Information injection-pump assembly

ZEXEL

101601-5021

1016015021

HINO

220004701A

220004701a

Rating:

Service parts 101601-5021 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1593A

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

ZEXEL

101601-5021

1016015021

HINO

220004701A

220004701a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.07

3.13

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

8.7

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

46.6

44.6

48.6

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

8+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

8

6.5

9.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(8.7)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

46.6

45.6

47.6

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.3

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

45.2

43.2

47.2

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1+0.2

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

52

50

54

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

D

Rack position

R1-0.15

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

38

36

40

Fixing the lever

*

Injection quantity adjustment_07

Adjusting point

I

Rack position

13.5+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

95

105

Fixing the lever

*

Rack limit

*

Injection quantity adjustment_08

Adjusting point

E

Rack position

R1+0.35

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

28

24

32

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1300+50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1600

Advance angle

deg.

3.5

3.2

3.8

Remarks

Finish

Finish

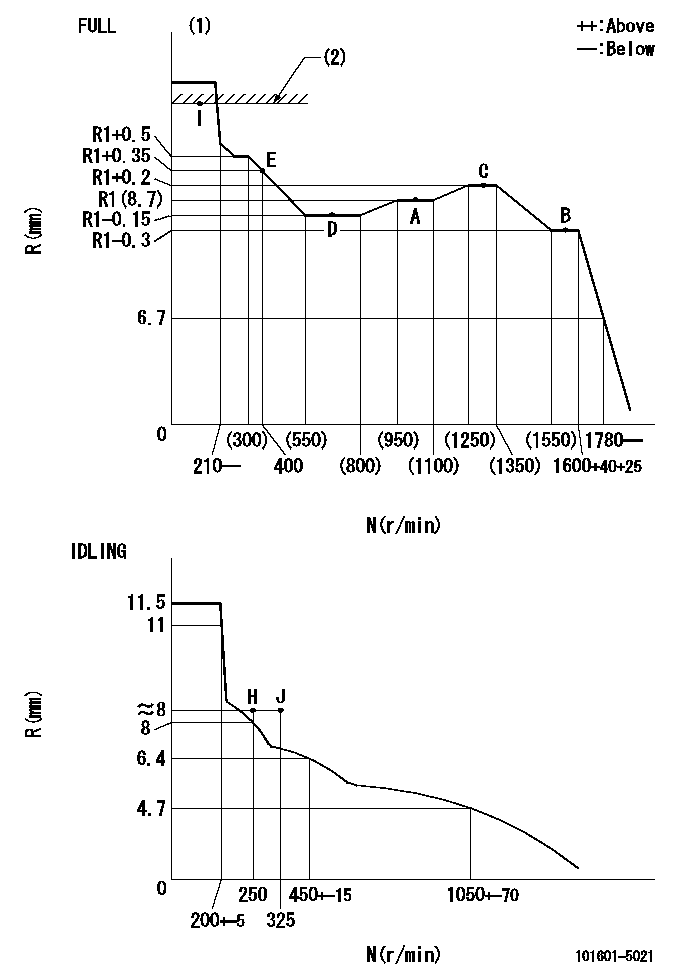

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=A76

----------

----------

T1=A76

----------

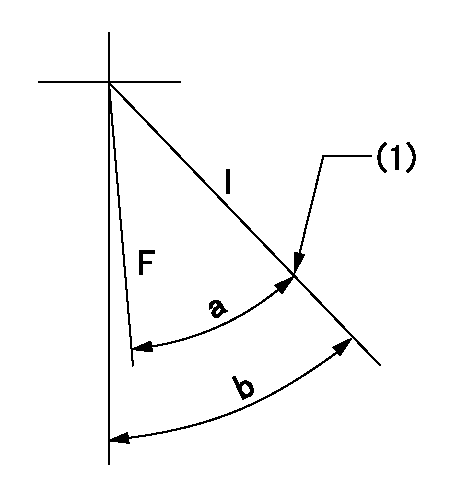

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=33deg+-3deg b=34deg+-5deg

----------

----------

a=33deg+-3deg b=34deg+-5deg

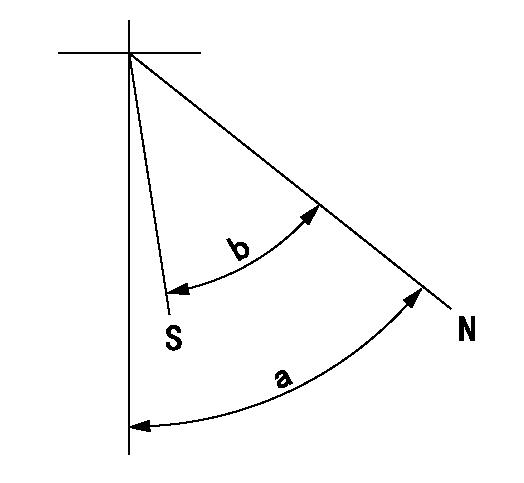

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=40deg+-5deg b=40deg+-5deg

----------

----------

a=40deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Problem 36: Soot In The Inlet Manifold

Probable Cause:1. On 3116 Engines a small amount of soot is normal. This is due to the design characteristics of the engine. Valve overlap allows the intake to open slightly before the exhaust stroke has been completed, which will allow some soot to be pushed into the inlet manifold.Problem 37: Air In Fuel

Probable Cause:With air in the fuel system the engine will normally be difficult to start, run rough and release a large amount of white smoke. If air is in the system, it will generally get in on the suction side of the fuel transfer pump. Check for leakage at the connections between the fuel tank and the fuel transfer pump. If leaks are found, tighten the connections or replace the lines. The fuel priming pump (if equipped) may be used to remove the air from the fuel filter and fuel gallery (in the cylinder head), and fill the fuel system with fuel from the fuel tank before the engine is started.If there are no visual leaks, remove the fuel supply line from the tank and connect it to an outside fuel supply. If this corrects the problem, the suction line (standpipe) inside the fuel tank has a leak.If this does not correct the problem, install a sight tube in the fuel return line and check the injectors to verify that they are properly seated. This can be accomplished by moving each injector (one at a time) to the "FUEL ON" position momentarily and checking the sight tube for any increase in air bubbles. Push on the rack bar on the exhaust manifold side of the injector to move the injector to the "FUEL ON" position. If an increase in air is found, then remove that injector. Check the tip seal (O-ring) and replace it if it is found to be defective. Inspect the injector sleeve for a smooth sealing surface for the injector to seat on. If any defects are noted, the sleeve can be reamed or it can be replaced if necessary.The temperature of an exhaust manifold port can be an indication of a cylinder that has air being delivered to it. Check the exhaust manifold temperatures and compare the results. A lower than normal cylinder temperature indicates that the cylinder may be receiving air from the injector.The color of the exhaust smoke can also indicate which cylinder has a combustion leak. Move each injector (one at a time) to the "FUEL ON" position momentarily while checking the color of the exhaust smoke. The cylinder that has air will produce smoke that is gray or white in color.

Probable Cause:1. On 3116 Engines a small amount of soot is normal. This is due to the design characteristics of the engine. Valve overlap allows the intake to open slightly before the exhaust stroke has been completed, which will allow some soot to be pushed into the inlet manifold.Problem 37: Air In Fuel

Probable Cause:With air in the fuel system the engine will normally be difficult to start, run rough and release a large amount of white smoke. If air is in the system, it will generally get in on the suction side of the fuel transfer pump. Check for leakage at the connections between the fuel tank and the fuel transfer pump. If leaks are found, tighten the connections or replace the lines. The fuel priming pump (if equipped) may be used to remove the air from the fuel filter and fuel gallery (in the cylinder head), and fill the fuel system with fuel from the fuel tank before the engine is started.If there are no visual leaks, remove the fuel supply line from the tank and connect it to an outside fuel supply. If this corrects the problem, the suction line (standpipe) inside the fuel tank has a leak.If this does not correct the problem, install a sight tube in the fuel return line and check the injectors to verify that they are properly seated. This can be accomplished by moving each injector (one at a time) to the "FUEL ON" position momentarily and checking the sight tube for any increase in air bubbles. Push on the rack bar on the exhaust manifold side of the injector to move the injector to the "FUEL ON" position. If an increase in air is found, then remove that injector. Check the tip seal (O-ring) and replace it if it is found to be defective. Inspect the injector sleeve for a smooth sealing surface for the injector to seat on. If any defects are noted, the sleeve can be reamed or it can be replaced if necessary.The temperature of an exhaust manifold port can be an indication of a cylinder that has air being delivered to it. Check the exhaust manifold temperatures and compare the results. A lower than normal cylinder temperature indicates that the cylinder may be receiving air from the injector.The color of the exhaust smoke can also indicate which cylinder has a combustion leak. Move each injector (one at a time) to the "FUEL ON" position momentarily while checking the color of the exhaust smoke. The cylinder that has air will produce smoke that is gray or white in color.