Information injection-pump assembly

ZEXEL

101601-5233

1016015233

HINO

220005332A

220005332a

Rating:

Service parts 101601-5233 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

236001840A

12.

Open Pre:MPa(Kqf/cm2)

14.7(150)/19.6(200)

15.

NOZZLE SET

Cross reference number

ZEXEL

101601-5233

1016015233

HINO

220005332A

220005332a

Zexel num

Bosch num

Firm num

Name

101601-5233

220005332A HINO

INJECTION-PUMP ASSEMBLY

W06E * K

W06E * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.07

3.13

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

9.6

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

57.9

55.9

59.9

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

7.8+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

5.3

3.8

6.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.6)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

57.9

56.9

58.9

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(9.6)

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

63.9

59.9

67.9

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.25

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

40.3

36.3

44.3

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

D

Rack position

R1(9.6)

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

63.7

59.7

67.7

Fixing the lever

*

Injection quantity adjustment_07

Adjusting point

E

Rack position

R1+0.45

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

39.9

35.9

43.9

Fixing the lever

*

Injection quantity adjustment_08

Adjusting point

I

Rack position

14.5+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

108

108

118

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1330--

Advance angle

deg.

0

0

0

Load

3/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1280

Advance angle

deg.

0.3

Load

3/4

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

4.5

4.2

4.8

Load

4/4

Remarks

Finish

Finish

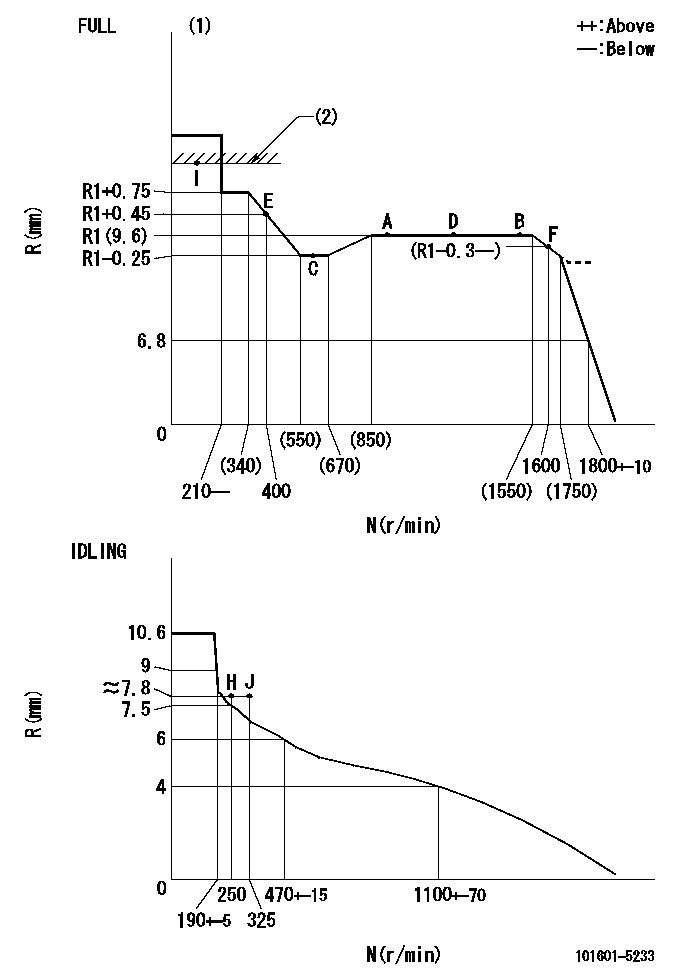

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=C02

----------

----------

T1=C02

----------

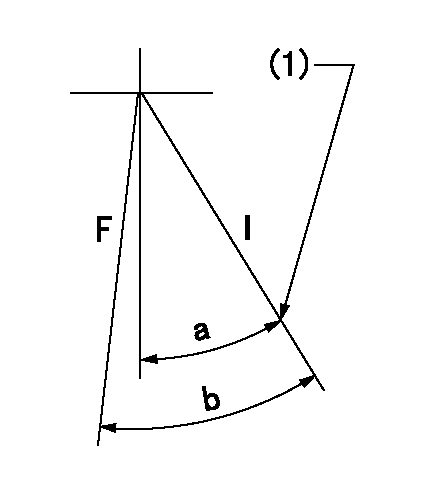

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=37deg+-5deg b=44deg+-3deg

----------

----------

a=37deg+-5deg b=44deg+-3deg

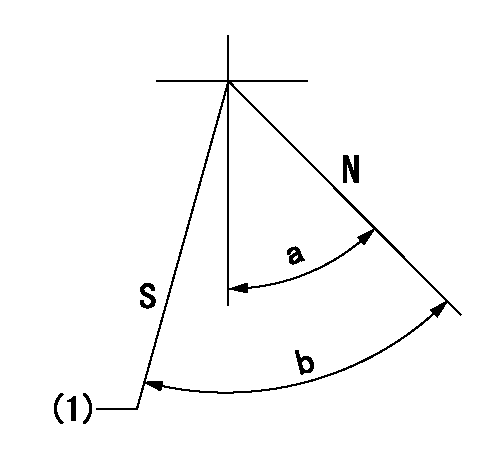

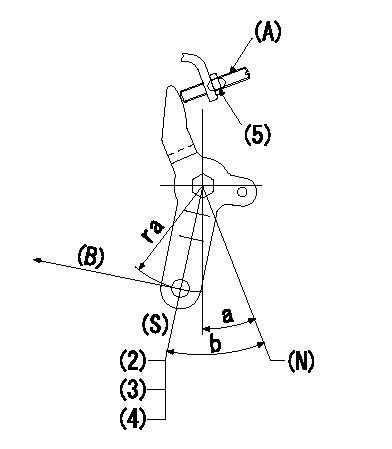

Stop lever angle

N:Engine normal (pump normal)

S:Engine stop

(1)Set the stopper screw. (After setting, apply red paint.)

----------

----------

a=20deg+-5deg b=(28deg)+-5deg

----------

----------

a=20deg+-5deg b=(28deg)+-5deg

0000001501 LEVER

(N) Engine normal (pump normal)

(S) Engine stop

(A) stopper screw

(B) Stop direction (perpendicular)

Stop lever adjusting procedure

(1)After completing adjustment, confirm that the engine's normal lever angle (pump's normal lever) is within the specifications in the figure above.

(2)With the speed lever at Full and the pump speed at Na (specified speed), temporarily set the stopper screw (A) at the rack position Ra.

(3)Turn the stopper screw (A) Rb in the stop direction (Nb turns) and set it. Measure the rack position. (Rack position = approx. Rc)

(4)After setting, confirm non-injection with the speed lever at idle and pump speed at Nc.

(5)After adjustment, apply red paint.

----------

Na=1750r/min Ra=5.2mm Rb=1.5mm Nb=1.5 Rc=3.2mm Nc=250r/min

----------

ra=37mm a=20deg+-5deg b=(28deg)+-5deg

----------

Na=1750r/min Ra=5.2mm Rb=1.5mm Nb=1.5 Rc=3.2mm Nc=250r/min

----------

ra=37mm a=20deg+-5deg b=(28deg)+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

(1) Thickness of spacer plate ... 8.585 0.025 mm (.3379 .0009 in)Thickness of gasket that is placed between spacer plate and cylinder block ... 0.208 0.025 mm (.0081 .0009 in)Height of liner over spacer plate, under installation pressure ... 0.13 0.08 mm (.005 .003 in)(2) Height of four dowels above top surface of cylinder block:End dowels (Put 7M7456 Bearing Mount Compound on two end dowels at installation) ... 18.5 0.5 mm (.73 .02 in)Middle dowels ... 16.0 0.5 mm (.63 .02 in)(3) Dimension (new) from centerline of crankshaft bearing bore to top of block (top deck) ... 425.45 0.15 mm (16.750 .006 in)Minimum dimension from centerline of crankshaft bearing bore to top of block (top deck) ... 425.02 mm (16.733 in) The flatness across the whole contact surface of the block must be within 0.10 mm (.004 in) and within 0.05 mm (.002 in) for any 177 mm (7.0 in) section of the surface. The surface finish specification is 3.2 micrometers (125 micro-inches) maximum.(4) Bore in block for camshaft bearings ... 76.835 0.018 mm (3.0250 .0007 in) Install bearings with the oil holes in the bearings on the horizontal centerline. Make sure the bearing joint position is above the oil holes.(5) Bore in the block for the main bearings: Standard, original size (new) ... 129.891 0.013 mm (5.1138 .0005 in)0.64 mm (.025 in) larger than original size ... 130.526 0.013 mm (5.1388 .0005 in)(6) Distance from front of rear face of cylinder block to end of dowels ... 19.1 0.05 mm (.75 .02 in)(7) Width of main bearing cap ... 215.900 0.013 mm (8.5000 .0005 in)Width of block for main bearing cap ... 215.900 0.013 mm (8.5000 .0005 in)Clearance between main bearing cap and cylinder block ... 0.025 mm (.0009 in) tight to 0.025 mm (.0009 in) loose

Tightening Procedure For Main Bearings(8) Torque for the bolts that hold the caps for the main bearings: Install the main bearing caps with the marks (arrow) toward the front of the engine. Install each cap in the correct position by putting the number stamped on the bottom of the cap toward the corresponding number cast on left side of the cylinder block at the pan rail.a. Put 2P2506 Thread Lubricant on the threads of the bolts.b. Tighten the bolts first on the bearing tab side of the cap to ... 260 14 N m (190 10 lb ft)c. Tighten the bolts on the opposite side to ... 260 14 N m (190 10 lb ft)d. Put a mark on each bolt and cap.e. Tighten the bolts on the opposite side, from the mark ... 120 5°f. Tighten the bolts on the bearing tab side of the cap, from the mark ... 120 5°(9) Dimension (new) from centerline of crankshaft bearing bore to bottom of block (pan rails) ... 165.10 0.10

Tightening Procedure For Main Bearings(8) Torque for the bolts that hold the caps for the main bearings: Install the main bearing caps with the marks (arrow) toward the front of the engine. Install each cap in the correct position by putting the number stamped on the bottom of the cap toward the corresponding number cast on left side of the cylinder block at the pan rail.a. Put 2P2506 Thread Lubricant on the threads of the bolts.b. Tighten the bolts first on the bearing tab side of the cap to ... 260 14 N m (190 10 lb ft)c. Tighten the bolts on the opposite side to ... 260 14 N m (190 10 lb ft)d. Put a mark on each bolt and cap.e. Tighten the bolts on the opposite side, from the mark ... 120 5°f. Tighten the bolts on the bearing tab side of the cap, from the mark ... 120 5°(9) Dimension (new) from centerline of crankshaft bearing bore to bottom of block (pan rails) ... 165.10 0.10

Have questions with 101601-5233?

Group cross 101601-5233 ZEXEL

Hino

Hino

Hino

Hino

101601-5233

220005332A

INJECTION-PUMP ASSEMBLY

W06E

W06E