Information injection-pump assembly

ZEXEL

101601-2891

1016012891

HINO

220801212B

220801212b

Rating:

Cross reference number

ZEXEL

101601-2891

1016012891

HINO

220801212B

220801212b

Zexel num

Bosch num

Firm num

Name

101601-2891

220801212B HINO

INJECTION-PUMP ASSEMBLY

H07C * K

H07C * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.07

3.13

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

6.9

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

65

64

66

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5+-0.5

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

8

7

9

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

C

Rack position

10.8+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

125

125

135

Fixing the lever

*

Rack limit

*

Injection quantity adjustment_04

Adjusting point

E

Rack position

7.2

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

56

55

57

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1250

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1300

Advance angle

deg.

1.5

1

2

Timer adjustment_03

Pump speed

r/min

1430

Advance angle

deg.

4.5

4

5

Remarks

Finish

Finish

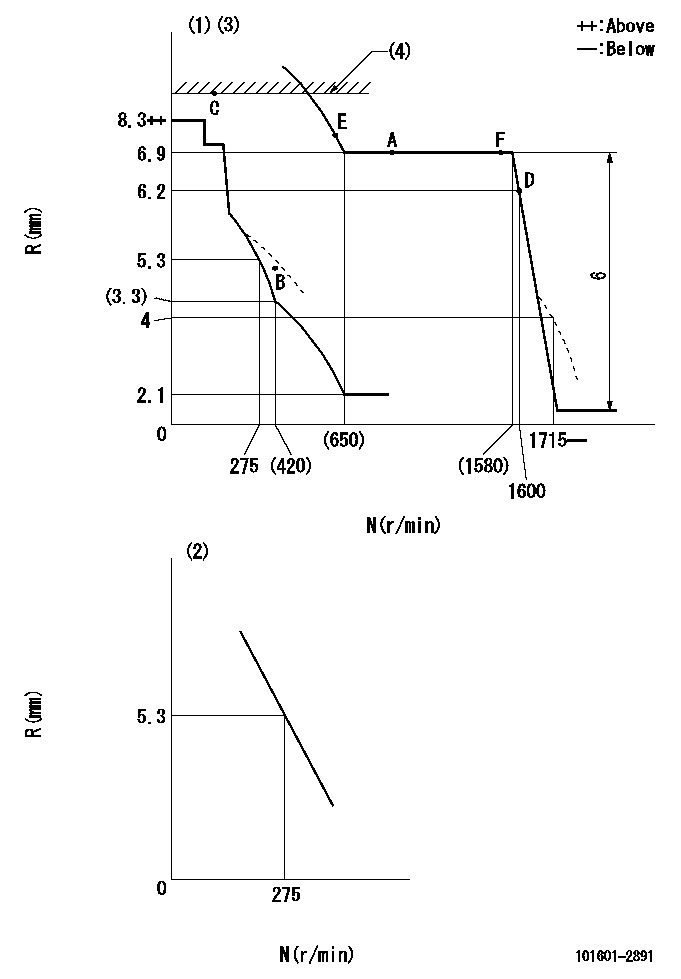

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Adjust with speed control lever at full position (minimum-maximum speed specification)

(2)Adjust with the load control lever in the full position (variable speed specification).

(3)Beginning of damper spring operation: DL

(4)RACK LIMIT

----------

DL=6-0.2mm

----------

----------

DL=6-0.2mm

----------

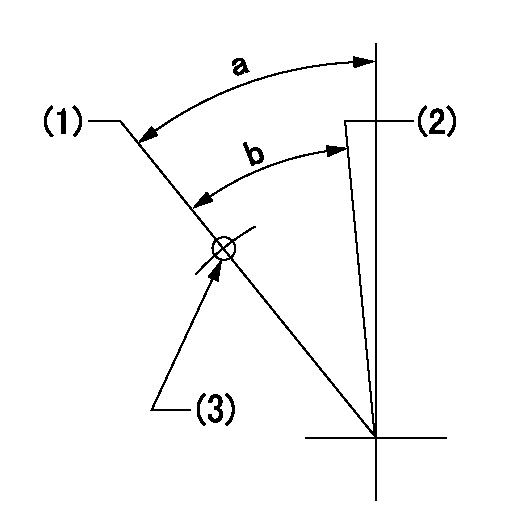

Speed control lever angle

F:Full speed

I:Idle

----------

----------

a=14deg+-5deg b=(20deg)+-5deg

----------

----------

a=14deg+-5deg b=(20deg)+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=65mm

----------

a=25.5deg+-3deg b=2deg+-5deg

----------

aa=65mm

----------

a=25.5deg+-3deg b=2deg+-5deg

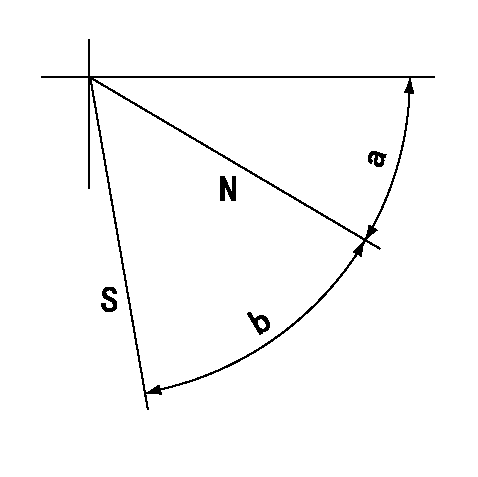

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=35deg+-5deg b=50deg+-5deg

----------

----------

a=35deg+-5deg b=50deg+-5deg

0000001201

(1)Minimum - maximum speed specification

(2)Variable speed specification

(3)Use the hole at R = aa

----------

aa=65mm

----------

a=39.5deg+-6deg b=(31.5deg)

----------

aa=65mm

----------

a=39.5deg+-6deg b=(31.5deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Engine Crankshaft Turns Free Exhaust Smoke Can Be Seen While Starting Recommended Procedure1. Cold Outside Temperatures It can be necessary to use starting aids, or warm engine oil or coolant, at temperatures below 10° F (-12° C).2. Air in Fuel System With air in the fuel system the engine will normally be difficult to start, run rough and release a large amount of white smoke. Remove the air from the fuel system by either loosening the cap on the tee at the fuel filter, or by loosening the fuel line nuts one at a time at the cylinder heads. Turn the engine with the starter until the fuel flow at this connection is free of air. If air is not removed in this way put 5 psi (0,35 kg/cm2) [CAUTION do not use more than 8 psi (0,56 kg/cm2)] of air pressure to the tank and check for leaks at connections between the fuel tank and the fuel transfer pump. If there are no leaks at the connections, remove the fuel supply line from the tank and connect to an outside fuel supply. If this corrects the problem the suction line (standpipe) inside the fuel tank has a leak.3. Low Quality Fuel Remove a small amount of fuel from the tank and check for water in the fuel. If there is water in the fuel, remove fuel from the tank until it is free of water and fill with a good quality fuel. Change the fuel filter and "prime" (remove the air and/or low quality fuel from the fuel system) the fuel system as per the Operation Guide (FEO45119). If there is no water in the fuel, using an outside supply of fuel, prime and start the engine. If engine starts correctly using different fuel, remove all fuel from the tank and fill with good quality fuel and prime the fuel system.4. Fuel Injection Timing Not Correct Check and make necessary adjustments as per Testing and Adjusting section of the Service Manual.5. Valve Adjustment Not Correct Check and make necessary adjustments as per Testing and Adjusting section of the Service Manual. Intake valve adjustment is .015 in. (0,38 mm) and exhaust valve adjustment is .025 in. (0,64 mm).6. Bad Fuel Nozzle(s) Remove the fuel nozzles and test as per Testing and Adjusting section of the Service Manual.7. Low Compression See the chart Misfiring and Running Rough. Exhaust Smoke Can Not Be Seen While Starting8. No Fuel in Tank Check fuel level visually (do not use the fuel gauge only). Be sure tank selection valve is open to the tank with fuel in it. Be sure valve in fuel line between the tanks is open.9. No Fuel From Fuel Injection Pump Loosen one or more of the fuel injection line nuts at the cylinder heads. With ignition switch on and accelerator in the fuel on position, turn the engine with the starter to be sure there is no fuel from the fuel injection pump. To find the cause

Have questions with 101601-2891?

Group cross 101601-2891 ZEXEL

Hino

101601-2891

220801212B

INJECTION-PUMP ASSEMBLY

H07C

H07C