Information injection-pump assembly

ZEXEL

101601-5124

1016015124

HINO

220004892A

220004892a

Rating:

Service parts 101601-5124 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

236001730A

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Cross reference number

ZEXEL

101601-5124

1016015124

HINO

220004892A

220004892a

Zexel num

Bosch num

Firm num

Name

101601-5124

220004892A HINO

INJECTION-PUMP ASSEMBLY

W06E * K

W06E * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.07

3.13

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

8.9

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

47.4

45.4

49.4

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

8+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

6.8

5.3

8.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(8.9)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

47.4

46.4

48.4

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.25

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

58.3

54.3

62.3

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.15

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

36.7

32.7

40.7

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

D

Rack position

(R1+0.1)

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

52.2

48.2

56.2

Fixing the lever

*

Injection quantity adjustment_07

Adjusting point

E

Rack position

R1+0.3

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

29.2

25.2

33.2

Fixing the lever

*

Injection quantity adjustment_08

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

99

99

109

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1050--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

3.5

3.2

3.8

Remarks

Finish

Finish

Test data Ex:

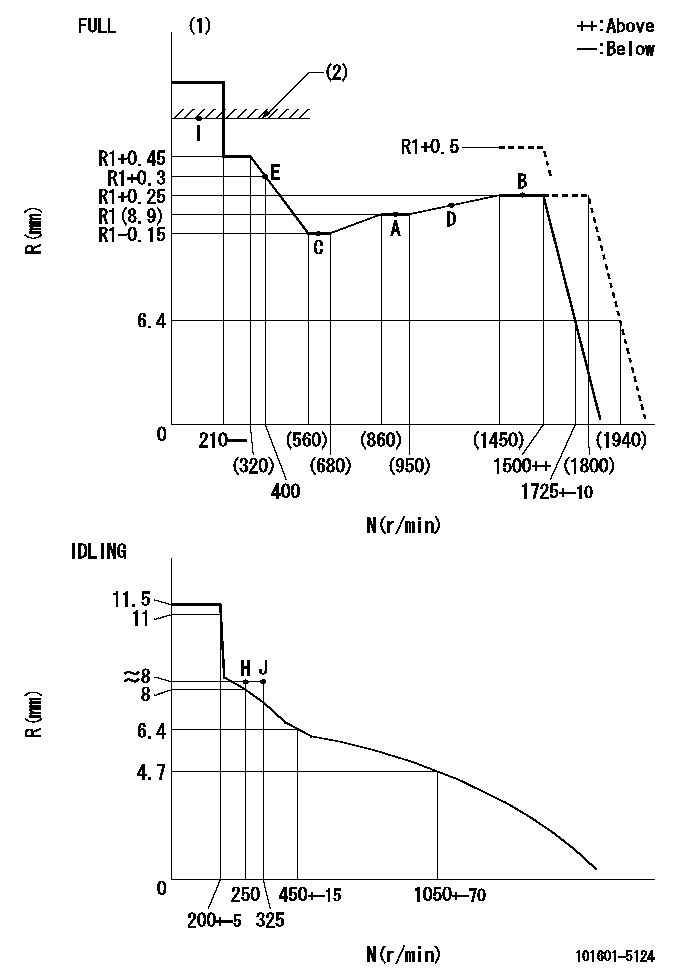

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=B98

----------

----------

T1=B98

----------

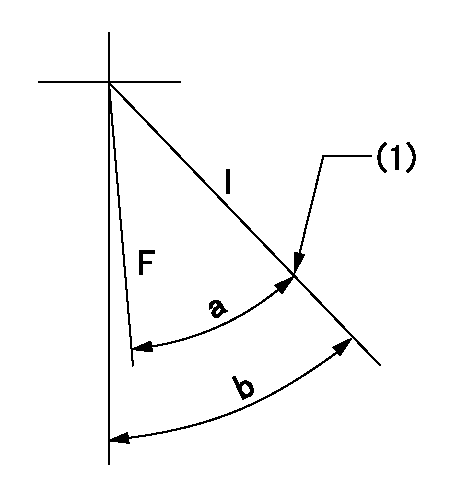

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=32deg+-3deg b=34deg+-5deg

----------

----------

a=32deg+-3deg b=34deg+-5deg

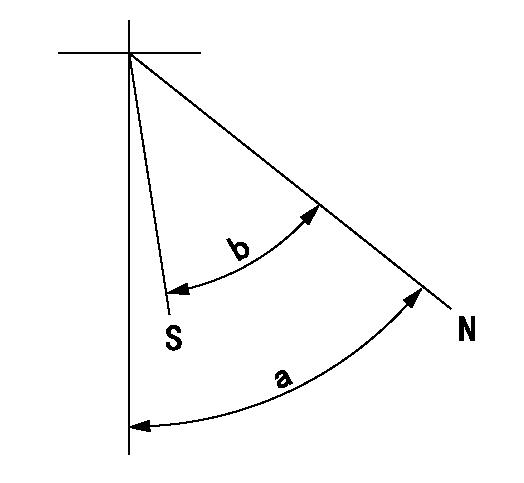

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=40deg+-5deg b=40deg+-5deg

----------

----------

a=40deg+-5deg b=40deg+-5deg

0000001501 TAMPER PROOF

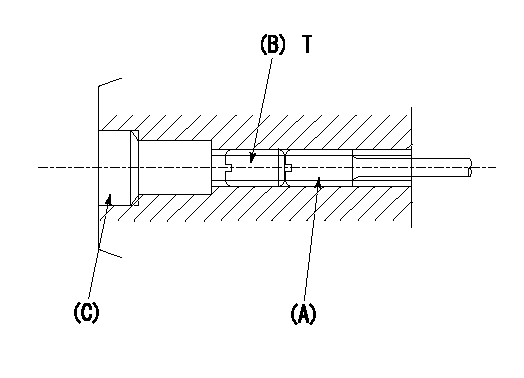

1. Method for setting tamperproof proofing

(1)After governor adjustment (torque cam phase adjustment), move the load lever to increase the full rack position to Ra.

(2)At pump speed N1, push in the screw (A) until the rack position is Rb.

(3)Temporarily caulk using the tip of a screwdriver

(4)Confirm that the rack at that time is at Rc.

(5)Lock using setscrew (B). (Tightening torque = T)

(6)Next, coat (C) with adhesive and then pressfit.

(7)Then, readjust the full rack position using the load lever.

----------

N1=1500r/min Ra=(0.4)mm Rb=R1(8.9)+0.5mm Rc=R1(8.9)+0.5mm

----------

T=3.4~4.9N-m(0.35~0.5Kgf-m)

----------

N1=1500r/min Ra=(0.4)mm Rb=R1(8.9)+0.5mm Rc=R1(8.9)+0.5mm

----------

T=3.4~4.9N-m(0.35~0.5Kgf-m)

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Overheating

Possible Causes/Corrections Low Coolant LevelIf the coolant level is too low, not enough coolant will go through the engine and radiator. This lack of coolant will not take enough heat from the engine and there will not be enough flow of coolant through the radiator to release the heat into the cooling air. Low coolant level is caused by leaks or wrong filling of the radiator. With the engine cool, be sure that coolant can be seen at the low end of the fill neck on the radiator top tank. Defective Temperature GaugeA temperature gauge which does not work correctly will not show the correct temperature. If the temperature gauge shows that the coolant temperature is too hot but other conditions are normal, either install a gauge you know is good or check the cooling system with the 4C6500 Digital Thermometer Group. Dirty RadiatorCheck the radiator for debris between the fins of the radiator core which prevents free air flow through the radiator core. Check the radiator for debris, dirt, or deposits on the inside of the radiator core which prevents free flow of coolant through the radiator. Loose Belt(s)Loose fan or water pump belts will cause a reduction in air or water flow. Tighten the belts according to Belt Tension Chart that is shown in Specification Section of this Service Manual. Defective Hose(s)Defective hoses with leaks can normally be seen. Hoses that have no visual leaks can "collapse" (pull together) during operation and cause a restriction in the flow of coolant. Hoses become soft and/or get cracks after a period of time. Hoses must be changed after 50,000 miles or a year of use. The inside can become loose, and the loose particles of the hose can cause a restriction in the flow of coolant. Shunt Line RestrictionA restriction of the shunt line from the radiator top tank to the engine front cover, or a shunt line not installed correctly, will cause a reduction in water pump efficiency. The result will be low coolant flow and overheating. Shutters Not Opening CorrectlyCheck the opening temperature of the shutters. The shutters must be completely closed at a temperature below the fully open temperature of the water temperature regulators. Also, verify that fan control switches or viscous fans are operating correctly. Defective Water Temperature RegulatorsA regulator that does not open, or only opens part of the way, can cause above normal heating. To test the thermostats, see the Testing and Adjusting Section of this Service Manual. Defective Water PumpA water pump with a loose impeller does not pump enough coolant for correct engine cooling. A loose impeller can be found by removing the water pump, and by pushing the shaft back and pulling it forward. If the impeller has no damage, check the impeller clearance. The clearance between the impeller and the housing is 0.56 to 1.50 mm (.022 to .059 in). Air In Cooling SystemAir can get into the cooling system in different ways. The most common causes are

Possible Causes/Corrections Low Coolant LevelIf the coolant level is too low, not enough coolant will go through the engine and radiator. This lack of coolant will not take enough heat from the engine and there will not be enough flow of coolant through the radiator to release the heat into the cooling air. Low coolant level is caused by leaks or wrong filling of the radiator. With the engine cool, be sure that coolant can be seen at the low end of the fill neck on the radiator top tank. Defective Temperature GaugeA temperature gauge which does not work correctly will not show the correct temperature. If the temperature gauge shows that the coolant temperature is too hot but other conditions are normal, either install a gauge you know is good or check the cooling system with the 4C6500 Digital Thermometer Group. Dirty RadiatorCheck the radiator for debris between the fins of the radiator core which prevents free air flow through the radiator core. Check the radiator for debris, dirt, or deposits on the inside of the radiator core which prevents free flow of coolant through the radiator. Loose Belt(s)Loose fan or water pump belts will cause a reduction in air or water flow. Tighten the belts according to Belt Tension Chart that is shown in Specification Section of this Service Manual. Defective Hose(s)Defective hoses with leaks can normally be seen. Hoses that have no visual leaks can "collapse" (pull together) during operation and cause a restriction in the flow of coolant. Hoses become soft and/or get cracks after a period of time. Hoses must be changed after 50,000 miles or a year of use. The inside can become loose, and the loose particles of the hose can cause a restriction in the flow of coolant. Shunt Line RestrictionA restriction of the shunt line from the radiator top tank to the engine front cover, or a shunt line not installed correctly, will cause a reduction in water pump efficiency. The result will be low coolant flow and overheating. Shutters Not Opening CorrectlyCheck the opening temperature of the shutters. The shutters must be completely closed at a temperature below the fully open temperature of the water temperature regulators. Also, verify that fan control switches or viscous fans are operating correctly. Defective Water Temperature RegulatorsA regulator that does not open, or only opens part of the way, can cause above normal heating. To test the thermostats, see the Testing and Adjusting Section of this Service Manual. Defective Water PumpA water pump with a loose impeller does not pump enough coolant for correct engine cooling. A loose impeller can be found by removing the water pump, and by pushing the shaft back and pulling it forward. If the impeller has no damage, check the impeller clearance. The clearance between the impeller and the housing is 0.56 to 1.50 mm (.022 to .059 in). Air In Cooling SystemAir can get into the cooling system in different ways. The most common causes are

Have questions with 101601-5124?

Group cross 101601-5124 ZEXEL

Hino

Hino

101601-5124

220004892A

INJECTION-PUMP ASSEMBLY

W06E

W06E