Information injection-pump assembly

ZEXEL

101601-3060

1016013060

Rating:

Cross reference number

ZEXEL

101601-3060

1016013060

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4

3.95

4.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.4

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

78.2

77.2

79.2

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.2+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.9

7.7

10.1

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

1.4

0.9

1.9

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

3.5

3

4

Remarks

Finish

Finish

Test data Ex:

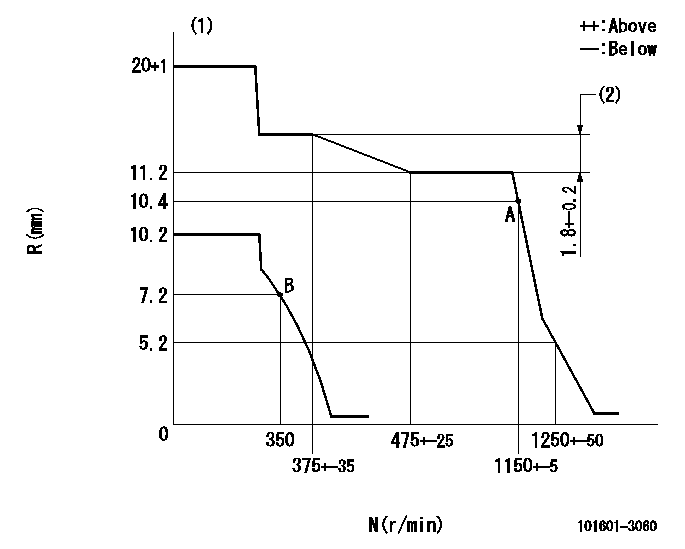

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Rack difference between N = N1 and N = N2

----------

K=6 N1=500r/min N2=330r/min

----------

----------

K=6 N1=500r/min N2=330r/min

----------

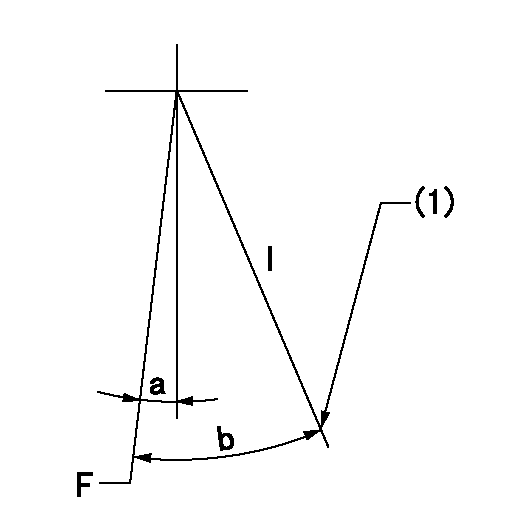

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=5deg+-5deg b=20deg+-5deg

----------

----------

a=5deg+-5deg b=20deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=27deg+-5deg b=53deg+-5deg

----------

----------

a=27deg+-5deg b=53deg+-5deg

Information:

Shunt-Type Cooling System

A shunt-type cooling system for the engine is recommended. A shunt-type cooling system radiator has a normal top tank (9) above the radiator core (10) and an expansion tank (2) above (any location) the top tank.An air and coolant tube (7) allows excess air and coolant in the radiator top tank to flow into the expansion tank. The expansion tank has a shunt line (3) which connects to the water pump (11) inlet. The shunt system maintains a positive head of coolant at the pump inlet to prevent cavitation in the pump under all operating conditions.When initially filling the cooling system, the coolant in expansion tank (2) flows through shunt line (3) to the water pump inlet, flows through pump (11), and fills engine cylinder block (13) from the bottom. Coolant flowing into the bottom of the block forces the air out through the top of temperature regulator housing (4), through tube (7) into expansion tank (2).It is a good procedure, after filling the system, to immediately start the engine and make certain the cooling system is full after a few minutes of engine operation. The operating water pump circulates the coolant through the engine, to drive out any air that could have been trapped in the engine. It may be necessary to add more coolant to fill the system.

SHUNT-TYPE RADIATOR COOLING SYSTEM-SCHEMATIC (Temperature regulator partially open)

1-Radiator cap (pressure regulating valve). 2-Expansion tank. 3-Shunt line tube. 4-Temperature regulator (thermostat) housing. 5-Cylinder liners (six). 6-Cylinder head. 7-Air and coolant bleed tube (between radiator top tank and expansion tank). 8-Radiator coolant bypass tube. 9-Radiator top tank. 10-Radiator core. 11-Water pump. 12-Engine lubricating oil cooler. 13-Cylinder block.Cylinder Head

CYLINDER HEAD-END VIEW

1-Precombustion chamber (six). 2-Spring (twelve). 3-Lock (twenty four). 4-Rotocoil assembly (twelve). 5-Rocker arm (twelve). 6-Push rod (twelve). 7-Air inlet manifold (in head). 8-Valve seat insert (six inlet, six exhaust). 9-Valve (six inlet, six exhaust).This overhead valve (OHV) cylinder head has one inlet and one exhaust valve for each engine cylinder. Rocker arms (5) are operated by the camshaft, in the engine cylinder block, cam followers (lifters) and push rods (6) which open and close valves (9) at the proper time. Each rocker arm has an adjustable contact to obtain the recommended valve lash (valve clearance). Each valve spring (2), to close a valve, is retained by locks (3) and a rotocoil assembly (4). The rotocoil will rotate a valve stem approximately one third of a degree each time the valve opens and closes. This will rotate the valve about one revolution per minute when the engine is operating at full load RPM.The valve bushings (guides) and valve seat inserts (8) can be removed, if necessary, and new ones installed. The valve seats are ground at 30° angles. The high heat resistant steel inlet valves and stellite exhaust valves are gound slightly less (about one fourth of a degree) than 30° angles. The interference angles between the valves and valve seats provide for better seating for longer periods of time.The inlet

A shunt-type cooling system for the engine is recommended. A shunt-type cooling system radiator has a normal top tank (9) above the radiator core (10) and an expansion tank (2) above (any location) the top tank.An air and coolant tube (7) allows excess air and coolant in the radiator top tank to flow into the expansion tank. The expansion tank has a shunt line (3) which connects to the water pump (11) inlet. The shunt system maintains a positive head of coolant at the pump inlet to prevent cavitation in the pump under all operating conditions.When initially filling the cooling system, the coolant in expansion tank (2) flows through shunt line (3) to the water pump inlet, flows through pump (11), and fills engine cylinder block (13) from the bottom. Coolant flowing into the bottom of the block forces the air out through the top of temperature regulator housing (4), through tube (7) into expansion tank (2).It is a good procedure, after filling the system, to immediately start the engine and make certain the cooling system is full after a few minutes of engine operation. The operating water pump circulates the coolant through the engine, to drive out any air that could have been trapped in the engine. It may be necessary to add more coolant to fill the system.

SHUNT-TYPE RADIATOR COOLING SYSTEM-SCHEMATIC (Temperature regulator partially open)

1-Radiator cap (pressure regulating valve). 2-Expansion tank. 3-Shunt line tube. 4-Temperature regulator (thermostat) housing. 5-Cylinder liners (six). 6-Cylinder head. 7-Air and coolant bleed tube (between radiator top tank and expansion tank). 8-Radiator coolant bypass tube. 9-Radiator top tank. 10-Radiator core. 11-Water pump. 12-Engine lubricating oil cooler. 13-Cylinder block.Cylinder Head

CYLINDER HEAD-END VIEW

1-Precombustion chamber (six). 2-Spring (twelve). 3-Lock (twenty four). 4-Rotocoil assembly (twelve). 5-Rocker arm (twelve). 6-Push rod (twelve). 7-Air inlet manifold (in head). 8-Valve seat insert (six inlet, six exhaust). 9-Valve (six inlet, six exhaust).This overhead valve (OHV) cylinder head has one inlet and one exhaust valve for each engine cylinder. Rocker arms (5) are operated by the camshaft, in the engine cylinder block, cam followers (lifters) and push rods (6) which open and close valves (9) at the proper time. Each rocker arm has an adjustable contact to obtain the recommended valve lash (valve clearance). Each valve spring (2), to close a valve, is retained by locks (3) and a rotocoil assembly (4). The rotocoil will rotate a valve stem approximately one third of a degree each time the valve opens and closes. This will rotate the valve about one revolution per minute when the engine is operating at full load RPM.The valve bushings (guides) and valve seat inserts (8) can be removed, if necessary, and new ones installed. The valve seats are ground at 30° angles. The high heat resistant steel inlet valves and stellite exhaust valves are gound slightly less (about one fourth of a degree) than 30° angles. The interference angles between the valves and valve seats provide for better seating for longer periods of time.The inlet