Information injection-pump assembly

BOSCH

9 400 614 615

9400614615

ZEXEL

101601-5486

1016015486

HINO

220006232A

220006232a

Rating:

Service parts 101601-5486 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

19.6(200)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 615

9400614615

ZEXEL

101601-5486

1016015486

HINO

220006232A

220006232a

Zexel num

Bosch num

Firm num

Name

101601-5486

9 400 614 615

220006232A HINO

INJECTION-PUMP ASSEMBLY

W06E-E * K

W06E-E * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.45

3.42

3.48

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

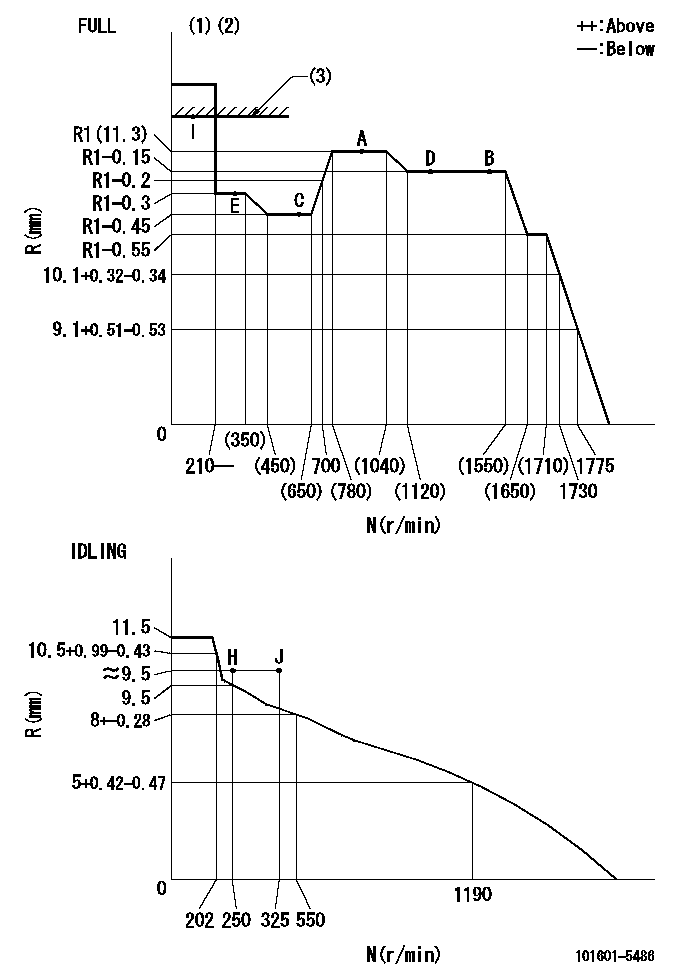

Adjusting point

-

Rack position

11.3

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

66.5

64.5

68.5

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

250

250

250

Each cylinder's injection qty

mm3/st.

16.4

15.4

17.4

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.3)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

66.5

65.5

67.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.15

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

63

59

67

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.45

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

46.8

42.8

50.8

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

124

124

134

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

960--

Advance angle

deg.

0

0

0

Load

1/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

910

Advance angle

deg.

0.3

Load

1/4

Timer adjustment_03

Pump speed

r/min

1010

Advance angle

deg.

1

0.7

1.3

Load

4/4

Timer adjustment_04

Pump speed

r/min

1210

Advance angle

deg.

1

0.7

1.3

Load

3/4

Timer adjustment_05

Pump speed

r/min

1510

Advance angle

deg.

6

5.7

6.3

Load

4/4

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=H53

----------

----------

T1=H53

----------

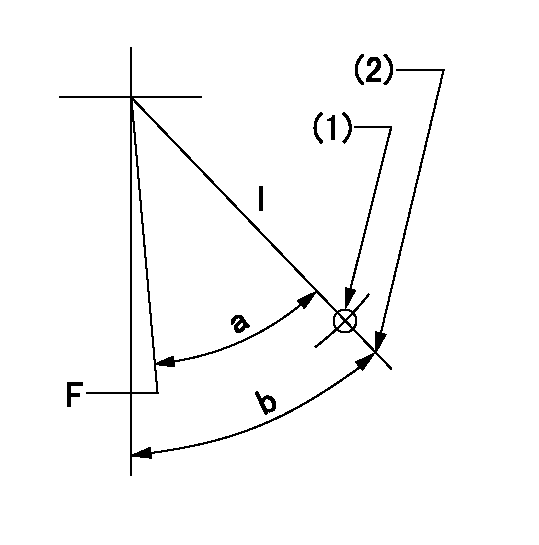

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=50mm

----------

a=(41deg)+-3deg b=46deg+-5deg

----------

aa=50mm

----------

a=(41deg)+-3deg b=46deg+-5deg

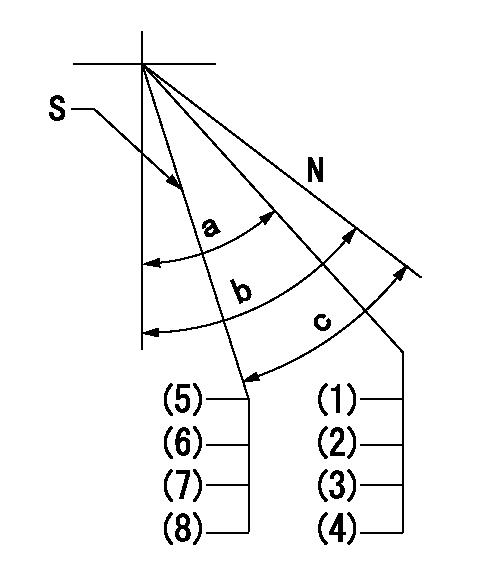

Stop lever angle

N:Pump normal

S:Engine stop

(1)Engine normal

(2)Rack position = aa

(3)Set the stopper bolt (at shipping).

(4)(Apply red paint after setting.)

(5)At speed lever full position and pump speed bb, set the stopper screw at rack position cc (non-injection rack position).

(6)Then confirm non-injection at speed lever idle speed = dd.

(7)Set the idle speed at ee using the speed lever and move the stop lever 2 or 3 turns. Confirm that the rack is not pulled back.

(8)After adjustment, apply red paint.

----------

aa=15+-0.1mm bb=1500r/min cc=6.6-0.5mm dd=250r/min ee=0r/min

----------

a=(35deg) b=40deg+-5deg c=26deg+-5deg

----------

aa=15+-0.1mm bb=1500r/min cc=6.6-0.5mm dd=250r/min ee=0r/min

----------

a=(35deg) b=40deg+-5deg c=26deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

This guide contains operation instructions and lubrication and maintenance information.The operation section is a reference for the new operator and a refresher for the experienced one. Read - study - and keep it handy.Illustrations guide the operator through correct procedures of checking, starting, operating and stopping the engine.The maintenance section is a guide to equipment care. The illustrated, step-by-step instructions are grouped by servicing intervals. Items in the "Lubrication and Maintenance Chart" are referenced to the detailed instructions that follow.Use the service meter to determine servicing intervals. Calendar intervals shown may be used instead of service meter intervals if they provide more convenient servicing schedules and approximate the indicated service meter reading. Recommended service should always be performed at the interval that occurs first.Under extremely severe, dusty or wet operating conditions, more frequent lubrication than is specified in the "Lubrication and Maintenance Chart" may be necessary.Perform service on items at multiples of the original requirement. For example, at Every 500 Service Meter Units, also service those items listed under Every 250 Service Meter Units, Every 50 Service Meter Units and Every 10 Service Meter Units.Some photographs in this publication show details or attachments that may be different from your engine. Also, guards and covers may have been removed for illustrative purposes.Continuing improvement and advancement of product design may have caused changes to your engine which are not included in this publication.Each publication is reviewed and revised, as required, to update and include these changes in later editions.Whenever a question arises regarding your engine or this publication, please consult your Caterpillar dealer for the latest available information.Engine Identification

Caterpillar engines are identified with SERIAL NUMBERS and ARRANGEMENT NUMBERS. In some cases MODIFICATION NUMBERS are also used. These numbers are shown on the serial number plate mounted on the engine.Caterpillar dealers need all of these numbers to determine which components were included on the engine when it was assembled at the factory. This permits accurate identification of replacement part numbers.Ordering Parts

Quality Caterpillar replacement parts are available from Caterpillar dealers throughout the world. Their parts stocks are up to date and include all parts normally required to protect your investment in Caterpillar engines. When ordering parts, your order should specify the quantity, part number, part name and serial number, arrangement number and modification number of the engine for which the parts are needed. If in doubt about the part number, please provide your dealer with a complete description of the needed item.

Caterpillar engines are identified with SERIAL NUMBERS and ARRANGEMENT NUMBERS. In some cases MODIFICATION NUMBERS are also used. These numbers are shown on the serial number plate mounted on the engine.Caterpillar dealers need all of these numbers to determine which components were included on the engine when it was assembled at the factory. This permits accurate identification of replacement part numbers.Ordering Parts

Quality Caterpillar replacement parts are available from Caterpillar dealers throughout the world. Their parts stocks are up to date and include all parts normally required to protect your investment in Caterpillar engines. When ordering parts, your order should specify the quantity, part number, part name and serial number, arrangement number and modification number of the engine for which the parts are needed. If in doubt about the part number, please provide your dealer with a complete description of the needed item.

Have questions with 101601-5486?

Group cross 101601-5486 ZEXEL

Hino

Hino

Hino

Hino

Hino

101601-5486

9 400 614 615

220006232A

INJECTION-PUMP ASSEMBLY

W06E-E

W06E-E