Information injection-pump assembly

BOSCH

9 400 611 429

9400611429

ZEXEL

101601-5682

1016015682

HINO

220006451B

220006451b

Rating:

Service parts 101601-5682 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1593A

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 611 429

9400611429

ZEXEL

101601-5682

1016015682

HINO

220006451B

220006451b

Zexel num

Bosch num

Firm num

Name

101601-5682

9 400 611 429

220006451B HINO

INJECTION-PUMP ASSEMBLY

W06E K 14BE INJECTION PUMP ASSY PE6A PE

W06E K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.07

3.13

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

9.5

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

60.2

58.2

62.2

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

8+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

6.8

5.3

8.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.5)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

60.2

59.2

61.2

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.1

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

67.3

63.3

71.3

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.45

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

37.9

33.9

41.9

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

D

Rack position

R1+0.15

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

67.8

63.8

71.8

Fixing the lever

*

Injection quantity adjustment_07

Adjusting point

E

Rack position

R1(9.5)

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

32.9

28.9

36.9

Fixing the lever

*

Injection quantity adjustment_08

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

99

99

109

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1000+50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1500

Advance angle

deg.

3.5

3.2

3.8

Remarks

Finish

Finish

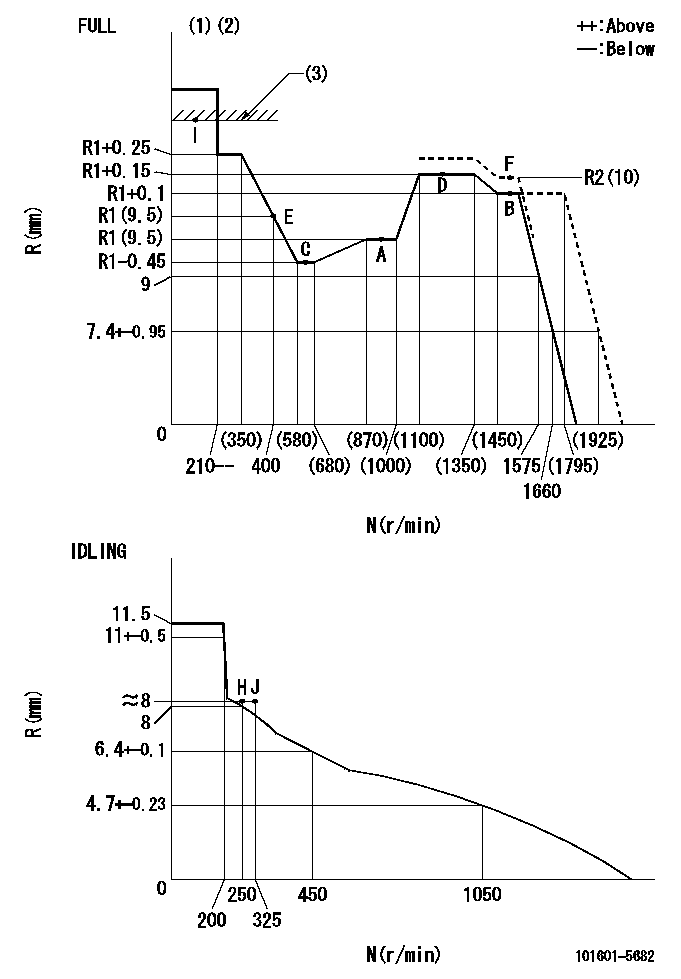

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=C10

----------

----------

T1=C10

----------

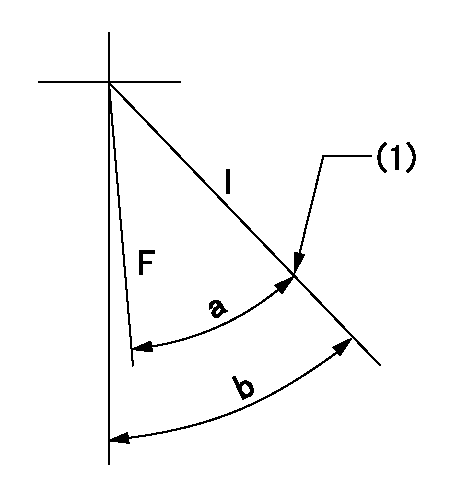

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=32deg+-3deg b=34deg+-5deg

----------

----------

a=32deg+-3deg b=34deg+-5deg

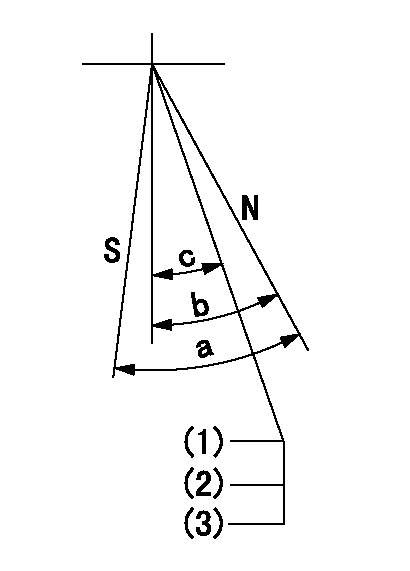

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Stopper bolt setting

(2)(Apply red paint after setting.)

(3)Engine normal

----------

----------

a=40deg+-5deg b=40deg+-5deg c=35deg+-2deg

----------

----------

a=40deg+-5deg b=40deg+-5deg c=35deg+-2deg

0000001501 TAMPER PROOF

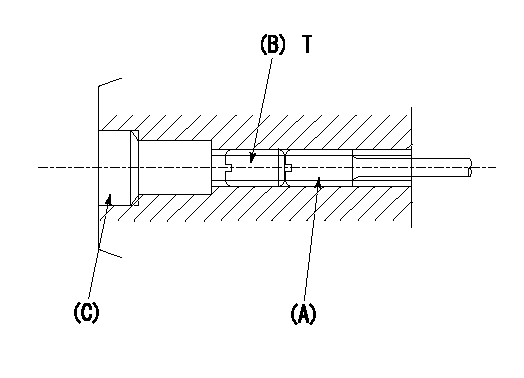

1. Method for setting tamperproof proofing

(1)After governor adjustment (torque cam phase adjustment), move the load lever to increase the full rack position to Ra.

(2)At pump speed N1, push in the screw (A) until the rack position is Rb.

(3)Temporarily caulk using the tip of a screwdriver

(4)Confirm that the rack at that time is at Rc.

(5)Lock using setscrew (B). (Tightening torque = T)

(6)Next, coat (C) with adhesive and then pressfit.

(7)Then, readjust the full rack position using the load lever.

----------

N1=1500r/min Ra=(0.4)mm Rb=R2(10)mm Rc=R2(10)mm

----------

T=4.9~7N-m(0.5~0.7Kgf-m)

----------

N1=1500r/min Ra=(0.4)mm Rb=R2(10)mm Rc=R2(10)mm

----------

T=4.9~7N-m(0.5~0.7Kgf-m)

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Engine Performance

Poor vessel performance is traditionally believed to be the result of a lack (or loss) of engine performance, when in fact the engine is only one of numerous factors that influence the overall performance of a vessel. Several factors determine the power demand on an engine. The engine has no control over the demand made upon it by the vessel design, such as hull, prop and driveline design. These same factors also affect the amount of power available to perform additional work such as to drive auxiliary pumps.If you feel you have a vessel performance problem, first consider the impact of vessel design and condition, loads, propeller and driveline condition, etc. on power demand. Deterioration of vessel systems (cooling, air intake and exhaust, fuel tanks, etc.) can only lessen the engine's chance to produce power and vessel speed. In the case of poor fuel economy, the engine is not likely to be the cause without the presence of excessive exhaust smoke and/or a significant loss of power.If you feel you have a valid engine performance problem, contact an authorized Caterpillar marine engine servicing dealer for assistance. If your engine is under warranty then the Caterpillar warranty will cover the cost of resolving a valid engine performance deficiency. However, if the engine is not found at fault, all costs incurred will be the responsibility of the owner. Adjustment of the fuel system outside Caterpillar specified limits will not improve fuel efficiency and could result in damage to the engine.Your Caterpillar dealer can determine engine condition and check the engine's external systems using a diagnostic procedure called the Marine Engine Performance Analysis Report (PAR). (See next topic).Caterpillar engines are designed and manufactured using state-of-the-art technology to provide maximum fuel efficiency and performance in all applications. To insure optimum performance for the life of your engine, follow the recommended operation and preventive maintenance procedures described in this publication.Marine Engine Performance Analysis Report (PAR)

Today's marine user is concerned with performance, cost of operation and satisfactory engine life. Traditionally, vessel performance has been directly related to the propulsion engine, when in fact the engine is only one of numerous factors influencing the propulsion system.To verify the condition of the propulsion system, Caterpillar has developed the Marine Engine Performance Analysis Report (PAR) program. Marine Engine PAR is an in-vessel test procedure, performed and evaluated by Caterpillar certified Marine Analysts under normal or bollard operating conditions, comparing the performance of all marine engine systems to original factory test cell specifications.When Marine Engine PAR testing is conducted at Sea Trial, it can assure you of a quality installation that confirms hull, rudders, propeller, marine transmission, ventilation and cooling systems are all properly matched for optimum performance and fuel efficiency.Caterpillar additionally recommends regularly scheduled (see Maintenance Schedule) Marine Engine PAR analyses to maintain optimum performance. Periodic PAR analyses can define propulsion system deterioration and aid in fine tuning the maintenance, repair and overhaul schedules, which will provide you the most economical and efficient cost of operation.

Poor vessel performance is traditionally believed to be the result of a lack (or loss) of engine performance, when in fact the engine is only one of numerous factors that influence the overall performance of a vessel. Several factors determine the power demand on an engine. The engine has no control over the demand made upon it by the vessel design, such as hull, prop and driveline design. These same factors also affect the amount of power available to perform additional work such as to drive auxiliary pumps.If you feel you have a vessel performance problem, first consider the impact of vessel design and condition, loads, propeller and driveline condition, etc. on power demand. Deterioration of vessel systems (cooling, air intake and exhaust, fuel tanks, etc.) can only lessen the engine's chance to produce power and vessel speed. In the case of poor fuel economy, the engine is not likely to be the cause without the presence of excessive exhaust smoke and/or a significant loss of power.If you feel you have a valid engine performance problem, contact an authorized Caterpillar marine engine servicing dealer for assistance. If your engine is under warranty then the Caterpillar warranty will cover the cost of resolving a valid engine performance deficiency. However, if the engine is not found at fault, all costs incurred will be the responsibility of the owner. Adjustment of the fuel system outside Caterpillar specified limits will not improve fuel efficiency and could result in damage to the engine.Your Caterpillar dealer can determine engine condition and check the engine's external systems using a diagnostic procedure called the Marine Engine Performance Analysis Report (PAR). (See next topic).Caterpillar engines are designed and manufactured using state-of-the-art technology to provide maximum fuel efficiency and performance in all applications. To insure optimum performance for the life of your engine, follow the recommended operation and preventive maintenance procedures described in this publication.Marine Engine Performance Analysis Report (PAR)

Today's marine user is concerned with performance, cost of operation and satisfactory engine life. Traditionally, vessel performance has been directly related to the propulsion engine, when in fact the engine is only one of numerous factors influencing the propulsion system.To verify the condition of the propulsion system, Caterpillar has developed the Marine Engine Performance Analysis Report (PAR) program. Marine Engine PAR is an in-vessel test procedure, performed and evaluated by Caterpillar certified Marine Analysts under normal or bollard operating conditions, comparing the performance of all marine engine systems to original factory test cell specifications.When Marine Engine PAR testing is conducted at Sea Trial, it can assure you of a quality installation that confirms hull, rudders, propeller, marine transmission, ventilation and cooling systems are all properly matched for optimum performance and fuel efficiency.Caterpillar additionally recommends regularly scheduled (see Maintenance Schedule) Marine Engine PAR analyses to maintain optimum performance. Periodic PAR analyses can define propulsion system deterioration and aid in fine tuning the maintenance, repair and overhaul schedules, which will provide you the most economical and efficient cost of operation.

Have questions with 101601-5682?

Group cross 101601-5682 ZEXEL

Hino

Hino

101601-5682

9 400 611 429

220006451B

INJECTION-PUMP ASSEMBLY

W06E

W06E