Information injection-pump assembly

ZEXEL

101601-2270

1016012270

HINO

220001260B

220001260b

Rating:

Cross reference number

ZEXEL

101601-2270

1016012270

HINO

220001260B

220001260b

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-2220

Overflow valve opening pressure

kPa

123

103

143

Overflow valve opening pressure

kgf/cm2

1.25

1.05

1.45

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

1.9

1.85

1.95

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

12.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

122

119

125

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

12.8

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

125

123

127

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

12.8

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

129.7

127.7

131.7

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

13.1

Pump speed

r/min

1125

1125

1125

Average injection quantity

mm3/st.

135.5

132.5

138.5

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

7.1+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

23

20

26

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Injection quantity adjustment_06

Adjusting point

F

Rack position

15.5++

Pump speed

r/min

50

50

50

Average injection quantity

mm3/st.

140

140

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

450+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

600

Advance angle

deg.

1.3

0.8

1.8

Timer adjustment_03

Pump speed

r/min

800

Advance angle

deg.

3.3

2.8

3.8

Timer adjustment_04

Pump speed

r/min

1000

Advance angle

deg.

5.7

5.2

6.2

Timer adjustment_05

Pump speed

r/min

1150

Advance angle

deg.

8

7.5

8.5

Remarks

Finish

Finish

Test data Ex:

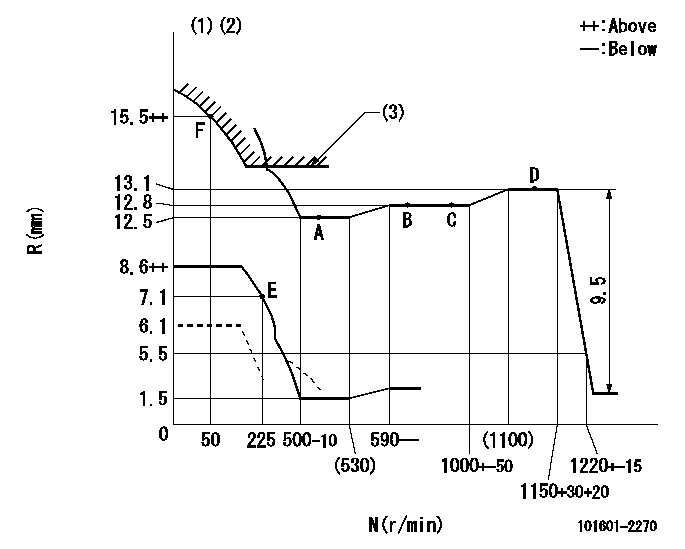

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Set the load lever's stop position so that R = aa (N = 0).

(2)Beginning of damper spring operation: DL

(3)Excess fuel setting for starting: SXL

----------

aa=6.1mm DL=5-0.2mm SXL=13.2+0.2mm

----------

----------

aa=6.1mm DL=5-0.2mm SXL=13.2+0.2mm

----------

0000000901

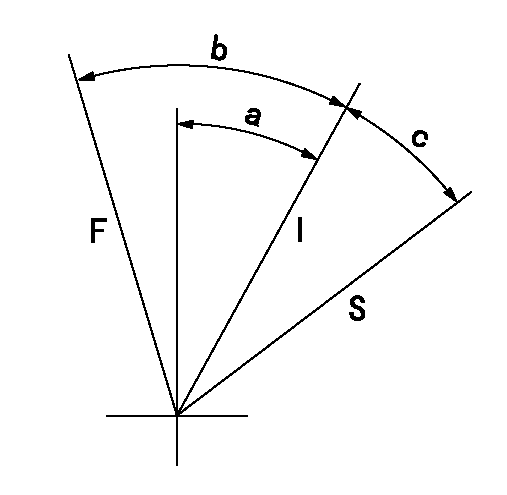

F:Full load

I:Idle

S:Stop

----------

----------

a=17deg+-3deg b=41deg+-3deg c=10deg+-2deg

----------

----------

a=17deg+-3deg b=41deg+-3deg c=10deg+-2deg

0000001501 MICRO SWITCH

Switch adjustment

Adjust the bolt so that the lower lever position is obtained when the switch is turned ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=285+-10r/min Ra=7.1mm

----------

----------

N1=285+-10r/min Ra=7.1mm

----------

Information:

1. Remove two bolts (1) from the top of the water pump. Loosen two bolts (2) in the water pump.

TYPICAL EXAMPLE2. Remove oil supply line (3) from the turbocharger. Remove oil return line (4) from the turbocharger.

TYPICAL EXAMPLE3. Remove the bolts (5) that hold the cylinder head to the cylinder block.

TYPICAL EXAMPLE4. Fasten a hoist to the cylinder head assembly (6). Remove the cylinder head assembly from the block. Weight of the assembly is 290 lb. (131 kg). Remove O-ring seal from hollow dowel. Remove cylinder head gasket (7) and water ferrules.

Do not put the cylinder head down on a flat surface. This can cause damage to the fuel injection valves.

Always install a new gasket between spacer plate and cylinder block before cylinder head is installed. See REMOVE SPACER PLATE.Install Cylinder Head

TYPICAL EXAMPLE1. Thoroughly clean the spacer plate and bottom surface of the cylinder head. Install a new head gasket (2), water ferrules (1) and O-ring seal (3) on the hollow dowel. Be sure a new gasket has been installed between spacer plate and cylinder block. See INSTALL SPACER PLATE.2. Fasten a hoist and install the cylinder head assembly (4) on the cylinder block. 3. Install the push rods and put the rocker shaft in position on the cylinder head. Put 5P3931 Anti-Seize Compound on the threads of the cylinder head and rocker shaft bolts. Install the bolts and washers and tighten the bolts as follows: 1. Tighten all bolts in number sequence to a torque of 115 lb. ft. (155 N m).2. Again tighten all bolts in number sequence to a torque of 185 13 lb. ft. (250 17 N m).3. Again tighten all bolts in number sequence (hand torque only) to a torque of 185 13 lb. ft. (250 17 N m).4. Tighten all bolts in letter sequence to a torque of 32 5 lb. ft. (43 7 N m).4. Make adjustment of valves to have a clearance of .015 in. (0.38 mm) for intake and .025 in. (0.64 mm) for exhaust.

TYPICAL EXAMPLE5. Install oil return line (6) on the turbocharger.6. Install oil supply line (5) on the turbocharger. 7. Tighten the two bolts (8) in the water pump.8. Install the two bolts (7) that hold the water pump to the cylinder head.end by: a) install fuel injection lines

TYPICAL EXAMPLE2. Remove oil supply line (3) from the turbocharger. Remove oil return line (4) from the turbocharger.

TYPICAL EXAMPLE3. Remove the bolts (5) that hold the cylinder head to the cylinder block.

TYPICAL EXAMPLE4. Fasten a hoist to the cylinder head assembly (6). Remove the cylinder head assembly from the block. Weight of the assembly is 290 lb. (131 kg). Remove O-ring seal from hollow dowel. Remove cylinder head gasket (7) and water ferrules.

Do not put the cylinder head down on a flat surface. This can cause damage to the fuel injection valves.

Always install a new gasket between spacer plate and cylinder block before cylinder head is installed. See REMOVE SPACER PLATE.Install Cylinder Head

TYPICAL EXAMPLE1. Thoroughly clean the spacer plate and bottom surface of the cylinder head. Install a new head gasket (2), water ferrules (1) and O-ring seal (3) on the hollow dowel. Be sure a new gasket has been installed between spacer plate and cylinder block. See INSTALL SPACER PLATE.2. Fasten a hoist and install the cylinder head assembly (4) on the cylinder block. 3. Install the push rods and put the rocker shaft in position on the cylinder head. Put 5P3931 Anti-Seize Compound on the threads of the cylinder head and rocker shaft bolts. Install the bolts and washers and tighten the bolts as follows: 1. Tighten all bolts in number sequence to a torque of 115 lb. ft. (155 N m).2. Again tighten all bolts in number sequence to a torque of 185 13 lb. ft. (250 17 N m).3. Again tighten all bolts in number sequence (hand torque only) to a torque of 185 13 lb. ft. (250 17 N m).4. Tighten all bolts in letter sequence to a torque of 32 5 lb. ft. (43 7 N m).4. Make adjustment of valves to have a clearance of .015 in. (0.38 mm) for intake and .025 in. (0.64 mm) for exhaust.

TYPICAL EXAMPLE5. Install oil return line (6) on the turbocharger.6. Install oil supply line (5) on the turbocharger. 7. Tighten the two bolts (8) in the water pump.8. Install the two bolts (7) that hold the water pump to the cylinder head.end by: a) install fuel injection lines