Information injection-pump assembly

BOSCH

9 400 614 626

9400614626

ZEXEL

101601-5762

1016015762

HINO

220007151A

220007151a

Rating:

Service parts 101601-5762 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 626

9400614626

ZEXEL

101601-5762

1016015762

HINO

220007151A

220007151a

Zexel num

Bosch num

Firm num

Name

101601-5762

9 400 614 626

220007151A HINO

INJECTION-PUMP ASSEMBLY

W06E K

W06E K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.07

3.13

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

9.2

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

52.4

50.4

54.4

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

8+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

6.8

5.3

8.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.2)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

52.4

51.4

53.4

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.35

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

48.8

44.8

52.8

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.35

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

36.5

32.5

40.5

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

D

Rack position

R1-0.1

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

53.1

49.1

57.1

Fixing the lever

*

Injection quantity adjustment_07

Adjusting point

E

Rack position

R1+0.2

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

29.2

25.2

33.2

Fixing the lever

*

Injection quantity adjustment_08

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

99

99

109

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1050--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

4.5

4.2

4.8

Remarks

Finish

Finish

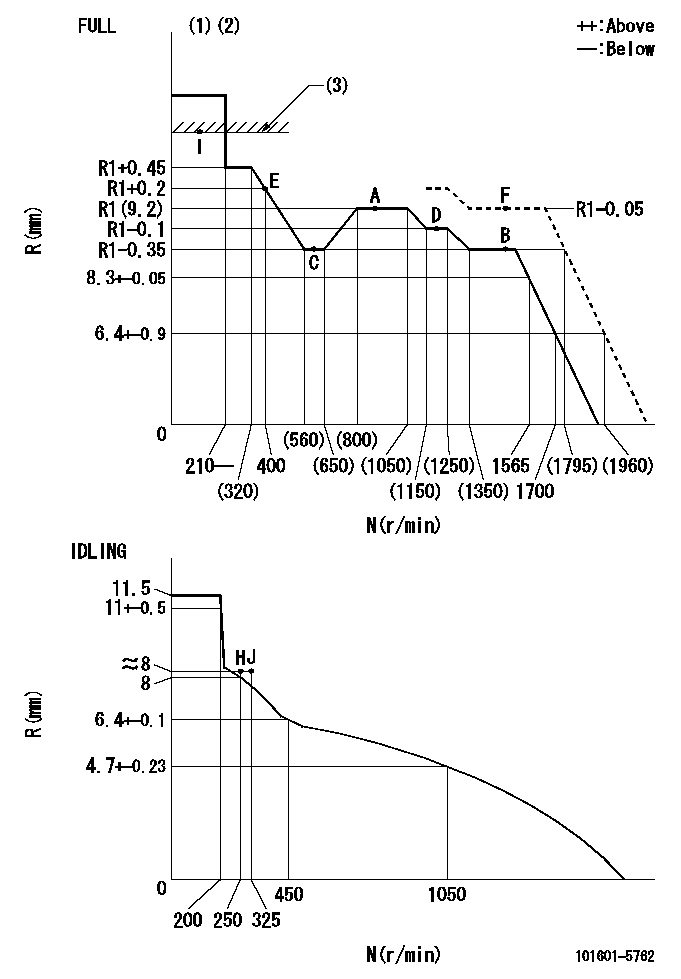

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=C09

----------

----------

T1=C09

----------

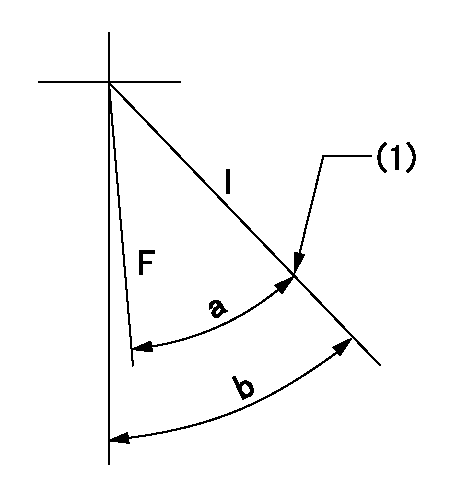

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=31deg+-3deg b=34deg+-5deg

----------

----------

a=31deg+-3deg b=34deg+-5deg

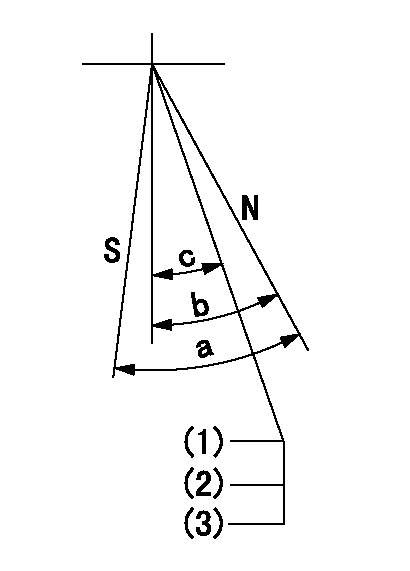

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Stopper bolt setting

(2)(Apply red paint after setting.)

(3)Engine normal

----------

----------

a=40deg+-5deg b=40deg+-5deg c=35deg+-2deg

----------

----------

a=40deg+-5deg b=40deg+-5deg c=35deg+-2deg

0000001501 TAMPER PROOF

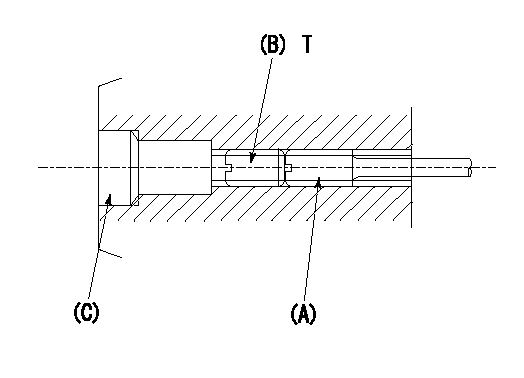

1. Method for setting tamperproof proofing

(1)Perform after governor adjustment (torque cam phase adjustment).

(2)Increase the full rack position to aa using the load lever.

(3)At N = N1, push in screw (A) until Ra.

(4)Temporarily caulk using the tip of a screwdriver

(5)Confirm that the rack at that time is Rb.

(6)Lock using setscrew (B). (Tightening torque = T)

(7)Pressfit (C) after applying adhesive.

(8)Readjust the full rack using the load lever.

----------

aa=(0.4)mm N1=1500r/min Ra=R1(9.2)-0.05mm Rb=R1(9.2)-0.05mm

----------

T=4.9~7N-m(0.5~0.7Kgf-m)

----------

aa=(0.4)mm N1=1500r/min Ra=R1(9.2)-0.05mm Rb=R1(9.2)-0.05mm

----------

T=4.9~7N-m(0.5~0.7Kgf-m)

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Adjust -to conform and correspond to specifications. Check -to observe for satisfactory conditions, accuracy, safety or performance. Exchange -to trade a worn or failing component for a remanufactured or rebuilt component. Inspect -to examine closely, in critical appraisal, while testing or evaluating components or systems. Lubricate -to apply a lubricant (oil, grease, etc.) as specified for reducing friction, heat and wear between solid surfaces. Protective Devices -indicators such as gauges, lights, emergency shutoffs, etc., that alert an operator that a potential problem may exist. Failure to respond to these indicators in a timely manner could result in engine failure. Rebuild -to repair a worn or failing component with new parts, components and/or remanufactured components. Replace -to install something new, remanufactured or rebuilt in place of an existing worn or failing component. Service Hours (Electrical) -records the time (clock hours) the engine is actually running but does not reflect variations in speed, load, etc.Interval Categories

Engine components can generally be grouped into speed sensitive and load sensitive categories. Therefore, the maintenance interval for each item listed in the Maintenance Management Schedule is primarily based on the item and its relationship to either engine speed or load. Speed sensitive items such as water pumps, air compressors, etc., are not primarily affected by the load on your engine during operation. The load on an engine will not significantly accelerate the repair or replacement cycle for speed sensitive items.Therefore, the maintenance intervals established for speed sensitive items are based on miles (kilometers) or service hours, whichever occurs first. Load sensitive items such as piston rings, cylinder liners, etc., are affected by the load on your engine during operation. Generally speaking, the lower the load, the longer the engine life and conversely, the higher the load, the shorter the engine life. A heavy load on an engine will accelerate the repair or replacement cycle for load sensitive items.Load sensitive items are normally internal engine components and the amount of fuel consumed is directly related to the load on your engine.Therefore, the maintenance interval for load sensitive items include fuel consumption, since the amount of fuel consumed is directly related to the load on your engine.Since the amount of fuel consumed is a better indicator of performing an overhaul than miles (kilometers) or service hours, Caterpillar recommends performing an overhaul on these items at the specified maintenance interval based on the quantity of fuel consumed.Interval to Overhaul

The specified overhaul interval for the 3176 Truck engine is "Every 80,000 Gallons (303 200 L) of Fuel or 500,000 Miles (805 000 km) or 10,000 Service Hours." The Maintenance Management Schedule follows. Ensure that the schedule is adhered to. PM Level means Preventive Maintenance Level.

Engine components can generally be grouped into speed sensitive and load sensitive categories. Therefore, the maintenance interval for each item listed in the Maintenance Management Schedule is primarily based on the item and its relationship to either engine speed or load. Speed sensitive items such as water pumps, air compressors, etc., are not primarily affected by the load on your engine during operation. The load on an engine will not significantly accelerate the repair or replacement cycle for speed sensitive items.Therefore, the maintenance intervals established for speed sensitive items are based on miles (kilometers) or service hours, whichever occurs first. Load sensitive items such as piston rings, cylinder liners, etc., are affected by the load on your engine during operation. Generally speaking, the lower the load, the longer the engine life and conversely, the higher the load, the shorter the engine life. A heavy load on an engine will accelerate the repair or replacement cycle for load sensitive items.Load sensitive items are normally internal engine components and the amount of fuel consumed is directly related to the load on your engine.Therefore, the maintenance interval for load sensitive items include fuel consumption, since the amount of fuel consumed is directly related to the load on your engine.Since the amount of fuel consumed is a better indicator of performing an overhaul than miles (kilometers) or service hours, Caterpillar recommends performing an overhaul on these items at the specified maintenance interval based on the quantity of fuel consumed.Interval to Overhaul

The specified overhaul interval for the 3176 Truck engine is "Every 80,000 Gallons (303 200 L) of Fuel or 500,000 Miles (805 000 km) or 10,000 Service Hours." The Maintenance Management Schedule follows. Ensure that the schedule is adhered to. PM Level means Preventive Maintenance Level.

Have questions with 101601-5762?

Group cross 101601-5762 ZEXEL

Hino

Hino

101601-5762

9 400 614 626

220007151A

INJECTION-PUMP ASSEMBLY

W06E

W06E