Information injection-pump assembly

ZEXEL

101601-5500

1016015500

Rating:

Cross reference number

ZEXEL

101601-5500

1016015500

Zexel num

Bosch num

Firm num

Name

101601-5500

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.07

3.13

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

9.3

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

61.9

59.9

63.9

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.4+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

9

7.5

10.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

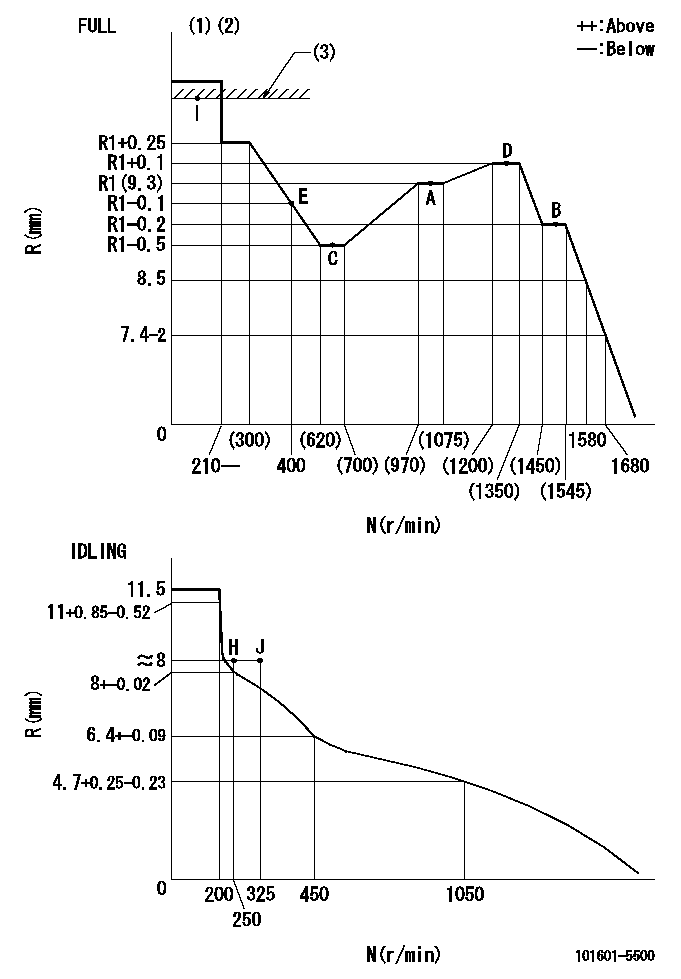

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.3)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

61.9

60.9

62.9

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

R1+0.1

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

66.3

64.3

68.3

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.5

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

40.5

38.5

42.5

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

E

Rack position

R1-0.1

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

29.7

27.7

31.7

Fixing the lever

*

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

99

99

109

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1050--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1500-50

Advance angle

deg.

3.5

3

4

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=D84

----------

----------

T1=D84

----------

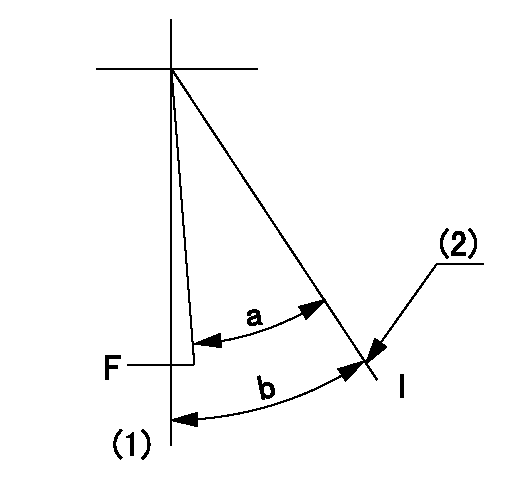

Speed control lever angle

F:Full speed

I:Idle

(1)-

(2)Stopper bolt setting

----------

----------

a=(31deg)+-3deg b=34deg+-5deg

----------

----------

a=(31deg)+-3deg b=34deg+-5deg

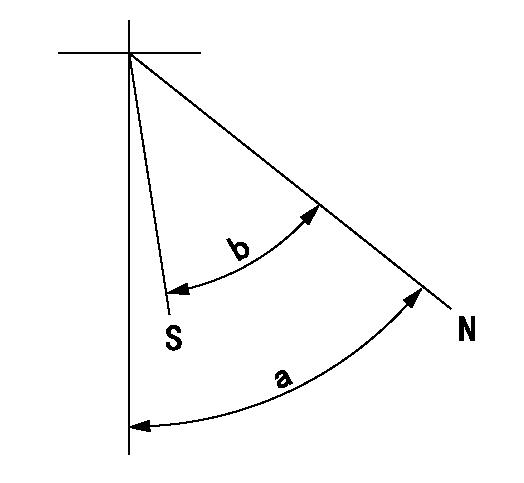

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=40deg+-5deg b=40deg+-5deg

----------

----------

a=40deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Spray starting fluid only while cranking the engine.

1. Heat the glow plugs (If equipped) for the approximate heating time shown in the STARTING AID CHART. 2. Turn the HEAT-START switch to START position. While cranking, spray starting fluid into the air inlet or air cleaner for approximately 1 second.

Wait at least 2 seconds before spraying starting fluid again.

3. If necessary, repeat the procedure.4. After the engine starts, it may be necessary to return the HEAT-START switch to the HEAT position until the engine runs smoothly.Jacket Water Heater (Attachment)

In very low temperatures, the lubricating oil must be warmed to allow starting. A jacket water heater can maintain the water temperature at approximately 90°F (32°C). The warm water will keep the oil in the upper part of the engine block warm enough to flow when starting.Dipstick Oil Heater

Contact your Caterpillar dealer before installing a dipstick crankcase oil heater.

Generator

Starting Single Unit Operation

1. Make all preliminary engine starting checks.2. Be sure the main or line circuit breaker is open.3. Start the engine and allow it to warm up.4. Close the main circuit breaker.5. Apply the load. Do not try to apply full load in one move, rather apply the load in increments to maintain system frequency at a constant level.Standby Generator Sets

Most standby units are automatic. They start, pickup the load, run and stop without an operator in attendance. Standby units can not change the governor control setting automatically. The throttle must be preset for the proper operation of that unit. Whenever the set is exercised or operated manually, be sure the throttle setting is correct for automatic operation. Check all switches to see they are properly set: Start Selector Switch in AUTOMATIC position and any Emergency Stop Switches in RUN position.Paralleling

Units may be paralleled at no load or paralleled with units under load. To parallel two or more units the following conditions must be met:1. Same phase rotation.2. Same voltage level.3. Same voltage droop.4. Same frequency.5. Voltages must be in phase.The first condition is established by "phased" wiring connections of initial installation.The second and third conditions are usually established by semi-permanent adjustments to the generator controls.The fourth and fifth conditions are under control of the operation in manual paralleling systems (or under automatic control in automatic paralleling systems).To Parallel

1. Start the unit to be paralleled.2. Turn the synchronizer lights on.3. After the engine has run long enough to warm up, bring it up to synchronous speed (the same frequency as the unit on the line). The synchronizing lights will begin to blink.4. Using the governor control, adjust the speed until the lights blink very slowly.5. The lights are off when the voltages of the two units are in phase. At this point, very quickly close the breaker while the lights are out. The frequency of the incoming unit should be slightly greater than the line frequency. This will allow the incoming unit to assume some of the load rather than add to the system load.Load Division

Once two units have been paralleled,

Have questions with 101601-5500?

Group cross 101601-5500 ZEXEL

101601-5500

INJECTION-PUMP ASSEMBLY