Information injection-pump assembly

BOSCH

9 400 614 616

9400614616

ZEXEL

101601-5492

1016015492

HINO

220006250A

220006250a

Rating:

Service parts 101601-5492 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

19.6(200)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 616

9400614616

ZEXEL

101601-5492

1016015492

HINO

220006250A

220006250a

Zexel num

Bosch num

Firm num

Name

101601-5492

9 400 614 616

220006250A HINO

INJECTION-PUMP ASSEMBLY

W06D K

W06D K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.07

3.13

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

8.7

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

46.6

44.6

48.6

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

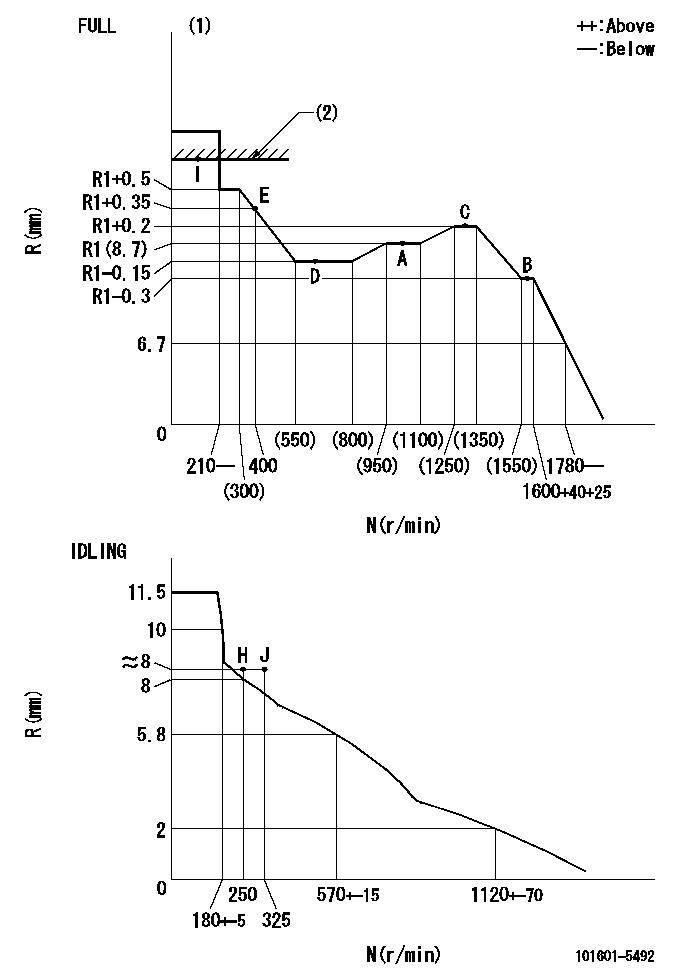

Injection quantity adjustment_02

Adjusting point

H

Rack position

8+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

8

6.5

9.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(8.7)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

46.6

45.6

47.6

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.3

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

45.2

43.2

47.2

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1+0.2

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

52

50

54

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

D

Rack position

R1-0.15

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

38

36

40

Fixing the lever

*

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

95

105

Fixing the lever

*

Rack limit

*

Injection quantity adjustment_08

Adjusting point

E

Rack position

R1+0.35

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

28

24

32

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1300+50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1600

Advance angle

deg.

3.5

3.2

3.8

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=C46

----------

----------

T1=C46

----------

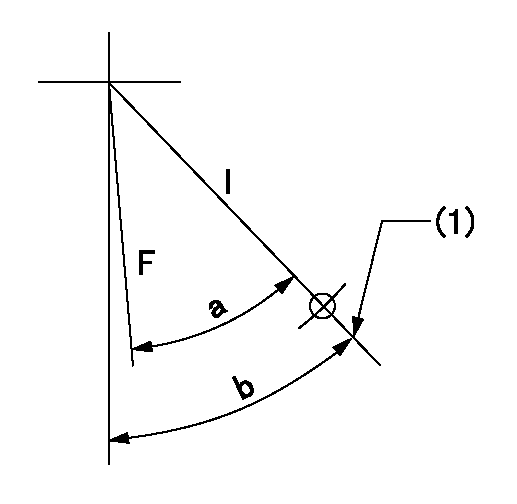

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=(45deg)+-3deg b=46deg+-5deg

----------

----------

a=(45deg)+-3deg b=46deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=20deg+-5deg b=40deg+-5deg

----------

----------

a=20deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Pre-Start Inspection And Procedures

1. Make a "walk-around" inspection of the engine and components for the oil, water or fuel leaks and general appearance. Correct minor adjustments before they develop into major repair jobs.2. Check the crankcase oil level. Maintain the oil level between the ADD and FULL marks on the dipstick. See OIL SPECIFICATIONS for type of oil to use. 3. Check oil level(s) on driven equipment.

Check the engine coolant level when the engine is cool. If the engine is warm, steam may spray outward under high pressure and cause personal injury.

4. Check the engine jacket coolant level. Slowly turn the pressure cap until the cap is removed. Maintain coolant level to the base of the fill pipe. 5. Check the fuel supply. Keep fuel tanks full, as partially filled tanks will collect moisture. See the FUEL SPECIFICATIONS for type of fuel.Keep The Fuel Supply Clean

6. Open the raw water valve on the engine jacket heat exchanger system (if so equipped). Prime the raw water pump if the raw water system has been drained.7. Reset shutoff devices. See the topic, ATTACHMENTS, Emergency Shutoff Devices and Alarms.

OIL PRESSURE RESET

OVERSPEED RESETIf the engine is equipped with an air safety shutoff control, and was tripped to the shutoff position, reset the latch to the run position.

AIR SHUTOFF RESET8. Open the fuel supply valve. If the engine has not run for some time it may be necessary to prime the system. See the topic, PRIMING THE FUEL SYSTEM.9. Disconnect any battery charger which is not protected against starting motor drain.10. Disengage the clutch, or open the circuit breaker on a generator set.

1. Make a "walk-around" inspection of the engine and components for the oil, water or fuel leaks and general appearance. Correct minor adjustments before they develop into major repair jobs.2. Check the crankcase oil level. Maintain the oil level between the ADD and FULL marks on the dipstick. See OIL SPECIFICATIONS for type of oil to use. 3. Check oil level(s) on driven equipment.

Check the engine coolant level when the engine is cool. If the engine is warm, steam may spray outward under high pressure and cause personal injury.

4. Check the engine jacket coolant level. Slowly turn the pressure cap until the cap is removed. Maintain coolant level to the base of the fill pipe. 5. Check the fuel supply. Keep fuel tanks full, as partially filled tanks will collect moisture. See the FUEL SPECIFICATIONS for type of fuel.Keep The Fuel Supply Clean

6. Open the raw water valve on the engine jacket heat exchanger system (if so equipped). Prime the raw water pump if the raw water system has been drained.7. Reset shutoff devices. See the topic, ATTACHMENTS, Emergency Shutoff Devices and Alarms.

OIL PRESSURE RESET

OVERSPEED RESETIf the engine is equipped with an air safety shutoff control, and was tripped to the shutoff position, reset the latch to the run position.

AIR SHUTOFF RESET8. Open the fuel supply valve. If the engine has not run for some time it may be necessary to prime the system. See the topic, PRIMING THE FUEL SYSTEM.9. Disconnect any battery charger which is not protected against starting motor drain.10. Disengage the clutch, or open the circuit breaker on a generator set.

Have questions with 101601-5492?

Group cross 101601-5492 ZEXEL

Hino

Hino

Hino

Hino

Hino

Hino

101601-5492

9 400 614 616

220006250A

INJECTION-PUMP ASSEMBLY

W06D

W06D