Information injection-pump assembly

ZEXEL

101601-0600

1016010600

ISUZU

5156001065

5156001065

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Cross reference number

ZEXEL

101601-0600

1016010600

ISUZU

5156001065

5156001065

Zexel num

Bosch num

Firm num

Name

101601-0600

5156001065 ISUZU

INJECTION-PUMP ASSEMBLY

6BB1 *

6BB1 *

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.4

2.35

2.45

Rack position

R=9.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

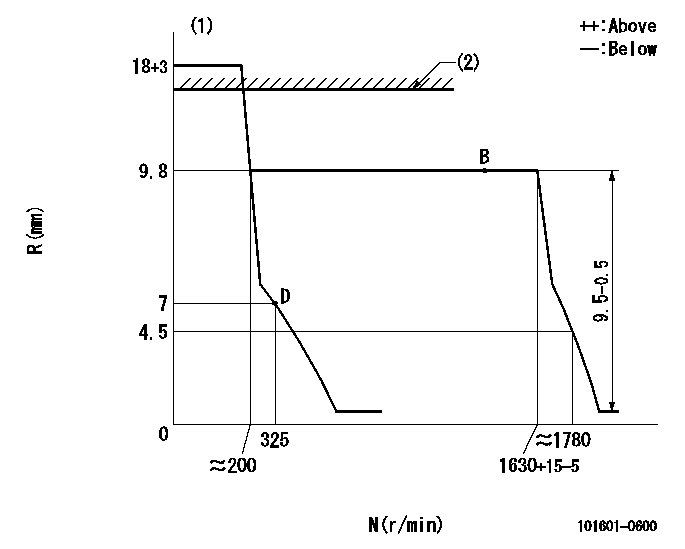

Injection quantity adjustment

Adjusting point

B

Rack position

9.8

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

56.6

55.1

58.1

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

D

Rack position

7

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

8

6.7

9.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)At rack cap installation: R1

----------

K=6 R1=(17.5)mm

----------

----------

K=6 R1=(17.5)mm

----------

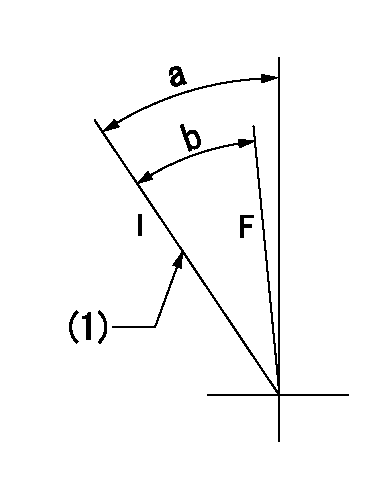

Speed control lever angle

F:Full speed

I:Idle

(1)Fix idle side stopper bolt.

----------

----------

a=33deg+-3deg b=26.5deg+-5deg

----------

----------

a=33deg+-3deg b=26.5deg+-5deg

Information:

Problem

Some connecting rod assemblies may have been machined incorrectly. A machining discrepancy in the rod eye bore may not allow the rod eye bushing outside diameter to make complete contact with the rod eye bore. This can reduce the life of the bushing.

Affected Product

Model & Identification Number

3508 (7YG2069, 95Y1016, 96Y1725-1727, 23Z6865, 23Z6867-6871, 23Z6884-6885, 23Z6889, 23Z6892, 68Z903-906, 68Z909 , 68Z912, 68Z914, 69Z745-761)

3508B (7SM77, 7SM82-83)

G3508 (9TG141-144)

3512 (49Y835, 51Y760, 24Z7930-7932, 24Z7935-7948, 24Z7951, 24Z7953-7965, 24Z7969, 24Z7971, 24Z7980-7982, 24Z7985, 24Z7990-7991, 66Z718-721, 66Z1444-1445)

3512B (4TN99, 8RM201-202, 6WN137, 6FL145)

G3512 (7NJ287-290, 7NJ297)

3516 (5SJ542-543, 7CL416, 7CL419-421, 4XF673, 25Z5550-5551, 25Z5553-5555, 25Z5559, 25Z5567, 25Z5569-5574, 25Z5577, 25Z5584-5585, 28Z646, 29Z1227-1230, 67Z1447-1449)

3516B (9AN121, 8KN146-149, 8KN153-154, 7RN464-470)

G3516 (8LD46, 4EK1304-1305, 4EK1307-1313, 4EK1327, 4EK1334)

777D (3PR466-468, 3PR472-478, 3PR480)

Parts Needed

1 - 6I1356 Seal1 - 6I1357 Seal1 - 1013281 Rod Assembly1 - 1077330 Bearing (if necessary)1 - 1106991 Gasket-Head1 - 1106992 Gasket The parts are listed as one per failure. As many as 8, 12, or 16 parts may be required depending on the engine model. Additional parts not listed may be required depending on arrangement.

Action Required

See the attached procedure.

Owner Notification

U.S. and Canadian owners will receive the attached Owner Notification.

Service Claim Allowances

Labor Hour Breakdown For repairs of less than a complete set, 6.0 hours of labor per cylinder are reimbursable.

Allow 1.0 hour labor for testing of an engine and an additional 2.0 hours for setup/tear down.

The rod inspection, rod replacement and engine testing setup/tear down labor hours listed above are based on a basic 3500 Series Commercial Engine repaired in a dealer shop. Engines with various attachments, at customer sites or in a vehicle chassis may require additional labor hours. Those additional hours must be explained in the claim details.Costs incurred for emergency parts orders, for return of connecting rods, oil analysis, equipment needs to complete repairs or engine testing should be listed as other expenses and explained.

Parts Disposition

Return the removed defective connecting rod(s) to:

Caterpillar, Inc.

Attn: Jack Sanders - PI3047

Building B Claims Room

3701 State Road 26 East

Lafayette, Indiana 47905

Package the defective connecting rod(s) in it's original packaging carton for return shipment to Lafayette. Return defective parts within 24 hours of completion of removal from the engine. Call Matt Hannon at (765) 448-5138 or e-mail HANNOMJ with shipping Bill Number, part number, quantity in shipment, and Dealer name and location.

Dealers outside of North America should ship by Air Freight.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

Attach.(1-Owner Notification)(2-Rework Procedure)Copy Of Owner Notification For U.S. And Canadian Owners

Rework Procedure

Connecting Rod Inspection

- The inspection of the connecting rod date code can be performed by removing the cylinder block side covers (left side typically most accessible) and viewing the date code. Rotation of the crankshaft and use of a mirror and a flash light will assist in viewing the date code on some rods. The date code is located on the side of the side of the rod cap at cap to rod joint. The date code format is YYMXXXX where (YY) is the year, (M) is a letter denoting the month, and (XXXX) is a sequence number. Rods with date

Some connecting rod assemblies may have been machined incorrectly. A machining discrepancy in the rod eye bore may not allow the rod eye bushing outside diameter to make complete contact with the rod eye bore. This can reduce the life of the bushing.

Affected Product

Model & Identification Number

3508 (7YG2069, 95Y1016, 96Y1725-1727, 23Z6865, 23Z6867-6871, 23Z6884-6885, 23Z6889, 23Z6892, 68Z903-906, 68Z909 , 68Z912, 68Z914, 69Z745-761)

3508B (7SM77, 7SM82-83)

G3508 (9TG141-144)

3512 (49Y835, 51Y760, 24Z7930-7932, 24Z7935-7948, 24Z7951, 24Z7953-7965, 24Z7969, 24Z7971, 24Z7980-7982, 24Z7985, 24Z7990-7991, 66Z718-721, 66Z1444-1445)

3512B (4TN99, 8RM201-202, 6WN137, 6FL145)

G3512 (7NJ287-290, 7NJ297)

3516 (5SJ542-543, 7CL416, 7CL419-421, 4XF673, 25Z5550-5551, 25Z5553-5555, 25Z5559, 25Z5567, 25Z5569-5574, 25Z5577, 25Z5584-5585, 28Z646, 29Z1227-1230, 67Z1447-1449)

3516B (9AN121, 8KN146-149, 8KN153-154, 7RN464-470)

G3516 (8LD46, 4EK1304-1305, 4EK1307-1313, 4EK1327, 4EK1334)

777D (3PR466-468, 3PR472-478, 3PR480)

Parts Needed

1 - 6I1356 Seal1 - 6I1357 Seal1 - 1013281 Rod Assembly1 - 1077330 Bearing (if necessary)1 - 1106991 Gasket-Head1 - 1106992 Gasket The parts are listed as one per failure. As many as 8, 12, or 16 parts may be required depending on the engine model. Additional parts not listed may be required depending on arrangement.

Action Required

See the attached procedure.

Owner Notification

U.S. and Canadian owners will receive the attached Owner Notification.

Service Claim Allowances

Labor Hour Breakdown For repairs of less than a complete set, 6.0 hours of labor per cylinder are reimbursable.

Allow 1.0 hour labor for testing of an engine and an additional 2.0 hours for setup/tear down.

The rod inspection, rod replacement and engine testing setup/tear down labor hours listed above are based on a basic 3500 Series Commercial Engine repaired in a dealer shop. Engines with various attachments, at customer sites or in a vehicle chassis may require additional labor hours. Those additional hours must be explained in the claim details.Costs incurred for emergency parts orders, for return of connecting rods, oil analysis, equipment needs to complete repairs or engine testing should be listed as other expenses and explained.

Parts Disposition

Return the removed defective connecting rod(s) to:

Caterpillar, Inc.

Attn: Jack Sanders - PI3047

Building B Claims Room

3701 State Road 26 East

Lafayette, Indiana 47905

Package the defective connecting rod(s) in it's original packaging carton for return shipment to Lafayette. Return defective parts within 24 hours of completion of removal from the engine. Call Matt Hannon at (765) 448-5138 or e-mail HANNOMJ with shipping Bill Number, part number, quantity in shipment, and Dealer name and location.

Dealers outside of North America should ship by Air Freight.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

Attach.(1-Owner Notification)(2-Rework Procedure)Copy Of Owner Notification For U.S. And Canadian Owners

Rework Procedure

Connecting Rod Inspection

- The inspection of the connecting rod date code can be performed by removing the cylinder block side covers (left side typically most accessible) and viewing the date code. Rotation of the crankshaft and use of a mirror and a flash light will assist in viewing the date code on some rods. The date code is located on the side of the side of the rod cap at cap to rod joint. The date code format is YYMXXXX where (YY) is the year, (M) is a letter denoting the month, and (XXXX) is a sequence number. Rods with date

Have questions with 101601-0600?

Group cross 101601-0600 ZEXEL

Isuzu

101601-0600

5156001065

INJECTION-PUMP ASSEMBLY

6BB1

6BB1