Information injection-pump assembly

ZEXEL

101601-3300

1016013300

KOMATSU

6138721130

6138721130

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Service parts 101601-3300 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

24.5(250)

15.

NOZZLE SET

Cross reference number

ZEXEL

101601-3300

1016013300

KOMATSU

6138721130

6138721130

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4

3.95

4.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

85.8

84.8

86.8

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.4+-0.5

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

15.5

14.3

16.7

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

10.3

Boost pressure

kPa

8

5.3

10.7

Boost pressure

mmHg

60

40

80

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

11.5

Boost pressure

kPa

38.7

38.7

38.7

Boost pressure

mmHg

290

290

290

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

1.4

0.9

1.9

Timer adjustment_04

Pump speed

r/min

1100

Advance angle

deg.

2.8

2.3

3.3

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

5

4.5

5.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

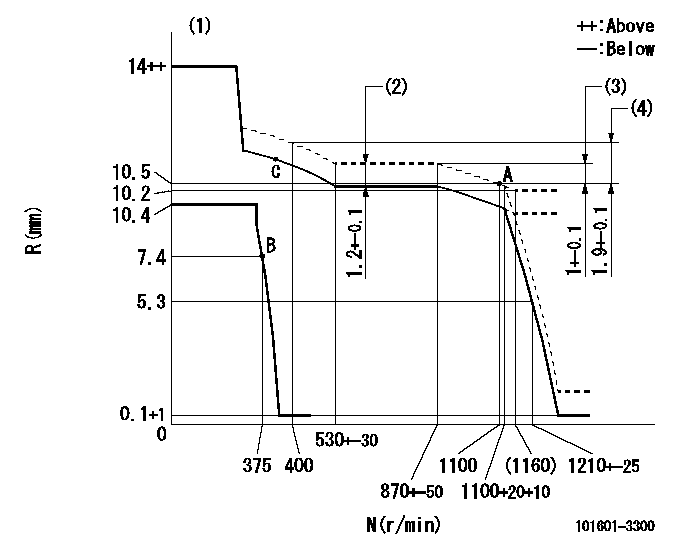

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Boost compensator stroke

(3)Rack difference between N = N1 and N = N2

(4)Rack difference between N = N3 and N = N4

----------

K=16 N1=1100r/min N2=750r/min N3=1100r/min N4=400r/min

----------

----------

K=16 N1=1100r/min N2=750r/min N3=1100r/min N4=400r/min

----------

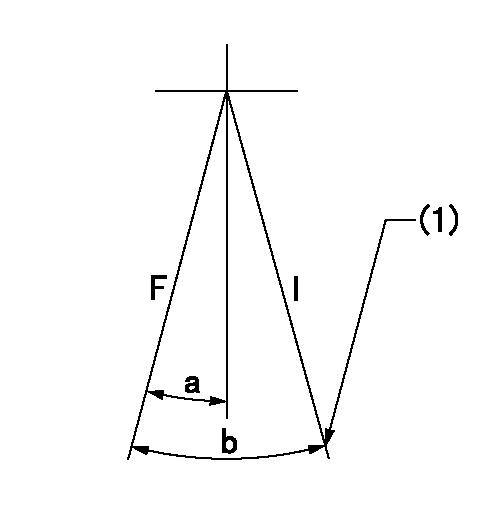

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=8deg+-5deg b=23deg+-5deg

----------

----------

a=8deg+-5deg b=23deg+-5deg

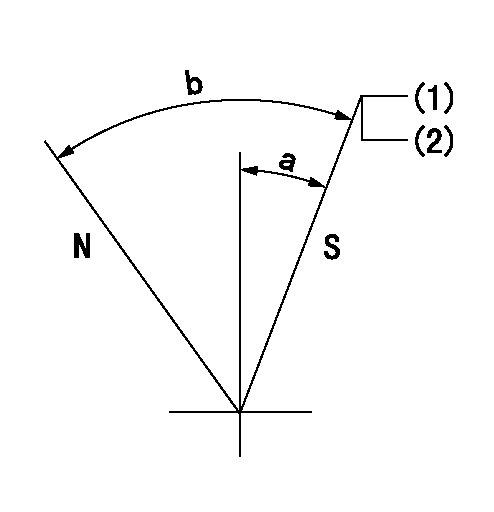

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At shipping

(2)Set the stopper bolt at speed = aa and rack position = bb.

----------

aa=0r/min bb=1-0.2mm

----------

a=21deg+-5deg b=(52deg)

----------

aa=0r/min bb=1-0.2mm

----------

a=21deg+-5deg b=(52deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(0deg)

----------

----------

a=(0deg)

Information:

1. The customer must be asked many questions to determine whether his complaint is valid, or whether his diagnosis of an actual problem is correct.Some of the questions that must be asked are as follows:a Does poor performance occur when the vehicle is operated at steady speed on a level road surface, or when vehicle is pulled up a grade? A positive response to either or both of the above conditions would indicate a low power (steady state) problem. Begin with Low Power Diagnosis.b. Does the poor performance always occur under the same conditions or is the problem intermittent (happens only occasionally)? This is a very important line of questioning to pursue. Any constant performance problem can normally be identified and the problem corrected. If an intermittent problem exists, the mechanic must be aware that the condition is only occasional, and must run certain tests several times in an attempt to force the malfunction condition. If the condition is not duplicated, the diagnosis that no problem exists will be incorrect, and the vehicle operator will again be confronted with the problem somewhere out on the road.c. Was the engine running rough or misfiring when the poor performance was noticed? A positive response to this questions will indicate the need to isolate the bad cylinder(s) and correct the problem. See section Cylinder Misfire.2. Check the crankcase oil level and the coolant level of the radiator. Start the engine and get to normal operating temperature. A slightly lower rpm (15 rpm below low limit) should be expected for the engine in vehicle than the rpm shown in the Fuel Setting And Related Information Fiche. This is caused by the parasitic loads of the engine accessories involved.3. With the engine running, the throttle must have enough travel for the governor control lever to break over (go past the normal governor stop for high idle position) a small amount when the throttle pedal is fully depressed. If full travel is not available, disconnect throttle linkage from governor lever. With throttle linkage disconnected, full travel of governor lever will indicate linkage problems, and the linkage will have to be adjusted. Limited travel of the governor lever will indicate a problem within the governor.4. Only a mechanic with the correct training should change the set point (balance point). The procedure is given in the Service Manual under the subject Governor Adjustments.5. If the set point (balance point) cannot be made correct with the high idle adjustment screw, there is a problem inside the governor. Disassemble the governor and check for damaged parts or wrong parts installed in the governor. Some common problems are worn bushings, worn spring seat, or a broken or wrong governor spring.6. Before 8T0500 Circuit Tester is installed, be sure to test the light for correct operation. Test light must come on when the clip of the wire is placed against the probe of the light (replace batteries or bulb if light does not come on). If light comes on