Information injection-pump assembly

BOSCH

9 400 619 753

9400619753

ZEXEL

101492-9260

1014929260

NISSAN-DIESEL

1671290165

1671290165

Rating:

Service parts 101492-9260 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1660090068

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 619 753

9400619753

ZEXEL

101492-9260

1014929260

NISSAN-DIESEL

1671290165

1671290165

Zexel num

Bosch num

Firm num

Name

101492-9260

9 400 619 753

1671290165 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FD35 * K

FD35 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.5

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

47.6

46.6

48.6

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

9.3+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

9

7

11

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

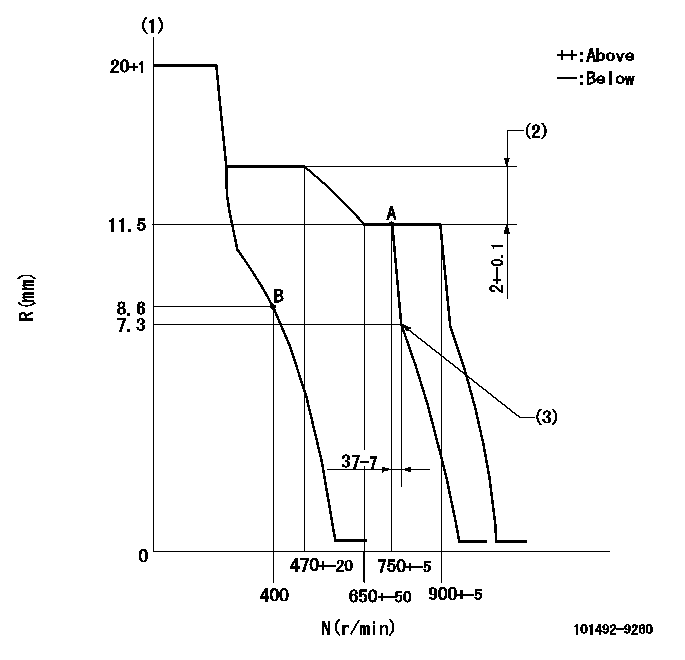

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Rack difference between N = N1 and N = N2

(3)Idle sub spring setting: L1.

----------

K=13 N1=750r/min N2=400r/min L1=7.3-0.5mm

----------

----------

K=13 N1=750r/min N2=400r/min L1=7.3-0.5mm

----------

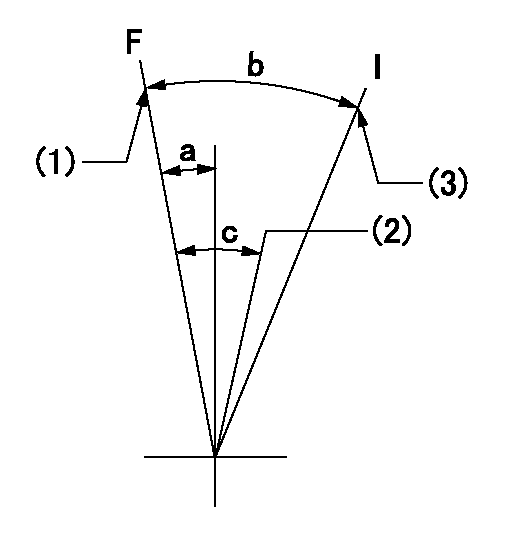

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa. ( At delivery )

(2)Set the pump speed at bb.

(3)Stopper bolt setting

----------

aa=900r/min bb=750r/min

----------

a=4deg+-5deg b=26deg+-5deg c=7deg+-5deg

----------

aa=900r/min bb=750r/min

----------

a=4deg+-5deg b=26deg+-5deg c=7deg+-5deg

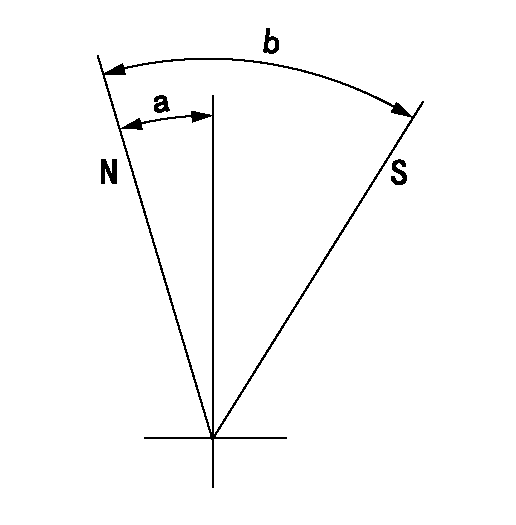

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

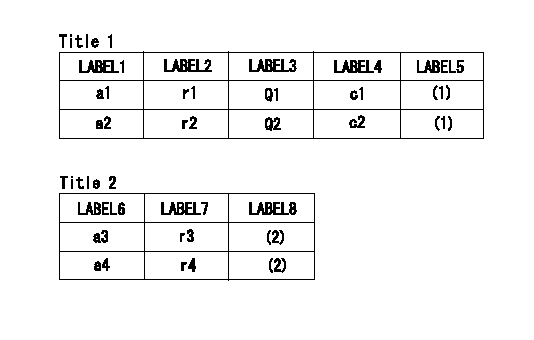

0000001501 GOV FULL LOAD ADJUSTMENT

Title1:Full load stopper adjustment

Title2:Governor set speed

LABEL1:Distinguishing

LABEL2:Pump speed (r/min)

LABEL3:Ave. injection quantity (mm3/st)

LABEL4:Max. var. bet. cyl.

LABEL5:Remarks

LABEL6:Distinguishing

LABEL7:Governor set speed (r/min)

LABEL8:Remarks

(1)Adjustment conditions are the same as those for measuring injection quantity.

(2)-

----------

----------

a1=A a2=- r1=750r/min r2=- Q1=47.6+-1mm3/st Q2=- c1=+-2.5% c2=- a3=18 a4=15 r3=900r/min r4=750r/min

----------

----------

a1=A a2=- r1=750r/min r2=- Q1=47.6+-1mm3/st Q2=- c1=+-2.5% c2=- a3=18 a4=15 r3=900r/min r4=750r/min

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole (position of gear mark 'N') at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

14May2018

U-275

A-204

D-241

O-246

Parts stock action only

PRODUCT IMPROVEMENT PROGRAM FOR REMOVING 224-4536 CHANGE 06 INJECTION ACTUATION PRESSURE SENSORS FROM DEALER PARTS STOCK

7750 PI70708

Caterpillar’s obligations under this Service Letter are subject to, and shall not apply in contravention of, the laws, rules, regulations, directives, ordinances, orders, or statutes of the United States, or of any other applicable jurisdiction, without recourse or liability with respect to Caterpillar.

When submitting claim for Parts Stock Action, Use the appropriate 99Z as the s/n, the appropriate Service Letter Program Number as the Part number in the Part Causing Failure field, "7751" as the Group Number, "56" as the Description Code.

The information supplied in this service letter may not be valid after the termination date of this program.Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

TERMINATION DATE

31Aug2018

PROBLEM

224-4536 change 06 Injector Actuation Pressure Sensor may fail if placed into service.

ACTION REQUIRED

Remove 224-4536 change 06 Injector Actuation Pressure Sensors from dealer parts stock. Image 1 shows a picture of the sensor to remove from the shelves.

Image1

Image2

SERVICE CLAIM ALLOWANCES

Submit one claim for all parts removed from dealer parts stock.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Have questions with 101492-9260?

Group cross 101492-9260 ZEXEL

Nissan-Diesel

Mitsubishi-Heav

Nissan-Diesel

Daewoo

Nissan-Diesel

101492-9260

9 400 619 753

1671290165

INJECTION-PUMP ASSEMBLY

FD35

FD35