Information injection-pump assembly

ZEXEL

101601-3010

1016013010

Rating:

Cross reference number

ZEXEL

101601-3010

1016013010

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4

3.95

4.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.3

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

87.2

86.2

88.2

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.4+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

9.8

8.6

11

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

750

Advance angle

deg.

0.8

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

1.5

1

2

Timer adjustment_04

Pump speed

r/min

1250

Advance angle

deg.

4

3.5

4.5

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

5

4.5

5.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

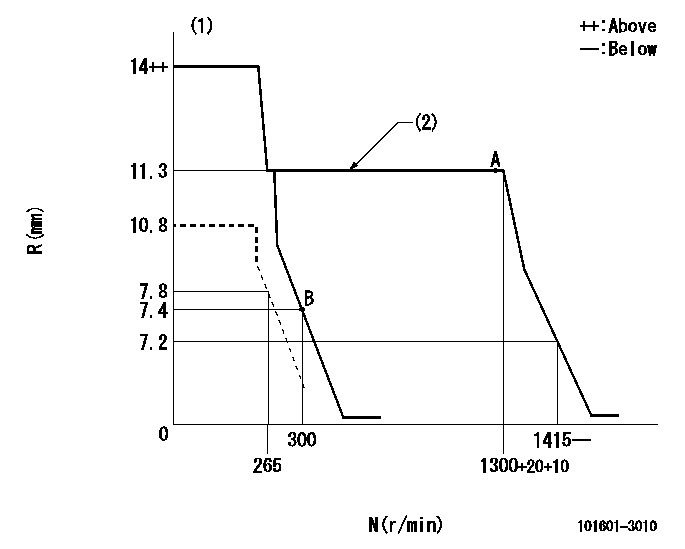

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Deliver without the torque control spring operating.

----------

K=9

----------

----------

K=9

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=29deg+-5deg b=40deg+-5deg

----------

----------

a=29deg+-5deg b=40deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=27deg+-5deg b=53deg+-5deg

----------

----------

a=27deg+-5deg b=53deg+-5deg

Information:

REMOVING CAM FOLLOWERS WITH MAGNET2. Rotate the crankshaft CLOCKWISE (as viewed from front of engine) until the timing mark on crankshaft gear is aligned with timing mark on camshaft large gear.3. Remove the plug from timing pin hole in fuel injection pump housing and install timing pin (1).4. Remove the tachometer drive adapter housing.5. On engines equipped with the hydraulic governor; Remove the automatic timing advance unit or the fuel injection pump camshaft drive gear by removing the tachometer drive shaft with a 9S5031 (5/8 in.) Deep Well Socket. Using puller group (2), thread the 9S8528 Bolt Assembly into the fuel injection pump camshaft. Do not force the bolt assembly. It should thread easily. Install the 9S8527 Bolt by threading it into the automatic timing advance unit or the fuel injection pump camshaft drive gear. Then tighten the 9S8527 Bolt with a wrench until the automatic timing advance unit or fuel injection pump camshaft drive gear "pops" loose.On engines equipped with the "Max-Min" governor; Loosen the automatic timing advance unit retaining bolt with a 8S2357 (9/16in.) Deep Well Socket. The bolt will first feel loose, then it will tighten again when the taper drive of the automatic timing advance unit starts to separate from the camshaft.

TIMING PIN AND PULLER INSTALLED

1. FT887 Timing Pin (Fabricated Tool). 2. 9S8520 Puller Group.6. Remove the camshaft thrust pin (3) from the rear of the cylinder block.

REMOVING THRUST PIN

3. Thrust pin.7. Pull the camshaft (4) out of the cylinder block, being careful to not damage the camshaft bearings or journals.

REMOVING CAMSHAFT

4. Camshaft.Install Camshaft

1. Lubricate the camshaft bearing surfaces with clean engine oil (SAE 30).2. Install the camshaft with timing mark on camshaft gear aligned with timing mark on crankshaft gear.3. Install the camshaft thrust pin in rear of cylinder block. Tighten the thrust pin to 35 5 lb. ft. (4.8 0.7 mkg).4. Position the automatic timing advance unit or fuel injection pump drive gear on the fuel injection pump camshaft. Install the tachometer drive shaft. Engines equipped with the hydraulic governor; Tighten retaining bolt to 32 2 lb. ft. (4.4 0.3 mkg). Engines equipped with the "Max-Min" governor; Tighten retaining bolt to 35 2 lb. ft. (4.8 0.3 mkg).5. Remove timing pin from fuel injection pump housing and install plug in timing pin hole.6. Install the cam followers in the same location from which they were removed. Always use new cam followers with a new camshaft. Be sure to put clean engine oil on the cam followers and camshaft lobes before installing the cam followers.