Information injection-pump assembly

ZEXEL

101495-3580

1014953580

KOMATSU

6205711150

6205711150

Rating:

Cross reference number

ZEXEL

101495-3580

1014953580

KOMATSU

6205711150

6205711150

Zexel num

Bosch num

Firm num

Name

101495-3580

6205711150 KOMATSU

INJECTION-PUMP ASSEMBLY

S4D95LE-2 K

S4D95LE-2 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-4-3

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 90 89.5 90.5

Cyl.1-2 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cal 1-3 deg. 270 269.5 270.5

Cal 1-3 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.7

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

83

82

84

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

8+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

8

7

9

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

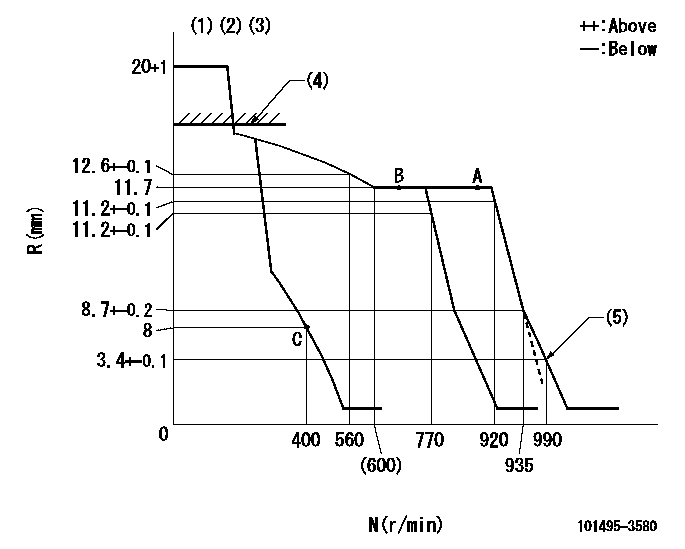

Test data Ex:

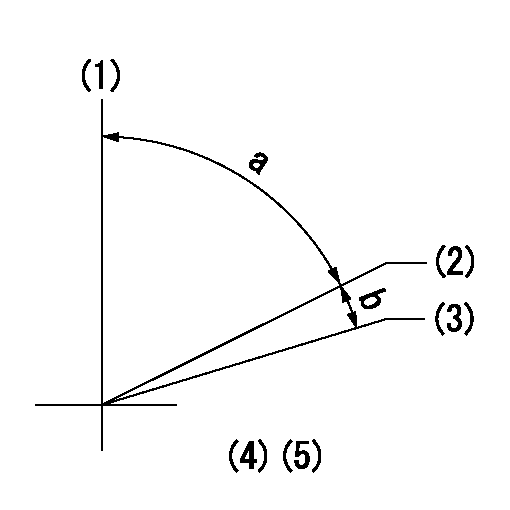

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)At governor adjustment, set the stop lever at the normal position.

(4)RACK CAP: R1

(5)Set idle sub-spring

----------

K=7 R1=(17.5)mm

----------

----------

K=7 R1=(17.5)mm

----------

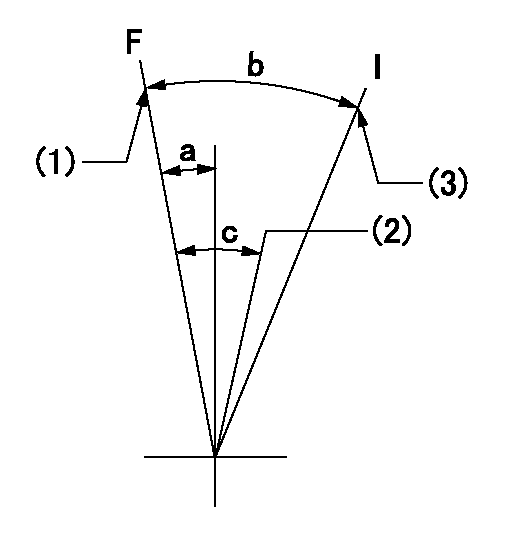

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa. ( At delivery )

(2)Set the pump speed at bb.

(3)Stopper bolt setting

----------

aa=920r/min bb=770r/min

----------

a=2deg+-5deg b=22deg+-5deg c=6deg+-5deg

----------

aa=920r/min bb=770r/min

----------

a=2deg+-5deg b=22deg+-5deg c=6deg+-5deg

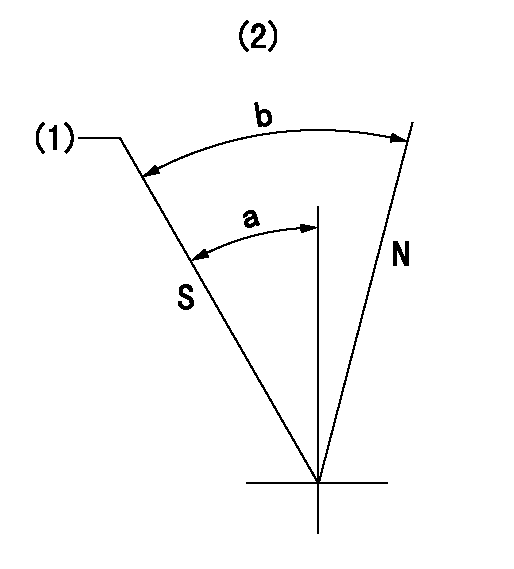

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa, speed = bb (stamp at delivery)

(2)No return spring

----------

aa=1-0.5mm bb=0r/min

----------

a=27.5deg+-5deg b=(55deg)

----------

aa=1-0.5mm bb=0r/min

----------

a=27.5deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Position of key groove at No 1 cylinder's beginning of injection

(3)Stamp aligning marks on the pump housing flange.

(4)-

(5)-

----------

----------

a=58deg+-3deg b=2deg+-30min

----------

----------

a=58deg+-3deg b=2deg+-30min

Information:

The fuel system consists of the transfer pump, fuel filter, shutoff solenoid, injection pumps, timing advance unit, governor, injection lines, nozzles and excess fuel return lines.The diaphragm-type fuel transfer pump mounts on the fuel injection pump housing and is driven by a lobe on the injection pump camshaft. The pump draws fuel from the vehicle supply tank and delivers it to a spin-on throw-away type filter. The filter is a combination primary-secondary element.Filtered fuel flows through a fuel shutoff solenoid, mounted on the fuel injection pump housing, into a fuel manifold. The solenoid operates electrically and stops fuel flow when the vehicle ignition system is off.Fuel in the manifold flows through the barrel assembly inlet port into the area above the injection pump plunger. During injection, the camshaft forces the plunger upward in the barrel. The end of the plunger closes the inlet port and forces the fuel out through high pressure injection lines to the nozzles.The injection nozzles are located under the valve cover and are held in place by clamps. The nozzle tip projects from the head into the cylinder bore. Atomized fuel is sprayed in a cone-shaped pattern through four orifices into the cylinder.During injection, a small amount of fuel leaks past the valve guide in the nozzle body to lubricate its moving parts. Any excess leakage flows from the nozzle to a fuel return manifold under the valve cover of each cylinder head. External lines connect the manifolds and return the fuel to the tank.Fuel Injection Pump Operation

Fuel enters the fuel injection pump housing from the fuel filter through the

Fuel enters the fuel injection pump housing from the fuel filter through the

Have questions with 101495-3580?

Group cross 101495-3580 ZEXEL

Komatsu

Komatsu

Komatsu

101495-3580

6205711150

INJECTION-PUMP ASSEMBLY

S4D95LE-2

S4D95LE-2