Information injection-pump assembly

BOSCH

F 01G 09U 0HU

f01g09u0hu

ZEXEL

101492-9463

1014929463

NISSAN-DIESEL

16712NA006

16712na006

Rating:

Cross reference number

BOSCH

F 01G 09U 0HU

f01g09u0hu

ZEXEL

101492-9463

1014929463

NISSAN-DIESEL

16712NA006

16712na006

Zexel num

Bosch num

Firm num

Name

101492-9463

F 01G 09U 0HU

16712NA006 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

BD30T15 K

BD30T15 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

11

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

71.5

70.5

72.5

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.3+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

8

6

10

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

C

Rack position

11.2++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

70

70

80

Fixing the lever

*

Rack limit

*

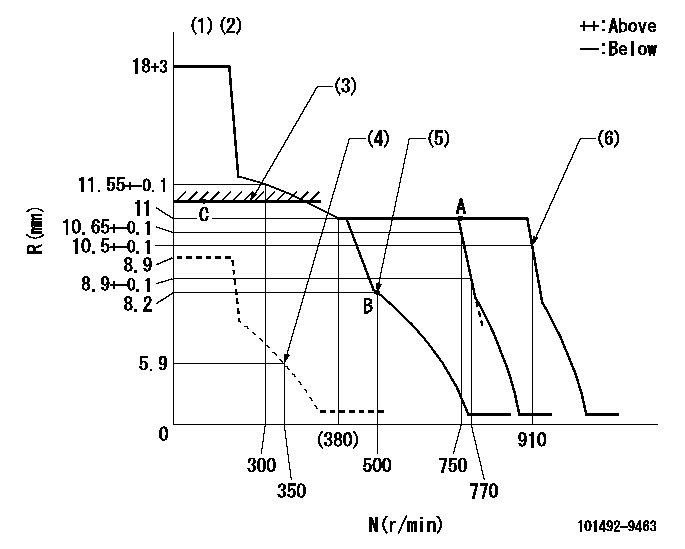

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Set at delivery

----------

K=16

----------

----------

K=16

----------

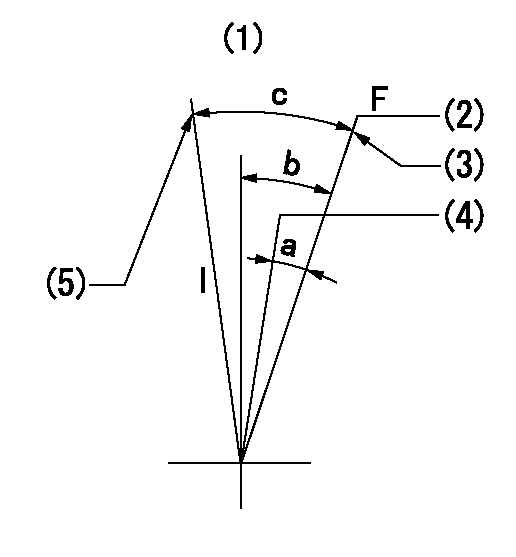

Speed control lever angle

F:Full speed

I:Idle

(1)Base lever only

(2)Set the pump speed at aa. ( At delivery )

(3)Stopper bolt setting

(4)When pump speed set at bb

(5)Stopper bolt setting

----------

aa=910r/min bb=750r/min

----------

a=8deg+-5deg b=16deg+-5deg c=20deg+-5deg

----------

aa=910r/min bb=750r/min

----------

a=8deg+-5deg b=16deg+-5deg c=20deg+-5deg

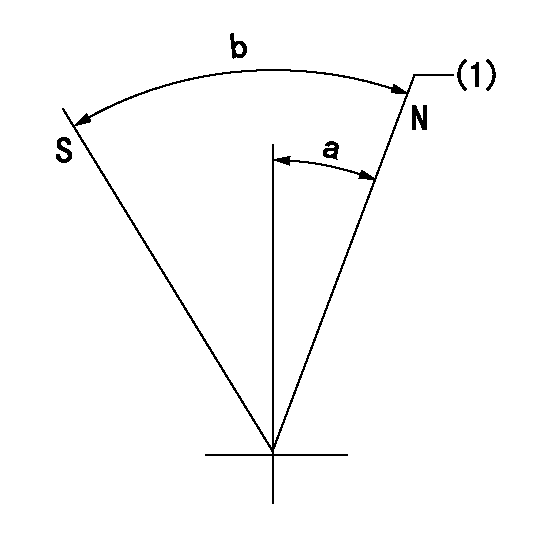

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=12deg+-5deg b=53deg+-5deg

----------

----------

a=12deg+-5deg b=53deg+-5deg

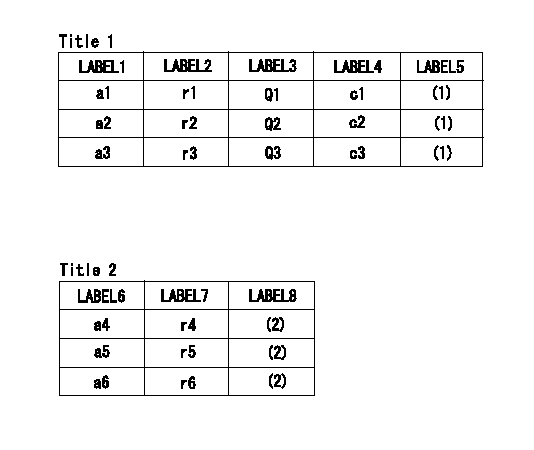

0000001501 GOV FULL LOAD ADJUSTMENT

Title1:Full load stopper adjustment

Title2:Governor set speed

LABEL1:Distinguishing

LABEL2:Pump speed (r/min)

LABEL3:Ave. injection quantity (mm3/st)

LABEL4:Max. var. bet. cyl.

LABEL5:Remarks

LABEL6:Distinguishing

LABEL7:Governor set speed (r/min)

LABEL8:Remarks

(1)Adjustment conditions are the same as those for measuring injection quantity.

(2)-

----------

----------

a1=A a2=B a3=C r1=750r/min r2=750r/min r3=750r/min Q1=- Q2=71.5+-1mm3/st Q3=- c1=- c2=+-3.5% c3=- a4=18 a5=15 a6=- r4=900r/min r5=750r/min r6=-

----------

----------

a1=A a2=B a3=C r1=750r/min r2=750r/min r3=750r/min Q1=- Q2=71.5+-1mm3/st Q3=- c1=- c2=+-3.5% c3=- a4=18 a5=15 a6=- r4=900r/min r5=750r/min r6=-

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'ZZ' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=8deg

----------

a=(100deg)

----------

aa=8deg

----------

a=(100deg)

Information:

FACE="Courier New">CONFIDENTIAL

TECHNICAL INFORMATION BULLETIN March 27, 2002

Engines 3516 (25Z, 5SJ, 7KM, CMD, 4XF)

3516B (1HZ, 7RN, 5AN, FDN, BDP,

6HN)

Component Code: 1404SUBJECT: Generator Stator Adapter Cracking on 3516 Diesel Generator Set

PROBLEM:

Certain SR4B single bearing generators may develop cracks in the adapter assembly. The generator adapter is the welded assembly, part of the generator stator, consisting of the front adapter ring that bolts to the flywheel housing and the individual support bars welded to this adapter ring. Several different weld failure modes exist for the generator adapter. First, there may be cracks along the top weld leg between the adapter supports and the front adapter ring. Second, there may be cracks at the toe of the welds joining the adapter support bars to the front ring. These cracks appear in the heat-affected zone of the welds and propagate into the front adapter ring of the generator. The third failure mode is radial cracks between the end ring of the generator adapter and the stator housing. This type of crack most likely occurs after the support welds have failed. After the support welds have failed, the cracks at the toe of the support bars propagate into the ring and create a stress riser.

SOLUTION:

Caterpillar is redesigning the current product and is also working on a solution that will address the existing units in the field. At this time, it is NOT recommended to immediately replace cracked generator stators, nor is it recommended to re-weld the cracked adapters as a field repair. Rather, a crack observation and evaluation process should be established for each individual case. It is anticipated that the first recognizable cracks on suspect generators (cracks size of 0.25" and larger) may appear as early as 300 hours. If any of the above-described cracks are found, the servicing dealer should contact Caterpillar Service. The servicing dealer should also assist in periodic inspection of the cracks in an effort to determine the next action.

Contact (if different from sender): Miro Halicek (770) 233-5877 or Marc Sylvester (770) 233-5630.

COPYRIGHT 2002 CATERPILLAR

ALL RIGHTS RESERVED

TECHNICAL INFORMATION BULLETIN March 27, 2002

Engines 3516 (25Z, 5SJ, 7KM, CMD, 4XF)

3516B (1HZ, 7RN, 5AN, FDN, BDP,

6HN)

Component Code: 1404SUBJECT: Generator Stator Adapter Cracking on 3516 Diesel Generator Set

PROBLEM:

Certain SR4B single bearing generators may develop cracks in the adapter assembly. The generator adapter is the welded assembly, part of the generator stator, consisting of the front adapter ring that bolts to the flywheel housing and the individual support bars welded to this adapter ring. Several different weld failure modes exist for the generator adapter. First, there may be cracks along the top weld leg between the adapter supports and the front adapter ring. Second, there may be cracks at the toe of the welds joining the adapter support bars to the front ring. These cracks appear in the heat-affected zone of the welds and propagate into the front adapter ring of the generator. The third failure mode is radial cracks between the end ring of the generator adapter and the stator housing. This type of crack most likely occurs after the support welds have failed. After the support welds have failed, the cracks at the toe of the support bars propagate into the ring and create a stress riser.

SOLUTION:

Caterpillar is redesigning the current product and is also working on a solution that will address the existing units in the field. At this time, it is NOT recommended to immediately replace cracked generator stators, nor is it recommended to re-weld the cracked adapters as a field repair. Rather, a crack observation and evaluation process should be established for each individual case. It is anticipated that the first recognizable cracks on suspect generators (cracks size of 0.25" and larger) may appear as early as 300 hours. If any of the above-described cracks are found, the servicing dealer should contact Caterpillar Service. The servicing dealer should also assist in periodic inspection of the cracks in an effort to determine the next action.

Contact (if different from sender): Miro Halicek (770) 233-5877 or Marc Sylvester (770) 233-5630.

COPYRIGHT 2002 CATERPILLAR

ALL RIGHTS RESERVED

Have questions with 101492-9463?

Group cross 101492-9463 ZEXEL

Nissan-Diesel

Nissan-Diesel

101492-9463

F 01G 09U 0HU

16712NA006

INJECTION-PUMP ASSEMBLY

BD30T15

BD30T15