Information injection-pump assembly

ZEXEL

101601-5400

1016015400

Rating:

Service parts 101601-5400 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2412E

12.

Open Pre:MPa(Kqf/cm2)

16.7{170}/23.5{240}

14.

NOZZLE

Cross reference number

ZEXEL

101601-5400

1016015400

Zexel num

Bosch num

Firm num

Name

101601-5400

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.07

3.13

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

9.4

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

70

69

71

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7+-0.1

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

8

7

9

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.4)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

70

69

71

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

140

140

150

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1250--

Advance angle

deg.

0

0

0

Load

3/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

0.3

Load

3/4

Timer adjustment_03

Pump speed

r/min

1450

Advance angle

deg.

4

3.5

4.5

Load

4/4

Remarks

Finish

Finish

Test data Ex:

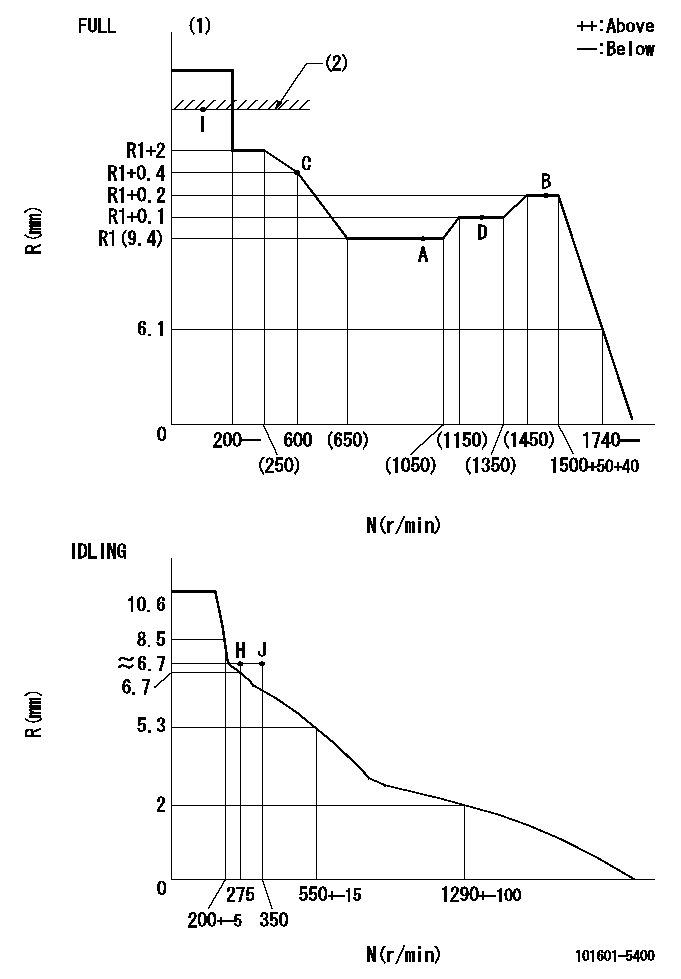

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=B94

----------

----------

T1=B94

----------

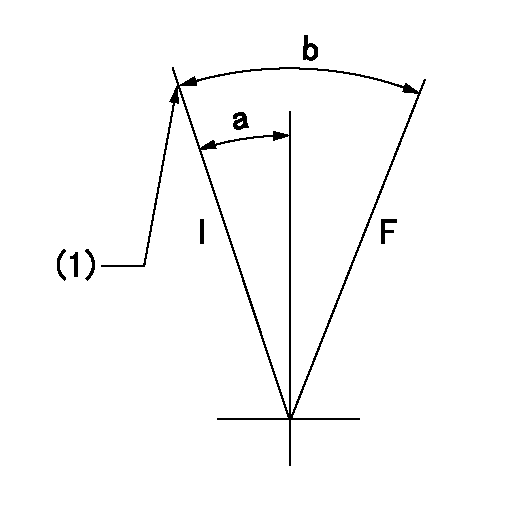

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=23deg+-5deg b=(45deg)+-3deg

----------

----------

a=23deg+-5deg b=(45deg)+-3deg

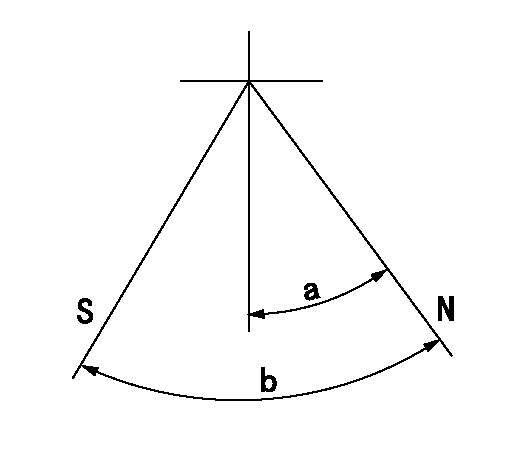

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=14.5deg+-5deg b=40deg+-5deg

----------

----------

a=14.5deg+-5deg b=40deg+-5deg

0000001501 AIR CYLINDER

(A): Speed lever

(B): Set bolt

(C): air cylinder

(D): nut

(E): fix

1. Air cylinder adjustment procedure

(1)With the speed lever in the idling position, temporarily set the clearance between speed lever (A) and set bolt (B) at approximately L1.

(2)Set the speed to N1 and supply positive pressure P1 to the air cylinder (C).

(3)Gradually push set bolt (B) out (approximately L2) and tighten nut (D) where the speed is N2 and the rack position is Ra.

(4)Apply positive pressure P1 several times.

(5)Confirm that the lever returns to the idle position at positive pressure P2.

(6)Also, confirm that the rack position is Rb at air pressure P1.

----------

L1=5mm L2=2mm Ra=6.9+-0.1mm Rb=6.9+-0.1mm N1=450r/min N2=450r/min P1=392+98kPa(4+1kgf/cm2) P2=0kPa(0kgf/cm2)

----------

----------

L1=5mm L2=2mm Ra=6.9+-0.1mm Rb=6.9+-0.1mm N1=450r/min N2=450r/min P1=392+98kPa(4+1kgf/cm2) P2=0kPa(0kgf/cm2)

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Start By:a. disassemble governorb. remove fuel injection pumps 1. Remove rack (1) from the fuel pump housing. 2. Remove six lifters (2) from the fuel pump housing. Put identification marks on the lifters for installation purposes. 3. Remove camshaft (3) from the fuel pump housing. It may be necessary to use a soft hammer to push the camshaft out of the governor end of the fuel pump housing. 4. Remove races (4) and bearing (5) from the camshaft. Remove ring (6) if necessary. 5. Remove rack bearing (7) from both ends of the housing and dowel (8) if necessary. 6. Use tooling (A), and remove three camshaft bearings (9). 7. Remove the bolts, cover (10) and the gasket. 8. Remove pins (12), the seal and dowels (11) if necessary. Pins (12) must be pushed from the inside out.Assemble Fuel Injection Pump Housing

1. Clean and inspect all parts. Make a replacement of all parts that are worn or damaged. 2. Lubricate the seal with clean engine oil, and install pin (1). Pin (1) must protrude into the pump bore 2.15 .05 mm (.085 .002 in).3. Install dowel (2) so that it protrudes into the pump bore 1.93 0.05 mm (.076 .002 in). 4. Install the gasket, cover (3) and the bolts. 5. Install the rack bearing with tooling (A). Install the bearing until the driver comes in contact with the plate. The bearing should be installed to a depth of 83.0 0.5 mm (3.27 .02 in) from the fuel pump mounting face. 6. Measure rack bearing (4). Dimension (X) must be 11.178 0.05 mm (.4400 .002 in). Diameter (W) must be 12.767 0.058 mm (.5026 .0022 in). 7. Install dowel (5). Dowel (5) must protrude 6.0 0.5 mm (.24 .02 in) from the fuel pump housing face.8. Install the rear rack bearing with tooling (B) to a depth of 7.16 0.13 mm (.282 .005 in) below the fuel pump housing surface. The inside diameter of the rear rack bearing must be 12.746 0.045 mm (.5018 .0017 in). 9. Use tooling (C), and install three camshaft bearings (6). Oil holes (7) in the camshaft bearings must be positioned 30° 3° above the horizontal centerline toward the engine side of the fuel pump housing. The outer bearings must be installed 1.0 0.5 mm (0.04 0.02 in) below the surface marked (Z). The inner bearing must be installed 218.0 0.3 mm (8.58 .012 in) below the front surface (Y). Diameter (XX) must be 68.339 0.038 mm (2.6905 .0015 in) after assembly. 10. Install ring (8), races (10) and bearing (9) on the camshaft. 11. Lubricate cam bearings (6) and the camshaft bearing journals with clean engine oil.12. Install camshaft (11) into the fuel pump housing.

The notch in the lifter must be in line with the dowel in the lifter bore. The lifter must slide up and down freely in

1. Clean and inspect all parts. Make a replacement of all parts that are worn or damaged. 2. Lubricate the seal with clean engine oil, and install pin (1). Pin (1) must protrude into the pump bore 2.15 .05 mm (.085 .002 in).3. Install dowel (2) so that it protrudes into the pump bore 1.93 0.05 mm (.076 .002 in). 4. Install the gasket, cover (3) and the bolts. 5. Install the rack bearing with tooling (A). Install the bearing until the driver comes in contact with the plate. The bearing should be installed to a depth of 83.0 0.5 mm (3.27 .02 in) from the fuel pump mounting face. 6. Measure rack bearing (4). Dimension (X) must be 11.178 0.05 mm (.4400 .002 in). Diameter (W) must be 12.767 0.058 mm (.5026 .0022 in). 7. Install dowel (5). Dowel (5) must protrude 6.0 0.5 mm (.24 .02 in) from the fuel pump housing face.8. Install the rear rack bearing with tooling (B) to a depth of 7.16 0.13 mm (.282 .005 in) below the fuel pump housing surface. The inside diameter of the rear rack bearing must be 12.746 0.045 mm (.5018 .0017 in). 9. Use tooling (C), and install three camshaft bearings (6). Oil holes (7) in the camshaft bearings must be positioned 30° 3° above the horizontal centerline toward the engine side of the fuel pump housing. The outer bearings must be installed 1.0 0.5 mm (0.04 0.02 in) below the surface marked (Z). The inner bearing must be installed 218.0 0.3 mm (8.58 .012 in) below the front surface (Y). Diameter (XX) must be 68.339 0.038 mm (2.6905 .0015 in) after assembly. 10. Install ring (8), races (10) and bearing (9) on the camshaft. 11. Lubricate cam bearings (6) and the camshaft bearing journals with clean engine oil.12. Install camshaft (11) into the fuel pump housing.

The notch in the lifter must be in line with the dowel in the lifter bore. The lifter must slide up and down freely in

Have questions with 101601-5400?

Group cross 101601-5400 ZEXEL

101601-5400

INJECTION-PUMP ASSEMBLY