Information injection-pump assembly

ZEXEL

101501-2060

1015012060

HINO

220009740A

220009740a

Rating:

Cross reference number

ZEXEL

101501-2060

1015012060

HINO

220009740A

220009740a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131425-0320

Overflow valve opening pressure

kPa

108

88

128

Overflow valve opening pressure

kgf/cm2

1.1

0.9

1.3

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-2-4-5-

3

Pre-stroke

mm

4

3.97

4.03

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 72 71.75 72.25

Cyl.1-2 deg. 72 71.75 72.25

Difference between angles 2

Cal 1-4 deg. 144 143.75 144.25

Cal 1-4 deg. 144 143.75 144.25

Difference between angles 3

Cal 1-5 deg. 216 215.75 216.25

Cal 1-5 deg. 216 215.75 216.25

Difference between angles 4

Cal 1-3 deg. 288 287.75 288.25

Cal 1-3 deg. 288 287.75 288.25

Injection quantity adjustment

Adjusting point

-

Rack position

12.2

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

100

98.4

101.6

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.5+-0.5

Pump speed

r/min

415

415

415

Each cylinder's injection qty

mm3/st.

12

11

13

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.2)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

100

99

101

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.6

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

103

99

107

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1+0.45

Pump speed

r/min

1160

1160

1160

Average injection quantity

mm3/st.

105.5

101.5

109.5

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

D

Rack position

R1-0.75

Pump speed

r/min

580

580

580

Average injection quantity

mm3/st.

84

80

88

Fixing the lever

*

Injection quantity adjustment_07

Adjusting point

E

Rack position

R1-0.9

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

77

71

83

Fixing the lever

*

Injection quantity adjustment_08

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

170

170

180

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Load

1/5

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.3

Load

1/5

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

1

0.7

1.3

Load

5/5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

1190++

Advance angle

deg.

1

0.7

1.3

Load

2/5

Timer adjustment_05

Pump speed

r/min

(1300-50

)

Advance angle

deg.

1

0.7

1.3

Load

5/5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_06

Pump speed

r/min

1450-50

Advance angle

deg.

5.5

5.2

5.8

Load

5/5

Remarks

Finish

Finish

Test data Ex:

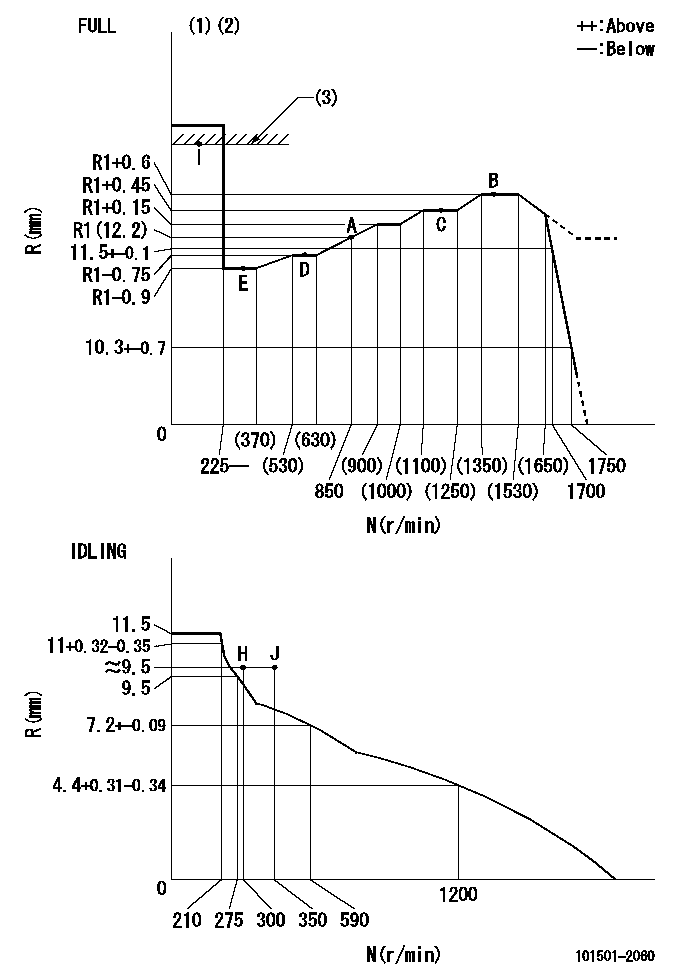

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=K64

----------

----------

T1=K64

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=46mm

----------

a=8deg+-5deg b=38deg+-3deg

----------

aa=46mm

----------

a=8deg+-5deg b=38deg+-3deg

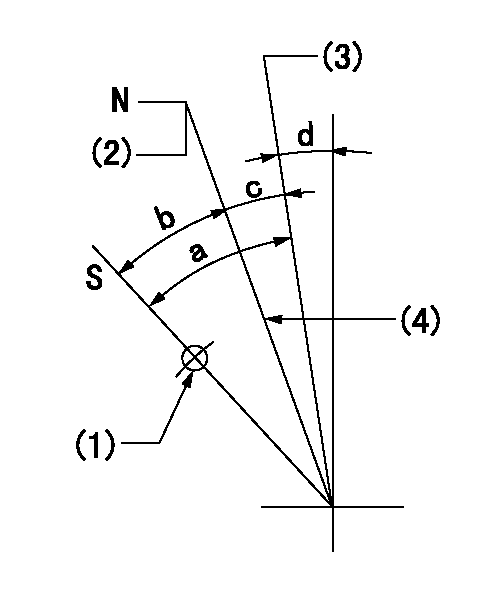

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Use the hole at R = aa

(2)Rack position bb

(3)Free

(4)Set the stopper screw. (After setting, apply red paint.)

----------

aa=50mm bb=16.2+-0.2mm

----------

a=(36deg) b=26deg+-5deg c=10deg+-5deg d=0deg+-5deg

----------

aa=50mm bb=16.2+-0.2mm

----------

a=(36deg) b=26deg+-5deg c=10deg+-5deg d=0deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Information:

Image1.1.2

2. Remove existing 215-2705 cap (Image 1.2.1), and replace with new 272-7102 cap, utilizing the existing cap screws (Image 1.2.1). Insure that threads are coated with Thread Lock P/N 9S-3263 or 4C-4030 and torque cap screws to 7(+/-1) Nm.

Image1.2.1

3. Install new 263-2905 switches (Image 1.3.1) into caps insuring that threads are coated with P/N 4C-5598 High temperature Anti-Seize and torque to 16(+/-2) Nm

Image1.3.1

4. Connect new switch to the applicable wiring harness. Install ladder clips as shown (Image 1.4.1), using 0S-1588 Bolts coated with P/N 4C-5598 High Temperature Anti-Seize to replace the top two existing bolts as shown. Torque these bolts to 47 (+/-9) Nm.

Image1.4.1

Image1.4.2

5. IMPORTANT - Tie-wrap new switch wiring to existing solenoid wiring as shown (Images 1.4.1 & 1.4.2), to prevent thermal damage to wiring.

6. Install information films P/N 179-0133 on electrically actuated Air Shut Offs over the existing films on the solenoids as shown in (Image 1.6.1) or install information films for hydraulically actuated Air Shut Offs over the existing films on the valve covers as shown in (Image 1.6.2).

Films in languages other than English are available under the following part numbers:

-Arabic 297-2613

-French 297-2614

-German 297-2615

-Spanish 297-2616

-Portuguese 297-2617

-Russian 297-2618

Image1.6.1

Image1.6.2

Important Notes:

1. If a new switch is to be painted, mask the vent holes around the perimeter of the switch before painting and be sure to remove the masking after the paint dries.

2. Test completed modifications as detailed below for the specific ECM installed on the engine (ADEM 2 or ADEM 3).

OPERATIONAL TEST - ADEM 2 Engine Control Modules ONLY

Note: (For Troubleshooting purposes) The ASO switches are normally closed switches that are in the closed state when the air shutoff valves are latched in the open ("Run") position. If the air shutoff valves are in the closed ("Stop") position, the switch will be in the open state, causing an emergency stop and shutting the engine down. This also prevents the engine from starting.

DO NOT START THE ENGINE! Ensure that the engine control is in the "OFF" position.

1. Ensure that both air shutoff gates are latched in the OPEN position and ensure that both air shutoff switches are connected. Turn on the power to the engine control panel. Both air shutoff gates should remain open. If both air shutoff gates do not remain open, check the wiring for the air shutoff switches.

2. With the power for the engine control panel in the ON position, activate the "EMERGENCY STOP" switch. Both of the air shutoff gates should close. If both air shutoff gates close, proceed to step 3. If both air shutoff gates do not close, check the wiring for the air shutoff switches and check the wiring for the solenoids. Activate the "EMERGENCY STOP" switch again. When both air shutoff gates close, proceed to step 3.

3. Turn the power to the engine control panel to the OFF position. Ensure that the "EMERGENCY STOP" switch is in the RUN position. Latch only the right side air shutoff gate to the OPEN position. Turn the power for the engine control panel to