Information injection-pump assembly

ZEXEL

101601-3190

1016013190

KOMATSU

6138721560

6138721560

Rating:

Service parts 101601-3190 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

24.5(250)

15.

NOZZLE SET

Cross reference number

ZEXEL

101601-3190

1016013190

KOMATSU

6138721560

6138721560

Zexel num

Bosch num

Firm num

Name

101601-3190

6138721560 KOMATSU

INJECTION-PUMP ASSEMBLY

S6D110 * K

S6D110 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4

3.95

4.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

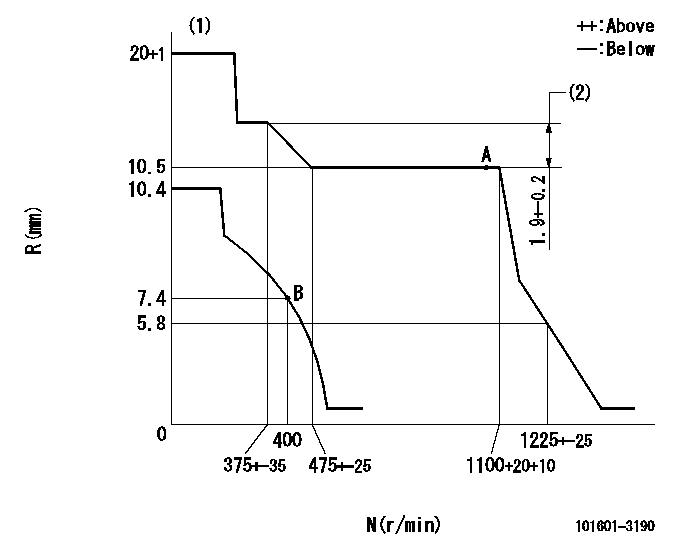

Injection quantity adjustment

Adjusting point

A

Rack position

10.5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

82

81

83

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.4+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

12.5

11.3

13.7

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

1.4

0.9

1.9

Timer adjustment_04

Pump speed

r/min

1100

Advance angle

deg.

3

2.5

3.5

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

3.5

3.5

3.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Rack difference between N = N1 and N = N2

----------

K=11 N1=1100r/min N2=330r/min

----------

----------

K=11 N1=1100r/min N2=330r/min

----------

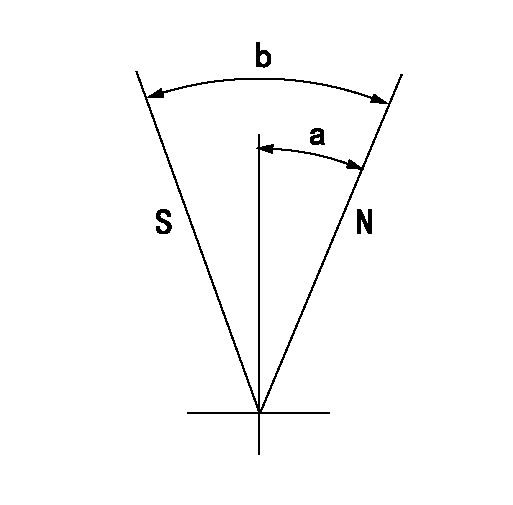

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=2deg+-5deg b=18deg+-5deg

----------

----------

a=2deg+-5deg b=18deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=27deg+-5deg b=53deg+-5deg

----------

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(0deg)

----------

----------

a=(0deg)

Information:

Illustration 8 g01455580

(6) 294-3395 Exhaust Support Assembly

Make four mounting holes for 294-3395 Exhaust Support Assembly (6) in the location (designated with a circle) which is shown in Illustration 8.

Illustration 9 g01456256

(17) 8T-4223 Hard Washers (18) 8T-4244 Nuts (19) 8T-4648 Bolt (20) 8T-4956 Bolt (21) 8T-6868 Bolts

Install exhaust support assembly (6) by using two 8T-6868 Bolts (21), one 8T-4648 Bolt (19), one 8T-4956 Bolt (20), four 8T-4223 Hard Washers (17), and four 8T-4244 Nuts (18). Refer to Illustration 9.

Illustration 10 g01456263

(9) 295-3044 Exhaust Support Groups (Lower half)

Remove the upper clamp from each 295-3044 Exhaust Support Group (9) by removing the two bolts and two hard washers. Keep the four bolts, the four hard washers, and the two upper clamps together. These parts will be reinstalled in Step 15.

Use four 8T-4956 Bolts (20) and four 8T-4223 Hard Washers (17) to install both 295-3044 Exhaust Support Groups (9) to exhaust support assembly (6). Refer to Illustration 10.

Illustration 11 g01456281

(5) 294-3065 Diesel Particulate Filter Group

To facilitate handling, remove the filter units from 294-3065 Diesel Particulate Filter Group (5) by removing the two clamps (including gaskets) closest to the rectangular intake manifold. Place the filter units, clamps, and gaskets aside.Note: Handle the removed filter units with extra care, as the internal structure is subject to damage due to impact, dropping, etc. Do not allow the inside of the filter units to get wet.

Install 294-3065 Diesel Particulate Filter Group (5) by aligning the mounting holes in the intake manifold with the mounting holes in the welded exhaust support assembly (7). Secure the intake manifold to the exhaust support assembly by using two 8T-4956 Bolts (20), two 8T-4223 Hard Washers (17), and two 8T-4244 Nuts (18). Refer to Illustration 11.

Reattach the lower filter unit to the intake manifold by reinstalling the clamp and the gasket that was removed in Step 12. Repeat for the upper filter unit.

Illustration 12 g01456285

Align the mounting holes in the upper half of 295-3044 Exhaust Support Group (9) with the mounting holes in the lower half of the exhaust support group (9). Reinstall the two bolts (9a) and the two hard washers (9b). Repeat for the other exhaust support group (9). Refer to Illustration 12.

Connect the straight end of exhaust tube assembly (8) to the manifold inlet pipe of the Diesel Particulate Filter Group. Use one 190-5341 Clamp (3)

Have questions with 101601-3190?

Group cross 101601-3190 ZEXEL

Komatsu

101601-3190

6138721560

INJECTION-PUMP ASSEMBLY

S6D110

S6D110