Information injection-pump assembly

ZEXEL

101601-5501

1016015501

HINO

220006240A

220006240a

Rating:

Cross reference number

ZEXEL

101601-5501

1016015501

HINO

220006240A

220006240a

Zexel num

Bosch num

Firm num

Name

101601-5501

220006240A HINO

INJECTION-PUMP ASSEMBLY

W06E * K

W06E * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.07

3.13

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

9.3

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

61.9

59.9

63.9

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.4+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

9

7.5

10.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.3)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

61.9

60.9

62.9

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

R1+0.1

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

66.3

64.3

68.3

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.5

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

40.5

36.5

44.5

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

E

Rack position

R1-0.1

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

29.7

27.7

31.7

Fixing the lever

*

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

99

99

109

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1050--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1500-50

Advance angle

deg.

3.5

3

4

Remarks

Finish

Finish

Test data Ex:

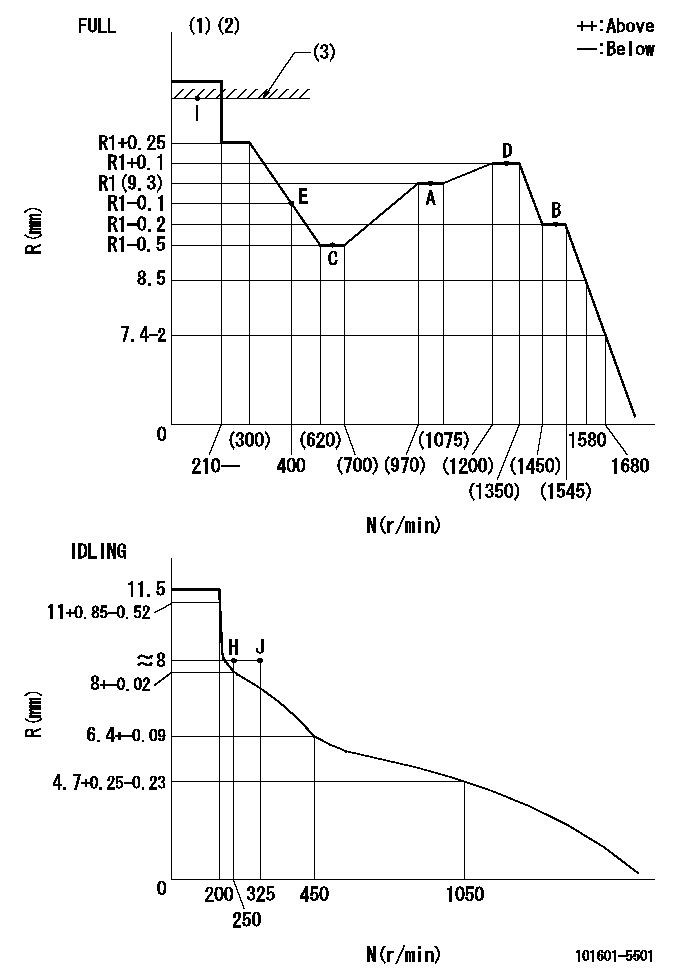

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=D84

----------

----------

T1=D84

----------

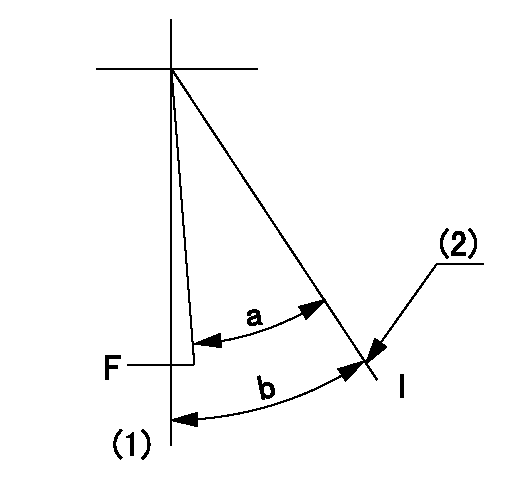

Speed control lever angle

F:Full speed

I:Idle

(1)-

(2)Stopper bolt setting

----------

----------

a=(31deg)+-3deg b=34deg+-5deg

----------

----------

a=(31deg)+-3deg b=34deg+-5deg

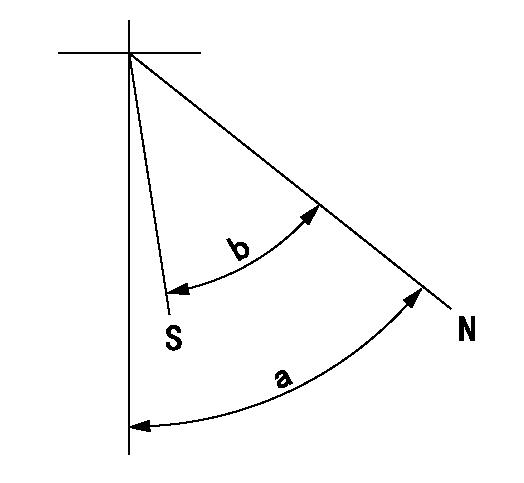

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=40deg+-5deg b=40deg+-5deg

----------

----------

a=40deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

After the engine starts, and at frequent intervals while the engine is operating, the gauges should be observed. Determine the normal reading for each gauge. Investigate the cause whenever there is a significant change in the reading.Gauges

Tachometer

The tachometer indicates engine RPM. The high idle RPM and the full load RPM are stamped on the engine's information plate. The engine can be operated between these two speed limits for long periods of time without shortening engine life. Prolonged operation at high idle with little or no load can cause adverse engine operation. Engine Oil Pressure

If the gauge reading fluctuates after the load is stable:1. Remove the load.2. Reduce engine speed to low idle.3. Observe the oil level. Maintain the oil level between the ADD and FULL mark on the dipstick. If the reading continues to fluctuate when the oil level is correct, stop engine and call your Caterpillar dealer. Engine Jacket Water Temperature

The engine should operate within the NORMAL (green) range. If the engine is operating in the (red) range and steam becomes apparent:1. Reduce the load and engine RPM.2. Inspect for coolant leaks.3. Determine if the engine must be shut down immediately; or if the engine can be safely cooled by reducing the load.See COOLING SYSTEM MAINTENANCE INSTRUCTIONS.

Do not add cold water to a hot engine: Cracking of engine components may occur. Allow the engine to cool, then add coolant.

If the temperature gauge reading registers in or near the cold range (white) while operating under load:1. Check the water temperature gauge for accuracy.2. Check the temperature regulators for proper temperature range. Replace regulators if necessary.See COOLING SYSTEM MAINTENANCE for DETAILS. Fuel pressure

If the fuel filter gauge registers in the OUT range, clean the primary fuel filter, if so equipped. Install new secondary or final fuel filter elements if gauge still registers OUT. See the FUEL MAINTENANCE INSTRUCTIONS and FUEL SPECIFICATIONS. Ammeter:

The ammeter reading is normal when the indicator is at or on the (+) side of zero, when the engine is running at rated speed. If indicator is to the left (-) side of zero, investigate and correct cause. Air Cleaner Service Indicator

When the gauge indicator locks in the red range, service the air cleaner. With the engine stopped; see AIR INDUCTION AND EXHAUST SYSTEM MAINTENANCE INSTRUCTIONS. Calibrated Gauges

Calibrated gauges are used on some engines to monitor the engine systems. If an abnormal engine condition develops, determine and analyze and correct the cause before a failure and downtime occurs.The operating limits given in the "OPERATING RANGES FOR ENGINES" chart are based on the engine running at continuous rated speed and load, after warm-up, using SAE 30, oil. If any of the gauges register at or outside the operating limits, investigate and correct any malfunction. See TROUBLESHOOTING GUIDE for guidance.

Shut the engine down if work on or around the engine is required.

DO NOT OPERATE THE ENGINE WITH THE GAUGES REGISTERING AT OR OUTSIDE THE LIMITS.

1. Tachometer.2. Left inlet manifold temperature.3. Right inlet manifold temperature.4. Left and right exhaust manifold

Tachometer

The tachometer indicates engine RPM. The high idle RPM and the full load RPM are stamped on the engine's information plate. The engine can be operated between these two speed limits for long periods of time without shortening engine life. Prolonged operation at high idle with little or no load can cause adverse engine operation. Engine Oil Pressure

If the gauge reading fluctuates after the load is stable:1. Remove the load.2. Reduce engine speed to low idle.3. Observe the oil level. Maintain the oil level between the ADD and FULL mark on the dipstick. If the reading continues to fluctuate when the oil level is correct, stop engine and call your Caterpillar dealer. Engine Jacket Water Temperature

The engine should operate within the NORMAL (green) range. If the engine is operating in the (red) range and steam becomes apparent:1. Reduce the load and engine RPM.2. Inspect for coolant leaks.3. Determine if the engine must be shut down immediately; or if the engine can be safely cooled by reducing the load.See COOLING SYSTEM MAINTENANCE INSTRUCTIONS.

Do not add cold water to a hot engine: Cracking of engine components may occur. Allow the engine to cool, then add coolant.

If the temperature gauge reading registers in or near the cold range (white) while operating under load:1. Check the water temperature gauge for accuracy.2. Check the temperature regulators for proper temperature range. Replace regulators if necessary.See COOLING SYSTEM MAINTENANCE for DETAILS. Fuel pressure

If the fuel filter gauge registers in the OUT range, clean the primary fuel filter, if so equipped. Install new secondary or final fuel filter elements if gauge still registers OUT. See the FUEL MAINTENANCE INSTRUCTIONS and FUEL SPECIFICATIONS. Ammeter:

The ammeter reading is normal when the indicator is at or on the (+) side of zero, when the engine is running at rated speed. If indicator is to the left (-) side of zero, investigate and correct cause. Air Cleaner Service Indicator

When the gauge indicator locks in the red range, service the air cleaner. With the engine stopped; see AIR INDUCTION AND EXHAUST SYSTEM MAINTENANCE INSTRUCTIONS. Calibrated Gauges

Calibrated gauges are used on some engines to monitor the engine systems. If an abnormal engine condition develops, determine and analyze and correct the cause before a failure and downtime occurs.The operating limits given in the "OPERATING RANGES FOR ENGINES" chart are based on the engine running at continuous rated speed and load, after warm-up, using SAE 30, oil. If any of the gauges register at or outside the operating limits, investigate and correct any malfunction. See TROUBLESHOOTING GUIDE for guidance.

Shut the engine down if work on or around the engine is required.

DO NOT OPERATE THE ENGINE WITH THE GAUGES REGISTERING AT OR OUTSIDE THE LIMITS.

1. Tachometer.2. Left inlet manifold temperature.3. Right inlet manifold temperature.4. Left and right exhaust manifold

Have questions with 101601-5501?

Group cross 101601-5501 ZEXEL

Hino

101601-5501

220006240A

INJECTION-PUMP ASSEMBLY

W06E

W06E