Information injection-pump assembly

ZEXEL

101495-3500

1014953500

Rating:

Cross reference number

ZEXEL

101495-3500

1014953500

Zexel num

Bosch num

Firm num

Name

101495-3500

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-4-3

Pre-stroke

mm

3.2

3.15

3.25

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 90 89.5 90.5

Cyl.1-2 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cal 1-3 deg. 270 269.5 270.5

Cal 1-3 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.8

Pump speed

r/min

925

925

925

Average injection quantity

mm3/st.

63

62

64

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.3+-0.5

Pump speed

r/min

575

575

575

Average injection quantity

mm3/st.

8

7

9

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

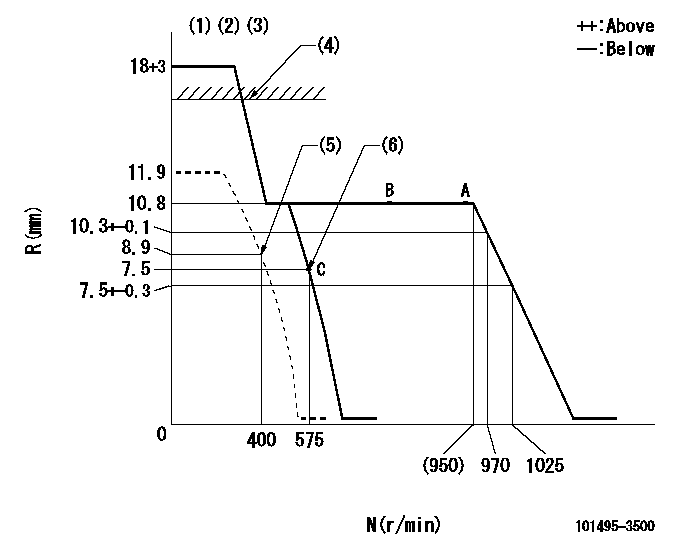

Governor adjustment

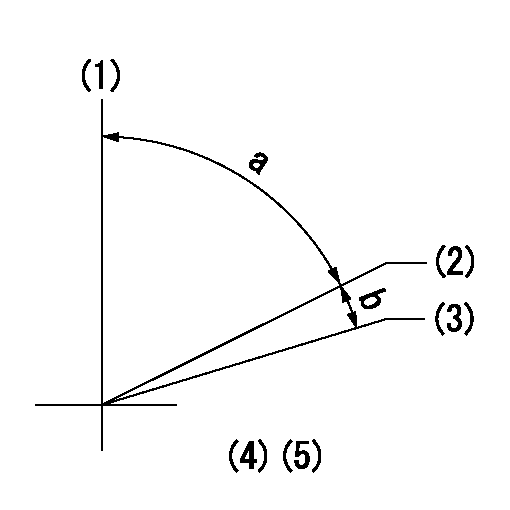

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Deliver without the torque control spring operating.

(4)RACK CAP: R1

(5)Set idle sub-spring

(6)Main spring setting

----------

K=6 R1=(17.5)mm

----------

----------

K=6 R1=(17.5)mm

----------

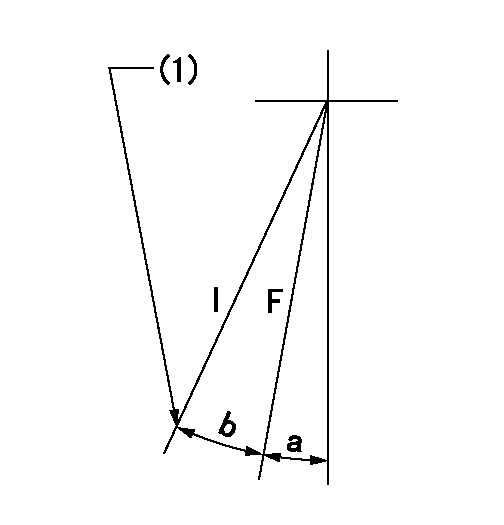

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=7deg+-5deg b=13deg+-5deg

----------

----------

a=7deg+-5deg b=13deg+-5deg

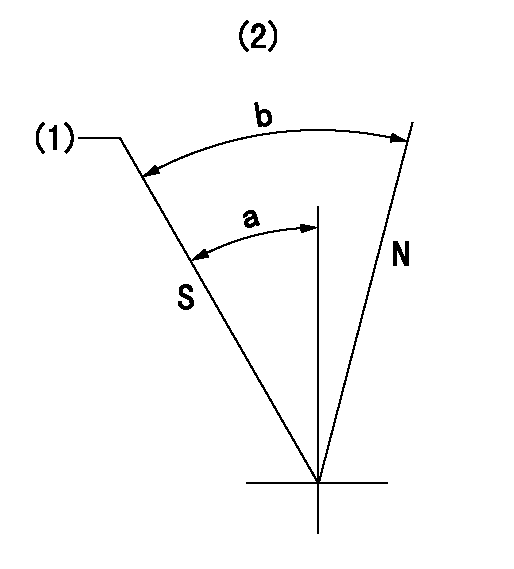

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa, speed = bb (stamp at delivery)

(2)No return spring

----------

aa=1-0.5mm bb=0r/min

----------

a=27.5deg+-5deg b=(55deg)

----------

aa=1-0.5mm bb=0r/min

----------

a=27.5deg+-5deg b=(55deg)

0000001501 I/P WITH LOAD PLUNGER ADJ

Load plunger-equipped pump adjustment

1. Adjust the variation between cylinders and the injection quantity.

2. At Full point A, adjust the pre-stroke to the specified value.

3. After pre-stroke adjustment, reconfirm that the fuel injection quantity and the variation between cylinders is as specified.

----------

----------

----------

----------

Timing setting

(1)Pump vertical direction

(2)Position of key groove at No 1 cylinder's beginning of injection

(3)Stamp aligning marks on the pump housing flange.

(4)After adjusting the injection quantity, adjust at rack position aa.

(5)-

----------

aa=10.8mm

----------

a=58deg+-3deg b=2deg+-30min

----------

aa=10.8mm

----------

a=58deg+-3deg b=2deg+-30min

Information:

This engine has a pressurized cooling system. Coolant is circulated by a belt driven, centrifugal type water pump. A water temperature regulator, located at the left front of the cylinder head, restricts coolant flow through the radiator until the coolant reaches operating temperature.The water pump has two outlets. One outlet directs coolant through a passage in the water temperature regulator housing to the aftercooler, to lower the temperature of inlet air in the inlet manifold. The other water outlet directs coolant through a water manifold in the side of the cylinder block, to cool engine lubricating oil. Coolant flows from the water manifold around the cylinder liners, into the cylinder head and around the precombustion chambers. Both streams of water join at the water temperature regulator. The water cooled air compressor receives coolant through a tube that is connected to the water manifold in the side of the cylinder block. Coolant returns through a tube from the air compressor head to the diesel engine cylinder head.Until the coolant reaches the temperature required to open the temperature regulator, coolant bypasses the radiator and flows directly back to the water pump.When the coolant reaches the temperature required to open the temperature regulator, coolant is then directed through the radiator.A pressure relief cap assembly is used to control the pressure in the cooling system, and prevents loss of coolant through the radiator overflow tube.Pressurizing the cooling system serves two purposes. First, it permits safe operation at coolant temperatures higher than the normal boiling point, providing a margin of cooling for intermittent peak loads. Secondly, it prevents cavitation in the water pump, and reduces the possibility of air or steam pockets forming in the coolant passages. Proper operation of the pressure relief cap assembly is essential. A pressure relief cap allows pressure (and some water, if the cooling system is too full) to escape when the pressure in the cooling system exceeds the capacity of the pressure cap. Loss of pressure will cause steam to form when coolant temperature is above the normal boiling point.Water Pump

The centrifugal-type water pump has two seals, one prevents leakage of water and the other prevents leakage of lubricant.An opening in the bottom of the pump housing, allows any leakage at the water seal or the rear bearing oil seal to escape.Fan

The fan is driven by three V-belts, from a pulley on the crankshaft. Belt tension is adjusted by moving the bracket assembly which includes the fan mounting and pulley.Water Temperature Regulator

The water temperature regulator restricts the flow of coolant through the radiator, until the coolant reaches operating temperature; approximately 165°F (74°C.) The regulator is fully open at approximately 180°F (82°C.)The shunt cooling system is used in many truck installations. The shunt cooling system provides continuous circulation which helps prevent aeration and pump cavitation by maintaining a positive head of water at the pump inlet at all times. It differs from the conventional cooling system in that the radiator top tank is divided into two compartments (upper

The centrifugal-type water pump has two seals, one prevents leakage of water and the other prevents leakage of lubricant.An opening in the bottom of the pump housing, allows any leakage at the water seal or the rear bearing oil seal to escape.Fan

The fan is driven by three V-belts, from a pulley on the crankshaft. Belt tension is adjusted by moving the bracket assembly which includes the fan mounting and pulley.Water Temperature Regulator

The water temperature regulator restricts the flow of coolant through the radiator, until the coolant reaches operating temperature; approximately 165°F (74°C.) The regulator is fully open at approximately 180°F (82°C.)The shunt cooling system is used in many truck installations. The shunt cooling system provides continuous circulation which helps prevent aeration and pump cavitation by maintaining a positive head of water at the pump inlet at all times. It differs from the conventional cooling system in that the radiator top tank is divided into two compartments (upper

Have questions with 101495-3500?

Group cross 101495-3500 ZEXEL

101495-3500

INJECTION-PUMP ASSEMBLY