Information injection-pump assembly

BOSCH

9 400 614 621

9400614621

ZEXEL

101601-5591

1016015591

HINO

220006390A

220006390a

Rating:

Include in #1:

104303-2530

as _

Cross reference number

BOSCH

9 400 614 621

9400614621

ZEXEL

101601-5591

1016015591

HINO

220006390A

220006390a

Zexel num

Bosch num

Firm num

Name

101601-5591

9 400 614 621

220006390A HINO

INJECTION-PUMP ASSEMBLY

W06E K

W06E K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.07

3.13

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

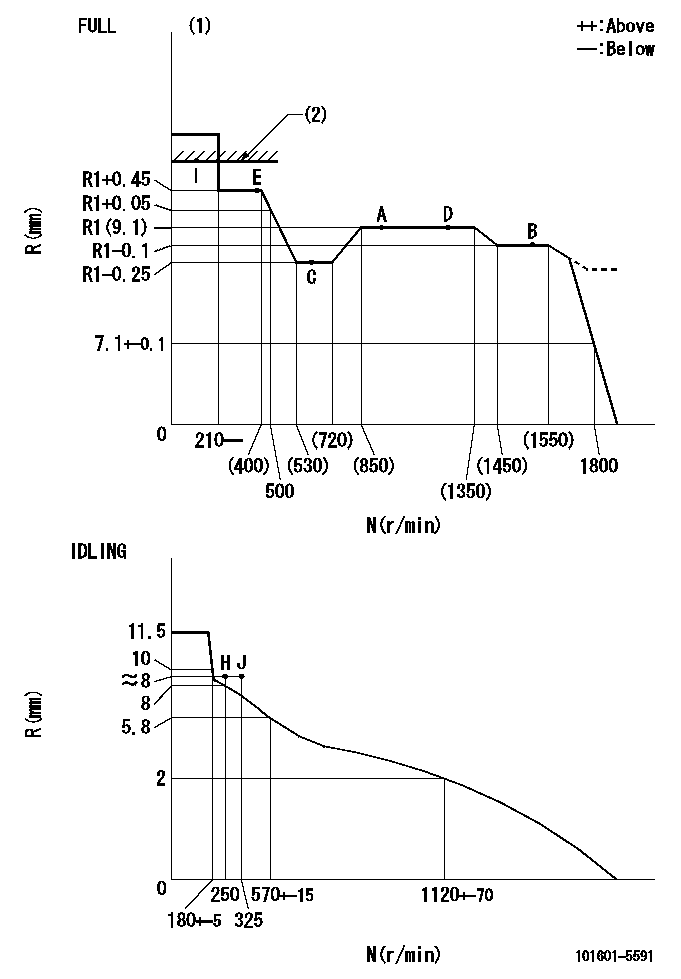

Injection quantity adjustment

Adjusting point

-

Rack position

9.1

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

48.9

46.9

50.9

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

8+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

7

5.5

8.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.1)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

48.9

47.9

49.9

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.1

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

51.3

47.3

55.3

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.25

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

35.9

31.9

39.9

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

D

Rack position

R1(9.1)

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

52.1

50.1

54.1

Fixing the lever

*

Injection quantity adjustment_07

Adjusting point

E

Rack position

(R1+0.45

)

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

31.4

27.4

35.4

Fixing the lever

*

Injection quantity adjustment_08

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

111

101

121

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1330--

Advance angle

deg.

0

0

0

Load

3/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1280

Advance angle

deg.

0.3

Load

3/4

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

4.5

4.2

4.8

Load

4/4

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=E05

----------

----------

T1=E05

----------

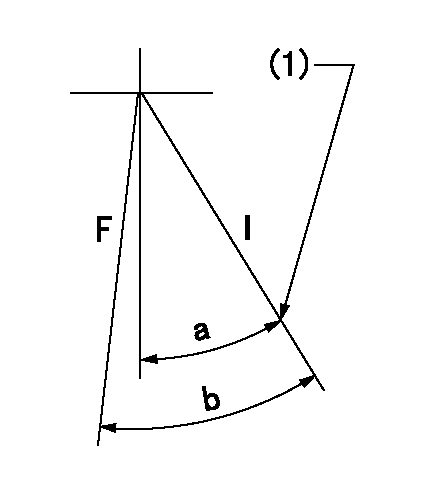

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=46deg+-5deg b=(49deg)+-3deg

----------

----------

a=46deg+-5deg b=(49deg)+-3deg

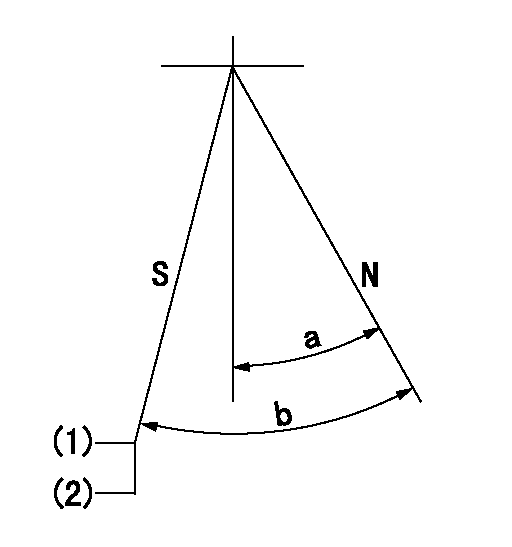

Stop lever angle

N:Engine normal (pump normal)

S:Engine stop

(1)Set the stopper screw.

(2)(Apply red paint after setting.)

----------

----------

a=20deg+-5deg b=(30.5deg)+-5deg

----------

----------

a=20deg+-5deg b=(30.5deg)+-5deg

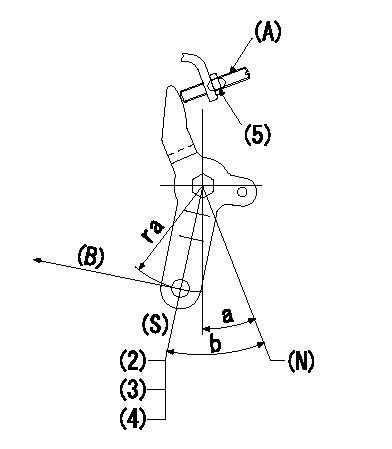

0000001501 LEVER

(N) Engine normal (pump normal)

(S) Engine stop

(A) stopper screw

(B) Stop direction (perpendicular)

Stop lever adjusting procedure

(1)After completing adjustment, confirm that the engine's normal lever angle (pump's normal lever) is within the specifications in the figure above.

(2)With the speed lever at Full and the pump speed at Na (specified speed), temporarily set the stopper screw (A) at the rack position Ra.

(3)Turn the stopper screw (A) Rb in the stop direction (Nb turns) and set it. Measure the rack position. (Rack position = approx. Rc)

(4)After setting, confirm non-injection with the speed lever at idle and pump speed at Nc.

(5)After adjustment, apply red paint.

----------

Na=1750r/min Ra=4.9mm Rb=1.5mm Nb=1.5 Rc=2.9mm Nc=250r/min

----------

ra=37mm a=20deg+-5deg b=(30.5deg)+-5deg

----------

Na=1750r/min Ra=4.9mm Rb=1.5mm Nb=1.5 Rc=2.9mm Nc=250r/min

----------

ra=37mm a=20deg+-5deg b=(30.5deg)+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

1. Engine Fails to Start2. Misfiring3. Stalls at Low Speed4. Erratic Engine Speed5. Low Power6. Excessive Vibration7. Heavy Combustion Knock8. Valve Train Clicking Knock9. Oil in Coolant10. Mechanical Knock11. Excessive Fuel Consumption12. Loud Valve Train Noise13. Excessive Valve Lash14. Valve Spring Retainer Free15. Slobber16. Valve Lash Close-up17. Premature Engine Wear18. Coolant in Engine Lubricating Oil19. Excessive Black or Grey Smoke20. Excessive White or Blue Smoke21. Low Engine Oil Pressure22. High Lubricating Oil Consumption23. Abnormal Engine Coolant Temperature24. Starting Motor Fails to Crank25. Alternator Fails to Charge26. Alternator Charging Rate Low or Unsteady27. Alternator Charging Rate High28. Alternator Noisy 1. ENGINE FAILS TO START 2. MISFIRING 3. STALLS AT LOW SPEED 4. ERRATIC ENGINE SPEED 5. LOW POWER 6. EXCESSIVE VIBRATION 7. HEAVY COMBUSTION KNOCK 8. VALVE TRAIN CLICKING NOISE 9. OIL IN COOLANT 10. MECHANICAL KNOCK 11. EXCESSIVE FUEL CONSUMPTION 12. LOUD VALVE TRAIN NOISE 13. EXCESSIVE VALVE LASH 14. VALVE SPRING RETAINER FREE 15. SLOBBER 16. VALVE LASH CLOSE-UP 17. PREMATURE ENGINE WEAR 18. COOLANT IN ENGINE LUBRICATING OIL 19. Excessive Black Or Gray Smoke 20. Excessive White Or Blue Smoke 21. Low Engine Oil Pressure 22. High Lubricating Oil Consumption 23. Abnormal Engine Coolant Temperature 24. Starting Motor Fails To Crank 25. Alternator Fails To Charge 26. Alternator Charging Rate Low Or Unsteady 27. Alternator Charging Rate High 28. Alternator Noisy *Authorized dealers are equipped with the necessary tools and personnel familiar with disassembly and assembly procedures to perform these serviced.

Have questions with 101601-5591?

Group cross 101601-5591 ZEXEL

Hino

Hino

Hino

101601-5591

9 400 614 621

220006390A

INJECTION-PUMP ASSEMBLY

W06E

W06E