Information injection-pump assembly

ZEXEL

101601-5620

1016015620

HINO

220006411A

220006411a

Rating:

Cross reference number

ZEXEL

101601-5620

1016015620

HINO

220006411A

220006411a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8210

Nozzle

105780-0070

Bosch type code

DN12SD12T-1

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.8

3.77

3.83

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

11.5

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

77.6

76

79.2

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9+-0.5

Pump speed

r/min

250

250

250

Each cylinder's injection qty

mm3/st.

16.9

15.9

17.9

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.5)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

77.6

76.6

78.6

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.5

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

88.9

84.9

92.9

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.3

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

64.2

60.2

68.2

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

D

Rack position

R1+0.5

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

87.4

83.4

91.4

Fixing the lever

*

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

140

140

150

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

925--

Advance angle

deg.

0

0

0

Load

1/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

875

Advance angle

deg.

0.3

Load

1/4

Timer adjustment_03

Pump speed

r/min

(920--)

Advance angle

deg.

1

0.7

1.3

Load

4/4

Timer adjustment_04

Pump speed

r/min

1175+50

Advance angle

deg.

1

0.7

1.3

Load

3/4

Timer adjustment_05

Pump speed

r/min

1400+50

Advance angle

deg.

5.5

5.2

5.8

Load

4/4

Remarks

Finish

Finish

Test data Ex:

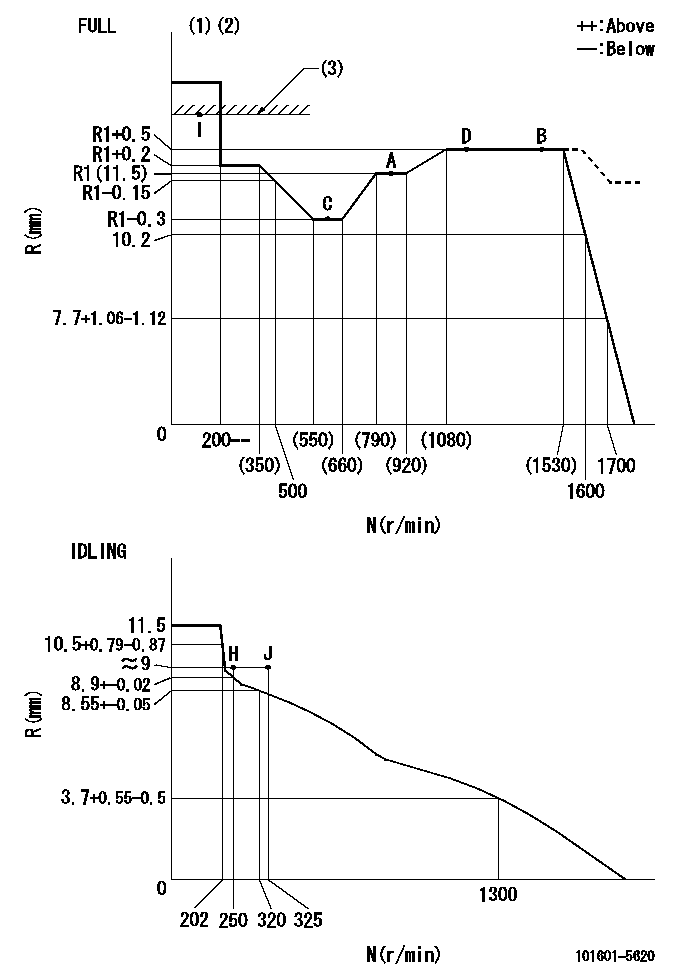

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=F80

----------

----------

T1=F80

----------

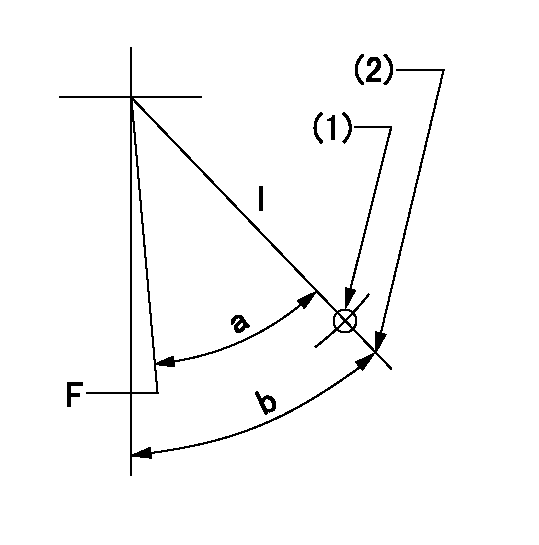

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=55mm

----------

a=37deg+-3deg b=40deg+-5deg

----------

aa=55mm

----------

a=37deg+-3deg b=40deg+-5deg

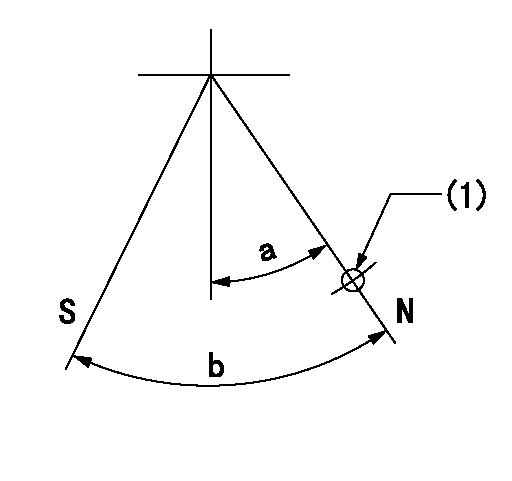

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

----------

aa=35mm

----------

a=14.5deg+-5deg b=40deg+-5deg

----------

aa=35mm

----------

a=14.5deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

The combustion process of a diesel engine produces exhaust products such as smoke (visible), hydrocarbons and oxides of nitrogen (invisible). The dark smoke emitted by a diesel engine is soot or carbon particles and even in low concentration make the diesel exhaust highly visible and offensive to most people. Every effort must be made to eliminate smoke even though it can be considered more of a nuisance than a pollutant.Under certain conditions oxides of nitrogen react with certain hydrocarbons to form smog which can become irritating and toxic if large concentrations accumulate. Concentrations of this pollutant combined with pollution of other sources all contribute to the total air quality problem.As an engine manufacturer, our goal is to see that environmental standards are met with a minimum additional complexity or cost to the product. Throughout the years, continuing research and design improvements have been directed at minimizing exhaust emissions. Caterpillar has incorporated items such as -TURBOCHARGING: Reduces exhaust noise and provides more air per cylinder allowing the fuel to burn more efficiently. These engines are integrally designed for turbocharging.AIR-FUEL RATIO CONTROL FOR TURBOCHARGED ENGINES: Limits the amount of fuel during acceleration to minimize smoke levels.RECOMMEND FUELS, LUBRICATING OILS AND MAINTENANCE SCHEDULES: To assure minimum exhaust emissions.Maintenance Recommendations

Caterpillar Truck Engines are certified by the United States Environmental Protection Agency to comply with smoke emission standard limits prescribed by Federal laws at the time of manufacture.Efficiency of emission control and good engine performance depend on adherence to proper operation and maintenance recommendations, use of recommended fuels and lubricating oils. It is recommended that major adjustments and repair be entrusted to your authorized dealer.Various chemical fuel additives are commercially available that claim to reduce visible smoke. Although additives have been used by individuals to solve some isolated smoke problems in the field, they are not recommended for general use. Federal smoke regulations require the certification of engines without a smoke depressant.The corrective steps taken immediately on discovery of worn parts, which may affect emission levels, will help assure proper operation of emission control systems. The use of genuine Caterpillar parts is recommended. Suppliers of non-Caterpillar parts must assure the user that the use of such parts will not adversely affect emission levels.Regular service intervals along with special emphasis on the following items are necessary to keep exhaust emissions within acceptable limits for the useful life of the engine. Refer to the Lubrication and Maintenance Section of this Operation Guide for details and maintenance schedule. If the engine is operating under severe conditions, adjust maintenance schedule accordingly. See your authorized dealer to help analyze your specific maintenance schedule.The following explanation of required emission related component maintenance has been keyed by number to correspond with item number in the maintenance chart.1. COOLANT - LEVEL AND PROTECTION: Check the engine coolant level daily with the engine stopped and cool. Release cooling system pressure before checking. Fill to proper level with permanent-type antifreeze and water as free as possible from scale forming minerals. DO NOT USE

Caterpillar Truck Engines are certified by the United States Environmental Protection Agency to comply with smoke emission standard limits prescribed by Federal laws at the time of manufacture.Efficiency of emission control and good engine performance depend on adherence to proper operation and maintenance recommendations, use of recommended fuels and lubricating oils. It is recommended that major adjustments and repair be entrusted to your authorized dealer.Various chemical fuel additives are commercially available that claim to reduce visible smoke. Although additives have been used by individuals to solve some isolated smoke problems in the field, they are not recommended for general use. Federal smoke regulations require the certification of engines without a smoke depressant.The corrective steps taken immediately on discovery of worn parts, which may affect emission levels, will help assure proper operation of emission control systems. The use of genuine Caterpillar parts is recommended. Suppliers of non-Caterpillar parts must assure the user that the use of such parts will not adversely affect emission levels.Regular service intervals along with special emphasis on the following items are necessary to keep exhaust emissions within acceptable limits for the useful life of the engine. Refer to the Lubrication and Maintenance Section of this Operation Guide for details and maintenance schedule. If the engine is operating under severe conditions, adjust maintenance schedule accordingly. See your authorized dealer to help analyze your specific maintenance schedule.The following explanation of required emission related component maintenance has been keyed by number to correspond with item number in the maintenance chart.1. COOLANT - LEVEL AND PROTECTION: Check the engine coolant level daily with the engine stopped and cool. Release cooling system pressure before checking. Fill to proper level with permanent-type antifreeze and water as free as possible from scale forming minerals. DO NOT USE