Information injection-pump assembly

BOSCH

9 400 610 197

9400610197

ZEXEL

101601-3170

1016013170

KOMATSU

6138721110

6138721110

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Service parts 101601-3170 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6138-12-3300

12.

Open Pre:MPa(Kqf/cm2)

24.5{250}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 610 197

9400610197

ZEXEL

101601-3170

1016013170

KOMATSU

6138721110

6138721110

Zexel num

Bosch num

Firm num

Name

9 400 610 197

6138721110 KOMATSU

INJECTION-PUMP ASSEMBLY

SA6D110 K 14BF INJECTION PUMP ASSY PE6AD PE

SA6D110 K 14BF INJECTION PUMP ASSY PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4

3.95

4.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

85.8

84.8

86.8

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

40

40

Boost pressure

mmHg

300

300

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.4+-0.5

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

15.5

14.3

16.7

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

10..5

Boost pressure

kPa

10.7

8

13.4

Boost pressure

mmHg

80

60

100

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

11.5

Boost pressure

kPa

26.7

26.7

26.7

Boost pressure

mmHg

200

200

200

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

1.4

0.9

1.9

Timer adjustment_04

Pump speed

r/min

1100

Advance angle

deg.

2.8

2.3

3.3

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

5

4.5

5.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

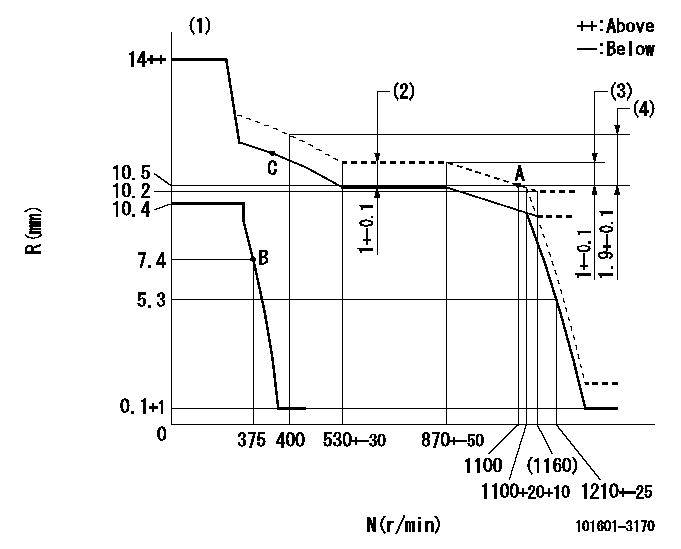

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Boost compensator stroke

(3)Rack difference between N = N1 and N = N2

(4)Rack difference between N = N3 and N = N4

----------

K=16 N1=1100r/min N2=750r/min N3=1100r/min N4=400r/min

----------

----------

K=16 N1=1100r/min N2=750r/min N3=1100r/min N4=400r/min

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=8deg+-5deg b=23deg+-5deg

----------

----------

a=8deg+-5deg b=23deg+-5deg

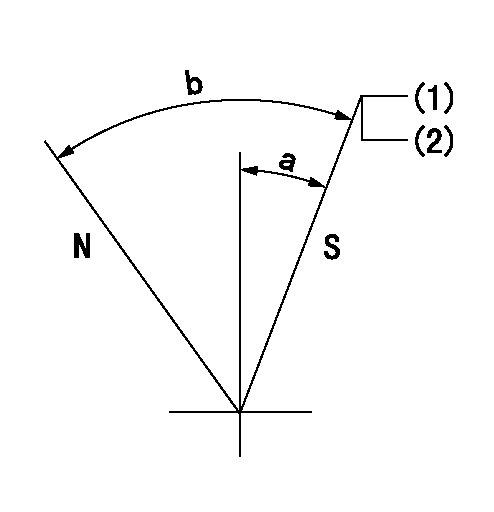

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At shipping

(2)Set the stopper bolt at speed = aa and rack position = bb (seal for delivery after setting the stopper bolt).

----------

aa=0r/min bb=1-0.2mm

----------

a=21deg+-5deg b=(52deg)

----------

aa=0r/min bb=1-0.2mm

----------

a=21deg+-5deg b=(52deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(0deg)

----------

----------

a=(0deg)

Information:

Introduction

Diesel Particulate Filters (DPF) and Catalytic Converter Mufflers (CCM) are not applicable to all engines. Some engines contain a DPF and a CCM device that were installed as original equipment to meet engine emissions certification requirements. However, some engines may have had the devices installed during a retrofit program for emissions reduction.

Do not perform any procedure in this Special Instruction until you read this information and you understand this information.Procedure for Shipping the Diesel Particulate Filters (DPF)

Wear goggles, gloves, protective clothing, and a National Institute for Occupational Safety and Health (NIOSH) approved P95 or N95 half-face respirator when handling a used Diesel Particulate Filter or Catalytic Converter Muffler. Failure to do so could result in personal injury.

Place all the used Diesel Particulate Filter (DPF) center sections, regardless of condition, into a 0.152 mm (0.006 inch) thick plastic bag. Make sure that the bag is sealed before placing the DPF into a shipping container. This must be performed in order to contain any constituents from the used DPF during shipping. New replacement diesel particulate filters may come with a 0.152 mm (0.006 inch) plastic bag that can be used for wrapping the used DPF.Procedure for Shipping the Catalytic Converter Mufflers (CCM)

Seal the inlet port and the outlet port on all used Catalytic Converter Mufflers (CCM) with rubber caps or plastic caps. Various sized plastic caps can be ordered from the Cat Shop Supplies and Hand Tools catalog. Reference caps and plugs under the Shop Supplies section. An alternative is to seal the inlet ports and outlet ports with a 0.152 mm (0.006 inch) thick sheet of plastic and 50 mm (2 inch) wide sealing tape with good adhesive properties before shipping. Sealing or capping must be performed in order to contain any constituents from the used CCM during shipping.

Diesel Particulate Filters (DPF) and Catalytic Converter Mufflers (CCM) are not applicable to all engines. Some engines contain a DPF and a CCM device that were installed as original equipment to meet engine emissions certification requirements. However, some engines may have had the devices installed during a retrofit program for emissions reduction.

Do not perform any procedure in this Special Instruction until you read this information and you understand this information.Procedure for Shipping the Diesel Particulate Filters (DPF)

Wear goggles, gloves, protective clothing, and a National Institute for Occupational Safety and Health (NIOSH) approved P95 or N95 half-face respirator when handling a used Diesel Particulate Filter or Catalytic Converter Muffler. Failure to do so could result in personal injury.

Place all the used Diesel Particulate Filter (DPF) center sections, regardless of condition, into a 0.152 mm (0.006 inch) thick plastic bag. Make sure that the bag is sealed before placing the DPF into a shipping container. This must be performed in order to contain any constituents from the used DPF during shipping. New replacement diesel particulate filters may come with a 0.152 mm (0.006 inch) plastic bag that can be used for wrapping the used DPF.Procedure for Shipping the Catalytic Converter Mufflers (CCM)

Seal the inlet port and the outlet port on all used Catalytic Converter Mufflers (CCM) with rubber caps or plastic caps. Various sized plastic caps can be ordered from the Cat Shop Supplies and Hand Tools catalog. Reference caps and plugs under the Shop Supplies section. An alternative is to seal the inlet ports and outlet ports with a 0.152 mm (0.006 inch) thick sheet of plastic and 50 mm (2 inch) wide sealing tape with good adhesive properties before shipping. Sealing or capping must be performed in order to contain any constituents from the used CCM during shipping.