Information injection-pump assembly

ZEXEL

101601-2260

1016012260

HINO

220001150B

220001150b

Rating:

Cross reference number

ZEXEL

101601-2260

1016012260

HINO

220001150B

220001150b

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4120

Overflow valve opening pressure

kPa

122.5

98

147

Overflow valve opening pressure

kgf/cm2

1.25

1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

1.9

1.85

1.95

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

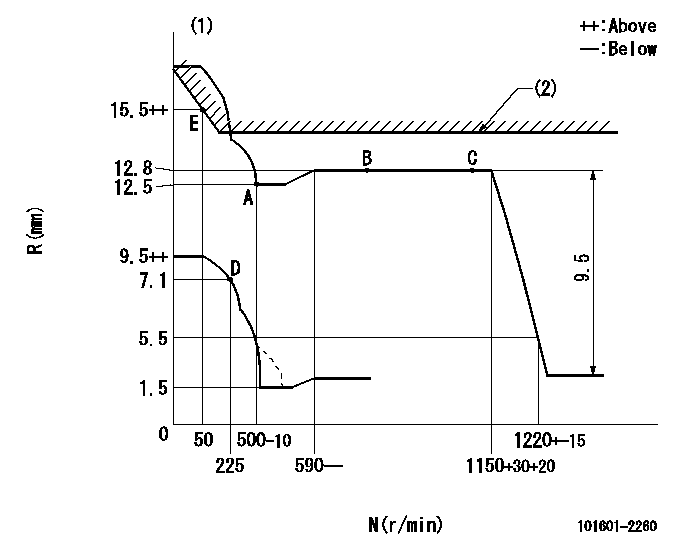

Injection quantity adjustment

Adjusting point

A

Rack position

12.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

122

119

125

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

12.8

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

129.7

127.7

131.7

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

12.8

Pump speed

r/min

1125

1125

1125

Average injection quantity

mm3/st.

131.3

128.3

134.3

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

7.1+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

23

20

26

Max. variation between cylinders

%

0

-13

13

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

15.5++

Pump speed

r/min

50

50

50

Average injection quantity

mm3/st.

140

140

Remarks

Excess fuel for starting.

Excess fuel for starting.

Timer adjustment

Pump speed

r/min

450+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

600

Advance angle

deg.

1.3

0.8

1.8

Timer adjustment_03

Pump speed

r/min

800

Advance angle

deg.

3.3

2.8

3.8

Timer adjustment_04

Pump speed

r/min

1000

Advance angle

deg.

5.7

5.2

6.2

Timer adjustment_05

Pump speed

r/min

1150

Advance angle

deg.

8

7.5

8.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)RACK LIMIT: RAL

----------

DL=5-0.2mm RAL=13+0.2mm

----------

----------

DL=5-0.2mm RAL=13+0.2mm

----------

0000000901

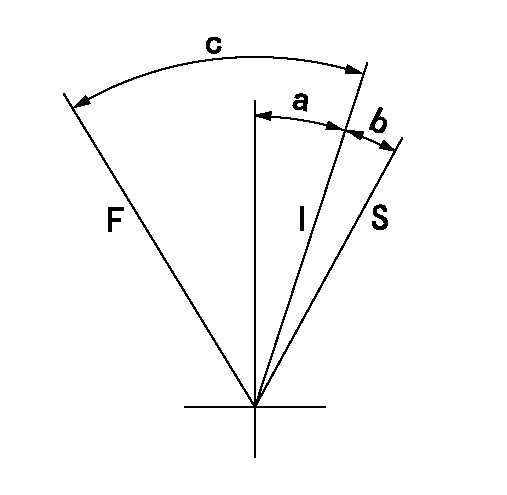

F:Full load

I:Idle

S:Stop

----------

----------

a=17deg+-3deg b=10deg+-2deg c=41deg+-3deg

----------

----------

a=17deg+-3deg b=10deg+-2deg c=41deg+-3deg

0000001501 MICRO SWITCH

Switch adjustment

Adjust the bolt so that the lower lever position is obtained when the switch is turned ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=285+-10r/min Ra=7.1mm

----------

----------

N1=285+-10r/min Ra=7.1mm

----------

Information:

start by:a) remove turbocharger 1. Put the turbocharger in position on tool (A). Move tool (A) so the compressor housing is up. 2. For installation alignment purposes, make a mark on the center housing and turbine housing. Bend down the lock plates and remove six bolts (1). If some of the bolts are hard to remove, put penetrating oil on the bolt and hit the flat of the bolt head with a punch and hammer. 3. Lift the center housing and turbine wheel out of the turbine housing. If the assembly is hard to get apart, lift up on the compressor housing and hit the turbine housing with a soft hammer. 4. Remove clamp (2) from the compressor housing. For installation alignment purposes, make a mark on the center housing and the compressor housing. 5. Lift the center housing out of the compressor housing. Put the turbine wheel in tooling (B).6. Remove nut (3) with a universal socket. Remove O-ring (4).

Do not put a side force on the shaft when the nut is removed.

7. Heat the compressor wheel in oil for no more than ten minutes. The temperature of the oil must be 350° 25°F (176° 14°C).

The bearing heating oil used to heat the compressor wheel must have a flash point above 400°F (204°C).

8. Immediately after removing the compressor wheel from the oil, put the center housing in a press and use tooling (C) and (D) to remove the compressor wheel and center housing from the shaft.

Do not let the turbine wheel hit the bottom of the press.

9. Put the turbine wheel in tooling (B) and remove ring (6) and shroud (5). 10. Remove three bolts (7) and the three lock plates from center housing (8). 11. Remove plate (9) with tool (E). Remove the O-ring from plate (9). 12. Remove spacer (10) from plate (9). Remove collar (11) and thrust bearing (15). Remove bearing (12) and put a long dye mark on the top face of the bearing. Use tool (F) to remove rings (16) and (13). Remove bearing (17) and put a short dye mark on the top face of the bearing. Remove ring (14) with tool (F). The dye marks are for identification when installing the bearings.13. Inspect all parts and install new parts if needed. Use Special Instruction Form No. GMG00153-01, Turbocharger Reconditioning, Form No. FEG45138, Analyzing Turbocharger Failure and Video Tape JEG08054 (1/2 inch reel) (JEG09052-cassette), Turbocharger Reconditioning I (AIRESEARCH) for references.Assemble Turbocharger

1. Make sure all oil passages are open and clean. Put clean engine oil on all parts before assembly. 2. Install ring (3) with tool (A). Install bearing (4) with the short dye mark up. Install rings (2) and (1) with tool (A). Rings (1), (2) and (3) must be installed with the round edge toward the bearing. 3. Install shroud (5) on the turbine shaft. Install ring (6). Put 6V2055 High Vacuum Grease on ring (6) and fill the groove for the ring to one half depth all

Do not put a side force on the shaft when the nut is removed.

7. Heat the compressor wheel in oil for no more than ten minutes. The temperature of the oil must be 350° 25°F (176° 14°C).

The bearing heating oil used to heat the compressor wheel must have a flash point above 400°F (204°C).

8. Immediately after removing the compressor wheel from the oil, put the center housing in a press and use tooling (C) and (D) to remove the compressor wheel and center housing from the shaft.

Do not let the turbine wheel hit the bottom of the press.

9. Put the turbine wheel in tooling (B) and remove ring (6) and shroud (5). 10. Remove three bolts (7) and the three lock plates from center housing (8). 11. Remove plate (9) with tool (E). Remove the O-ring from plate (9). 12. Remove spacer (10) from plate (9). Remove collar (11) and thrust bearing (15). Remove bearing (12) and put a long dye mark on the top face of the bearing. Use tool (F) to remove rings (16) and (13). Remove bearing (17) and put a short dye mark on the top face of the bearing. Remove ring (14) with tool (F). The dye marks are for identification when installing the bearings.13. Inspect all parts and install new parts if needed. Use Special Instruction Form No. GMG00153-01, Turbocharger Reconditioning, Form No. FEG45138, Analyzing Turbocharger Failure and Video Tape JEG08054 (1/2 inch reel) (JEG09052-cassette), Turbocharger Reconditioning I (AIRESEARCH) for references.Assemble Turbocharger

1. Make sure all oil passages are open and clean. Put clean engine oil on all parts before assembly. 2. Install ring (3) with tool (A). Install bearing (4) with the short dye mark up. Install rings (2) and (1) with tool (A). Rings (1), (2) and (3) must be installed with the round edge toward the bearing. 3. Install shroud (5) on the turbine shaft. Install ring (6). Put 6V2055 High Vacuum Grease on ring (6) and fill the groove for the ring to one half depth all