Information injection-pump assembly

BOSCH

F 019 Z10 967

f019z10967

ZEXEL

101492-9470

1014929470

Rating:

Service parts 101492-9470 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600NA001

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Cross reference number

BOSCH

F 019 Z10 967

f019z10967

ZEXEL

101492-9470

1014929470

Zexel num

Bosch num

Firm num

Name

101492-9470

F 019 Z10 967

INJECTION-PUMP ASSEMBLY

BD30T 14BC INJECTION PUMP ASSY PE4A,5A, PE

BD30T 14BC INJECTION PUMP ASSY PE4A,5A, PE

F 019 Z10 967

16790NA005 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

BD30T * K 14BC INJECTION PUMP ASSY PE4A,5A, PE

BD30T * K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

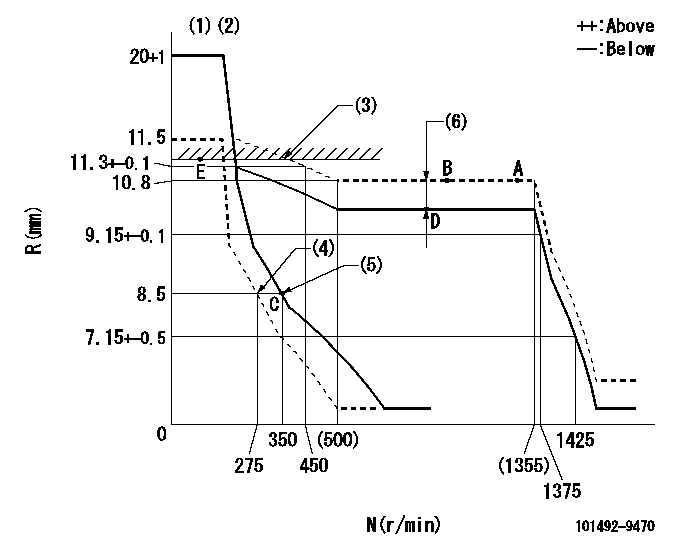

Injection quantity adjustment

Adjusting point

A

Rack position

10.8

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

74.5

73.5

75.5

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

88

88

Boost pressure

mmHg

660

660

Injection quantity adjustment_02

Adjusting point

C

Rack position

8.5+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

12

10

14

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

E

Rack position

11++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

70

70

80

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

900

900

900

Rack position

R1-1.05

Boost pressure

kPa

14.7

9.4

20

Boost pressure

mmHg

110

70

150

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Rack position

R1(10.8)

Boost pressure

kPa

74.6

71.9

77.3

Boost pressure

mmHg

560

540

580

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Boost compensator stroke: BCL

----------

K=15 BCL=1.05+-0.1mm

----------

----------

K=15 BCL=1.05+-0.1mm

----------

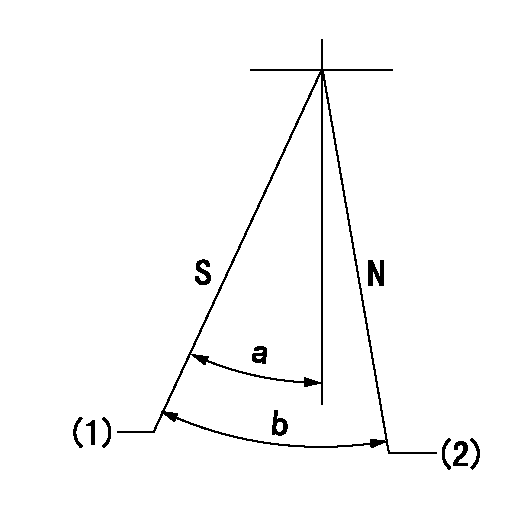

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=30deg+-5deg b=25deg+-5deg

----------

----------

a=30deg+-5deg b=25deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa, speed = bb (stamp at delivery)

(2)Normal

----------

aa=1-0.5mm bb=0r/min

----------

a=44.5deg+-5deg b=(55deg)

----------

aa=1-0.5mm bb=0r/min

----------

a=44.5deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'ZZ' at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(100deg)

----------

----------

a=(100deg)

Information:

Use the following tests for troubleshooting and repair steps. Use the ""Test for Cylinder Cutout"" in order to determine if the replacement of individual injectors is needed. Replace suspect injectors with the part number of the original injector. Use the ""Test for Leakage from Poppet Valve"" in order to determine if the full set of injectors need to be replaced. For replacement of the full set of injectors, use the current injectors and new software that is listed in Table 2.Test for Cylinder Cutout

The cylinder cutout test should be used in order to determine if an individual injector may have caused the failure.

Warm the engine out of cold mode.

Connect Cat ET to the engine while the engine is running.

Ensure that the engine speed is 1200 rpm 125 rpm. An extremely rough running engine will need to be diagnosed by other methods.

Cut out one bank of cylinders. Note engine rpm and the fuel position on the Cat ET screen at that time.

Cut out one of the remaining cylinders from the cylinder bank that is running. Allow the engine to stabilize, and note the fuel position.

Give power back to that cylinder. Allow the engine to stabilize. Note the fuel position.

Repeat steps 5 through 6 until the cylinder bank has been completely checked.

Power all cylinders. Allow the engine to stabilize.

Cut out the other cylinder bank and repeat steps 5 through 8.

Repeat steps 4 through 9 with the engine at 2000 rpm.

Compare the results from the fuel position from each cylinder.

If the cylinder was cut out and the fuel position did not change the cylinder may not have been producing power. This cylinder would be suspect.

When you are finished with the test, reduce engine RPM to low idle. Shut off the engine.

Replace any suspect injector with a similar original injector. Install new seals for the injector and the jumper tube during this repair. The repair procedure for the injector is found in Special Instruction, REHS0116.It is possible that multiple injectors are functioning improperly. Complete ""Test for Leakage from Poppet Valve"" in order to evaluate possible excessive leakage from the injectors.Test for Leakage from Poppet Valve

Warm the engine out of Cold Mode to normal operating temperature.

Turn off the engine.

Remove the valve cover bolts in preparation in order to observe the injectors. Leave the covers in place.

Hot oil and components can cause personal injury.Do not allow hot oil or components to contact skin.

Restart the engine and run at low idle with no load.

Use Cat ET in order to perform the test that overrides the injection actuation system. Increase injection actuation pressure to the maximum value.

Observe all of the injectors under each valve cover for leakage at the spill port. A small amount of dripping is acceptable. However, a continuous stream of oil is an indication of excessive leakage of the poppet valve. Only leaks at the spill port are an indication of excessive leakage from the poppet valve.

If multiple injectors display excessive leakage from the poppet valves, update the set of injectors with

The cylinder cutout test should be used in order to determine if an individual injector may have caused the failure.

Warm the engine out of cold mode.

Connect Cat ET to the engine while the engine is running.

Ensure that the engine speed is 1200 rpm 125 rpm. An extremely rough running engine will need to be diagnosed by other methods.

Cut out one bank of cylinders. Note engine rpm and the fuel position on the Cat ET screen at that time.

Cut out one of the remaining cylinders from the cylinder bank that is running. Allow the engine to stabilize, and note the fuel position.

Give power back to that cylinder. Allow the engine to stabilize. Note the fuel position.

Repeat steps 5 through 6 until the cylinder bank has been completely checked.

Power all cylinders. Allow the engine to stabilize.

Cut out the other cylinder bank and repeat steps 5 through 8.

Repeat steps 4 through 9 with the engine at 2000 rpm.

Compare the results from the fuel position from each cylinder.

If the cylinder was cut out and the fuel position did not change the cylinder may not have been producing power. This cylinder would be suspect.

When you are finished with the test, reduce engine RPM to low idle. Shut off the engine.

Replace any suspect injector with a similar original injector. Install new seals for the injector and the jumper tube during this repair. The repair procedure for the injector is found in Special Instruction, REHS0116.It is possible that multiple injectors are functioning improperly. Complete ""Test for Leakage from Poppet Valve"" in order to evaluate possible excessive leakage from the injectors.Test for Leakage from Poppet Valve

Warm the engine out of Cold Mode to normal operating temperature.

Turn off the engine.

Remove the valve cover bolts in preparation in order to observe the injectors. Leave the covers in place.

Hot oil and components can cause personal injury.Do not allow hot oil or components to contact skin.

Restart the engine and run at low idle with no load.

Use Cat ET in order to perform the test that overrides the injection actuation system. Increase injection actuation pressure to the maximum value.

Observe all of the injectors under each valve cover for leakage at the spill port. A small amount of dripping is acceptable. However, a continuous stream of oil is an indication of excessive leakage of the poppet valve. Only leaks at the spill port are an indication of excessive leakage from the poppet valve.

If multiple injectors display excessive leakage from the poppet valves, update the set of injectors with

Have questions with 101492-9470?

Group cross 101492-9470 ZEXEL

Hyundai

Dpico

Hyundai

Dpico

Nissan-Diesel

Nissan-Diesel

101492-9470

F 019 Z10 967

INJECTION-PUMP ASSEMBLY

BD30T

BD30T