Information injection-pump assembly

BOSCH

9 400 614 608

9400614608

ZEXEL

101601-5301

1016015301

HINO

220005680A

220005680a

Rating:

Service parts 101601-5301 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 608

9400614608

ZEXEL

101601-5301

1016015301

HINO

220005680A

220005680a

Zexel num

Bosch num

Firm num

Name

101601-5301

9 400 614 608

220005680A HINO

INJECTION-PUMP ASSEMBLY

W06D K

W06D K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.07

3.13

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

8.7

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

46.6

44.6

48.6

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

8+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

8

6.5

9.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(8.7)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

46.6

45.6

47.6

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.3

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

45.2

43.2

47.2

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1+0.2

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

52

50

54

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

D

Rack position

R1-0.15

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

38

36

40

Fixing the lever

*

Injection quantity adjustment_07

Adjusting point

I

Rack position

13.5+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

95

105

Fixing the lever

*

Rack limit

*

Injection quantity adjustment_08

Adjusting point

E

Rack position

R1+0.35

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

28

24

32

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1300+50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1600

Advance angle

deg.

3.5

3.2

3.8

Remarks

Finish

Finish

Test data Ex:

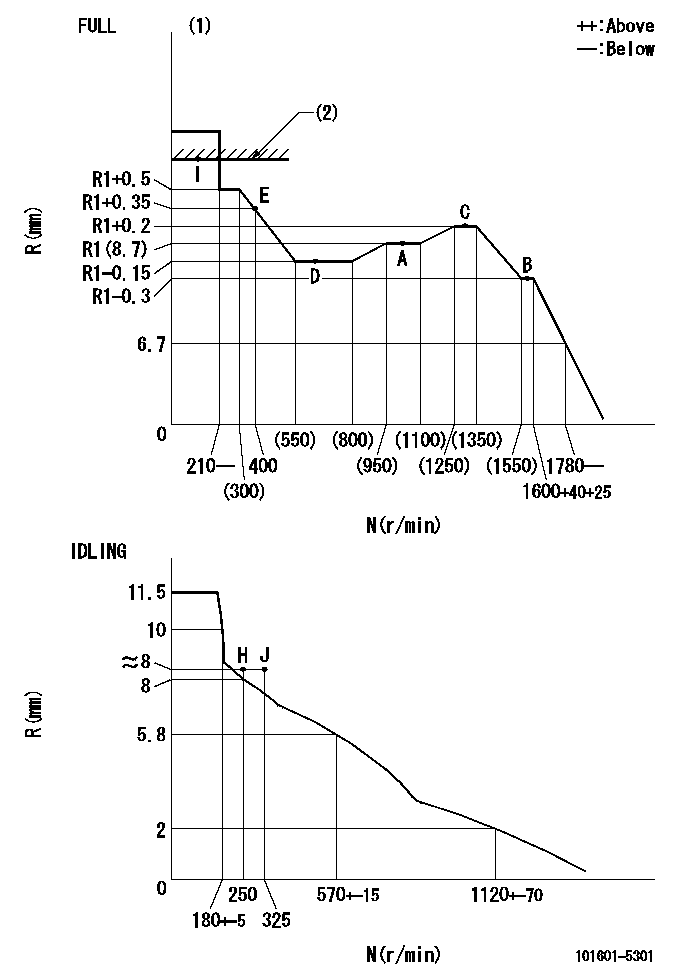

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=C46

----------

----------

T1=C46

----------

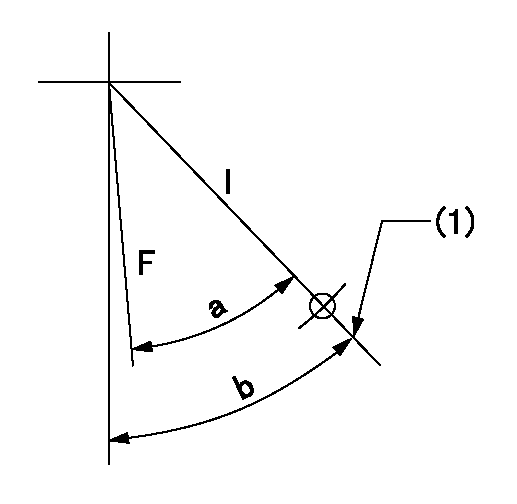

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=(45deg)+-3deg b=46deg+-5deg

----------

----------

a=(45deg)+-3deg b=46deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=20deg+-5deg b=40deg+-5deg

----------

----------

a=20deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

The Primary Engine Checks consist of quick and easy procedures that could identify the problem with a minimum loss of time. Always make these checks before starting the more involved troubleshooting procedures.Whenever a problem is found and corrected, always run the test again to that point to be sure there is not a combination of problems. When the problem has been corrected and the complaint resolved, stop the test. Do not continue through the complete procedure unless it is necessary.Possible Causes/Corrections

Prestart Checks

Make sure the air filter elements are in good condition and are not plugged. Also, make sure the engine oil and coolant are at the correct levels.Check Accelerator Linkage

To check the linkage adjustment, push the pedal down until it hits the stop. If the linkage adjustment is correct, the governor linkage will move to the break-over position when the pedal is against the stop. This is shown by clearance on both sides of the tang (see the illustration). When there is clearance on both sides of the tang, the governor linkage is adjusted correctly to permit the engine to operate at high idle. If clearance is not present on both sides of the tang, adjust the governor linkage to give the needed clearance.

Governor Control Linkage Adjustment

(1) Clearance on both sides of tang. (2) Governor control linkage. (3) Pedal (full travel). (4) Governor control. (5) Lever assembly.Check Vehicle Tachometer

Install the 6V3121 Multitach Group. Start the engine and make sure that the vehicle tachometer is accurately indicating engine rpm. Some electric vehicle tachometers can be adjusted. Correct the tachometer as required. A defective tachometer can cause operation at the wrong engine rpm, this can give the feel of low power.Check For Air In The Fuel

Disconnect the fuel return line. With the engine in operation, let the fuel from the injection pump housing flow into a container. Look for air bubbles in the fuel coming from the return line. Approximately 5 to 100 visible air bubbles in the fuel is normal. If there is excessive air in the fuel find the cause and correct it. Such as checking all fuel lines and connections for leaks and repair or replacement of parts as needed.Check Fuel API Gravity Rating

Caterpillar diesel engines are set in production to produce rated power with a fuel of 35 API gravity (0.85 specific gravity). This limit provides a grade of fuel that aids engine starting and avoids vapor lock. Fuel with higher API gravities (i.e., lower specific gravities), will produce less horsepower at the factory power setting and vice versa for lower than 35 API gravity fuels. The engine fuel setting should not be adjusted to compensate for a power loss with fuels lighter than 35 as fuel system component life may be decreased.For more information see Special Instruction Form No. SEHS7067, Fuel Recommendations For Caterpillar Diesel Engines. Also, Special Instruction, Form No. SEHS6947 has fuel correction factors and tables.Check For Proper Fuel Heater Application

Make sure that fuel heaters are correctly used. In some cold climates, fuel

Prestart Checks

Make sure the air filter elements are in good condition and are not plugged. Also, make sure the engine oil and coolant are at the correct levels.Check Accelerator Linkage

To check the linkage adjustment, push the pedal down until it hits the stop. If the linkage adjustment is correct, the governor linkage will move to the break-over position when the pedal is against the stop. This is shown by clearance on both sides of the tang (see the illustration). When there is clearance on both sides of the tang, the governor linkage is adjusted correctly to permit the engine to operate at high idle. If clearance is not present on both sides of the tang, adjust the governor linkage to give the needed clearance.

Governor Control Linkage Adjustment

(1) Clearance on both sides of tang. (2) Governor control linkage. (3) Pedal (full travel). (4) Governor control. (5) Lever assembly.Check Vehicle Tachometer

Install the 6V3121 Multitach Group. Start the engine and make sure that the vehicle tachometer is accurately indicating engine rpm. Some electric vehicle tachometers can be adjusted. Correct the tachometer as required. A defective tachometer can cause operation at the wrong engine rpm, this can give the feel of low power.Check For Air In The Fuel

Disconnect the fuel return line. With the engine in operation, let the fuel from the injection pump housing flow into a container. Look for air bubbles in the fuel coming from the return line. Approximately 5 to 100 visible air bubbles in the fuel is normal. If there is excessive air in the fuel find the cause and correct it. Such as checking all fuel lines and connections for leaks and repair or replacement of parts as needed.Check Fuel API Gravity Rating

Caterpillar diesel engines are set in production to produce rated power with a fuel of 35 API gravity (0.85 specific gravity). This limit provides a grade of fuel that aids engine starting and avoids vapor lock. Fuel with higher API gravities (i.e., lower specific gravities), will produce less horsepower at the factory power setting and vice versa for lower than 35 API gravity fuels. The engine fuel setting should not be adjusted to compensate for a power loss with fuels lighter than 35 as fuel system component life may be decreased.For more information see Special Instruction Form No. SEHS7067, Fuel Recommendations For Caterpillar Diesel Engines. Also, Special Instruction, Form No. SEHS6947 has fuel correction factors and tables.Check For Proper Fuel Heater Application

Make sure that fuel heaters are correctly used. In some cold climates, fuel

Have questions with 101601-5301?

Group cross 101601-5301 ZEXEL

Hino

101601-5301

9 400 614 608

220005680A

INJECTION-PUMP ASSEMBLY

W06D

W06D