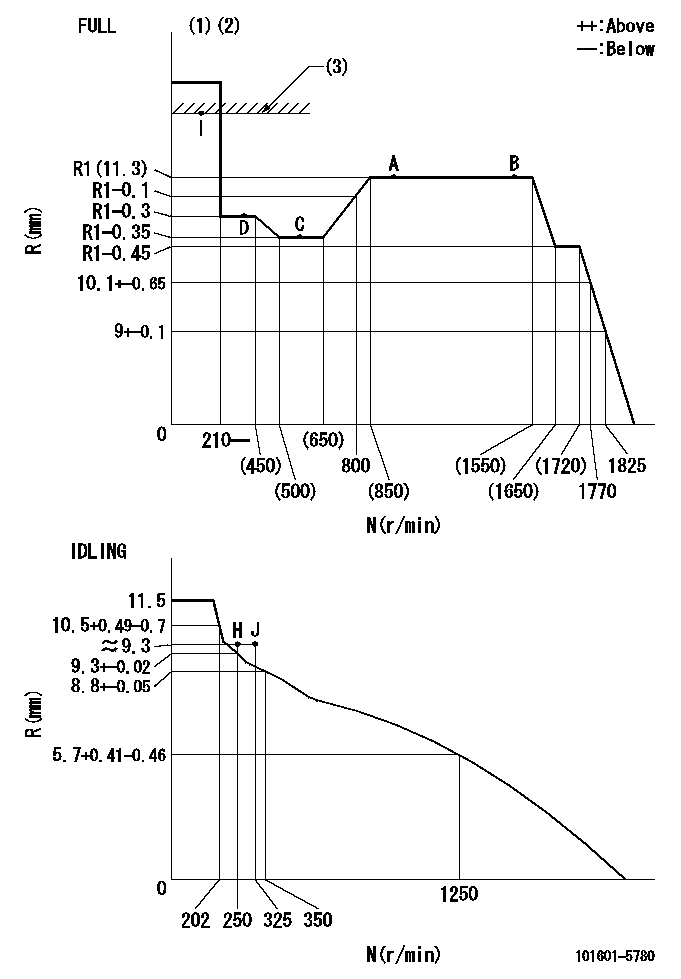

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=F50

----------

----------

T1=F50

----------

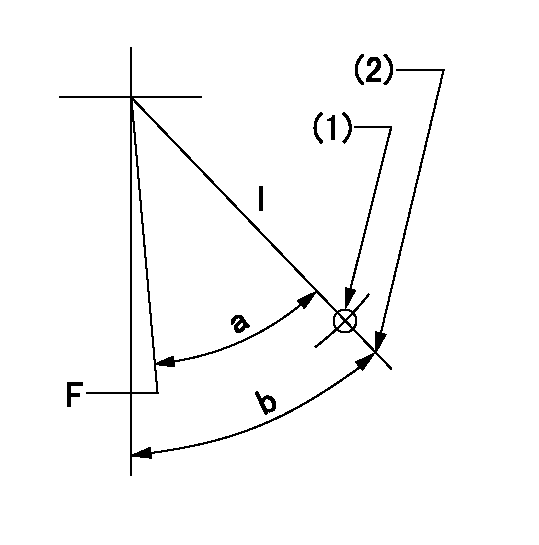

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=55mm

----------

a=32.5deg+-3deg b=34deg+-5deg

----------

aa=55mm

----------

a=32.5deg+-3deg b=34deg+-5deg

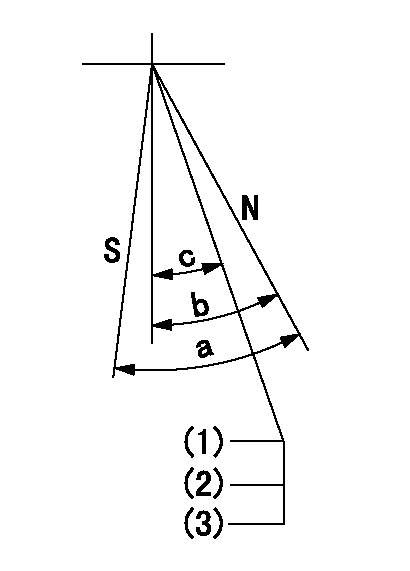

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Set the stopper bolt. (After setting, apply red paint.)

(3)Engine normal

----------

aa=17+-0.1mm

----------

a=40deg+-5deg b=40deg+-5deg c=(35deg)

----------

aa=17+-0.1mm

----------

a=40deg+-5deg b=40deg+-5deg c=(35deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

All PM Level 3 maintenance is to be performed at the intervals specified in the Maintenance Management Schedule.Before proceeding with PM Level 3 maintenance, perform all PM Level 2, PM Level 1 and Daily maintenance requirements. You must read and understand the warnings and instructions contained in the Safety section of this manual before performing any operation or maintenance procedures.Air Compressor

Rebuild or Exchange

Visually check for fluid leaks.Our recommendation to maintain your air compressor before it fails will be less costly than repairing the air compressor after failure.If the engine is operated until the air compressor fails, additional damage to the engine could result. For example: A failed air compressor could contaminate the engine oil with particles of materials since engine oil also lubricates the air compressor. The circulation of these engine oil with particles of materials since engine oil also lubricates the air compressor. The circulation of these contaminates through the engine lubricating system could damage the engine's main and connecting rod bearings.Maintenance Options

Repair Kits - These useful kits can be obtained from your Caterpillar dealer. These kits include all the necessary parts, special tools and instructions to repair your air compressor in either your own maintenance shop or at your servicing dealer's facility. Repair kits simplify parts ordering, help speed repairs and reduce parts cost. Exchange - This is a cost cutting service that permits exchanging a worn air compressor for a dealer or OEM factory rebuilt air compressor on an over-the-counter basis. They are available when needed at a substantial savings in both time and money. New - Replace with a new air compressor.Caterpillar Recommendation

The most cost effective repair option is to rebuild the air compressor with a repair kit that can be obtained from your Caterpillar dealer.Refer to the Service Manual for your engine to remove and install the air compressor.Turbocharger

Rebuild or Exchange

The cost incurred to maintain your turbocharger before failure as recommended could be significantly less than if you wait until your turbocharger fails.By maintaining your turbocharger before failure, you will minimize unscheduled downtime and reduce the chances for potential damage to other engine parts. When you reduce the risk of unscheduled downtime and costly repairs, you conserve cash that can be budgeted for use more profitably elsewhere.If you choose to operate your engine until the turbocharger fails, your repair costs could be as much as twenty-five times or more compared to the repair before failure cost. This excessive cost is due to additional engine damage that could have been prevented.If the engine is operated until the turbocharger fails, severe damage to the turbocharger's compressor wheel and/or engine could result.For example: severe damage to the turbocharger compressor wheel could cause parts from the compressor wheel to enter the engine cylinder that could result in cracks in the cylinder head and cause additional damage to the piston, a piston seizure orother potential damage to valves and cylinder head.Our recommended maintenance intervals for performing preventive maintenance on your turbocharger are based on experience and gathered

Rebuild or Exchange

Visually check for fluid leaks.Our recommendation to maintain your air compressor before it fails will be less costly than repairing the air compressor after failure.If the engine is operated until the air compressor fails, additional damage to the engine could result. For example: A failed air compressor could contaminate the engine oil with particles of materials since engine oil also lubricates the air compressor. The circulation of these engine oil with particles of materials since engine oil also lubricates the air compressor. The circulation of these contaminates through the engine lubricating system could damage the engine's main and connecting rod bearings.Maintenance Options

Repair Kits - These useful kits can be obtained from your Caterpillar dealer. These kits include all the necessary parts, special tools and instructions to repair your air compressor in either your own maintenance shop or at your servicing dealer's facility. Repair kits simplify parts ordering, help speed repairs and reduce parts cost. Exchange - This is a cost cutting service that permits exchanging a worn air compressor for a dealer or OEM factory rebuilt air compressor on an over-the-counter basis. They are available when needed at a substantial savings in both time and money. New - Replace with a new air compressor.Caterpillar Recommendation

The most cost effective repair option is to rebuild the air compressor with a repair kit that can be obtained from your Caterpillar dealer.Refer to the Service Manual for your engine to remove and install the air compressor.Turbocharger

Rebuild or Exchange

The cost incurred to maintain your turbocharger before failure as recommended could be significantly less than if you wait until your turbocharger fails.By maintaining your turbocharger before failure, you will minimize unscheduled downtime and reduce the chances for potential damage to other engine parts. When you reduce the risk of unscheduled downtime and costly repairs, you conserve cash that can be budgeted for use more profitably elsewhere.If you choose to operate your engine until the turbocharger fails, your repair costs could be as much as twenty-five times or more compared to the repair before failure cost. This excessive cost is due to additional engine damage that could have been prevented.If the engine is operated until the turbocharger fails, severe damage to the turbocharger's compressor wheel and/or engine could result.For example: severe damage to the turbocharger compressor wheel could cause parts from the compressor wheel to enter the engine cylinder that could result in cracks in the cylinder head and cause additional damage to the piston, a piston seizure orother potential damage to valves and cylinder head.Our recommended maintenance intervals for performing preventive maintenance on your turbocharger are based on experience and gathered