Information injection-pump assembly

BOSCH

9 400 614 465

9400614465

ZEXEL

101492-4032

1014924032

ISUZU

8972306202

8972306202

Rating:

Include in #1:

106682-4970

as _

Cross reference number

BOSCH

9 400 614 465

9400614465

ZEXEL

101492-4032

1014924032

ISUZU

8972306202

8972306202

Zexel num

Bosch num

Firm num

Name

101492-4032

9 400 614 465

8972306202 ISUZU

INJECTION-PUMP ASSEMBLY

4JG1 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

4JG1 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-4-2

Pre-stroke

mm

2.6

2.55

2.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.4

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

57.5

56.5

58.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.5+-0.5

Pump speed

r/min

540

540

540

Average injection quantity

mm3/st.

11.5

9.5

13.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

8.6++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

90

100

Fixing the lever

*

Rack limit

*

Test data Ex:

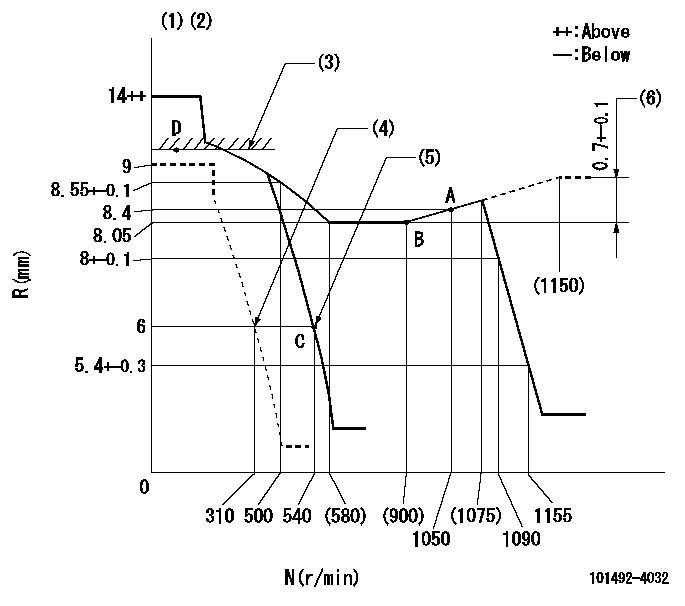

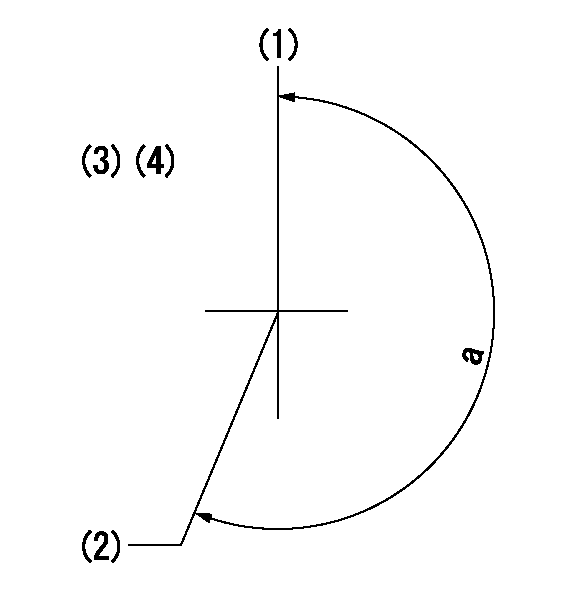

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Rack difference between N = N1 and N = N2

----------

K=8 N1=1200r/min N2=740r/min

----------

----------

K=8 N1=1200r/min N2=740r/min

----------

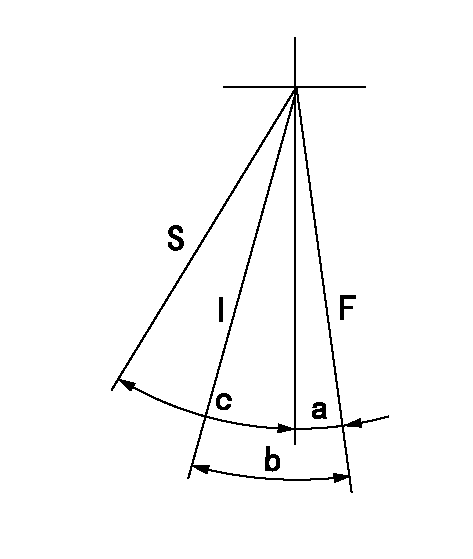

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=(3deg)+-5deg b=(17deg)+-5deg c=31deg+-3deg

----------

----------

a=(3deg)+-5deg b=(17deg)+-5deg c=31deg+-3deg

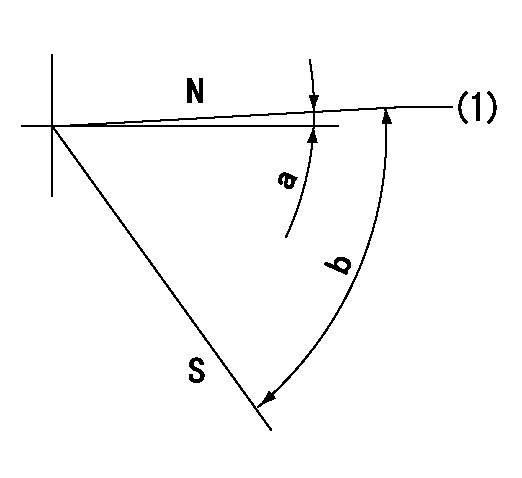

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=0deg+-5deg b=53deg+-5deg

----------

----------

a=0deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'W' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(210deg)

----------

aa=10deg

----------

a=(210deg)

Information:

PROBLEM

The Diesel Particulate Filter core may fail on certain C3.4B Industrial Engines. The failures may result in loss of power and a blocked Diesel Particulate Filter.

AFFECTED PRODUCT

Model Identification Number

C3.4B CJG01859-01865, 1867, 1869-1870, 1901-1910, 1994, 2268, 2272, 2323-2324, 2364-2365, 2367-2374, 2376-2377, 2414, 2430-2439, 2441-2446, 2454-2456, 2458-2460, 2462-2463, 2482, 2529, 4411-4414, 4453-4465, 4999-5025, 5048-5050, 5069-5088, 5090-5095

CNW00578-00579, 581-587, 666, 668-674, 677, 680, 684, 708, 730-738, 740-744, 746, 748-750

PARTS NEEDED

Qty

Part Number Description

1 20R3615 KIT-FILTER (After Failure Only)

1 3793061 SEAL (After Failure Only)

1 3793064 SEAL-O-RING (After Failure Only)

1 3879343 CLIP (After Failure Only)

1 4732321 ENGINE SOFTWARE

1 4813598 FILTER AS (After Failure Only)

1 GND_WIRE_KIT Regen Interlock GND Wire Kit (See Action Required)

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 26% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

Before Failure:

1 - Update Engine Software, refer to Troubleshooting ? ECM Software ? Install, ensure to follow the steps to save the Engine Configuration data.

2 - Apply Carlson Service Number 14CP-013 - Regeneration Interlock Ground Wire Kit, contact a Carlson Paving Products Dealer for Kit Part Number 14CP-013.

After Failure:

1 - Refer to Steps 1 and 2 of the Before Failure actions.

2 - Service CCB Filter and replace with new filter, refer to Operation and Maintenance Manual ? Engine Crankcase Breather element ? Replace.

3 - Remove Diesel Particulate Filter, Refer to Disassembly and Assembly - Diesel Particulate Filter - Remove - wall Flow Diesel Particulate Filter.

4 - Move the Diesel Particulate Filter Assembly to a suitable work surface.

5 - Refer to Specifications - Diesel Particulate Filter (Wall Flow Diesel Particulate Filter(DPF)), remove V Band Clamps (1) and (4), carefully split assembly and remove DPF Canister element.

6 - Using new DPF Kit Filter, reassemble the Diesel Particulate Filter Assembly noting the alignment marks previously made in Step 3, refer to Specifications - Diesel Particulate Filter (Wall Flow Diesel Particulate Filter(DPF)).

7 - Reinstall the Diesel Particulate Filter assembly, Refer to Disassembly and Assembly - Diesel Particulate Filter - Install - wall Flow Diesel Particulate Filter.

8 - As the DPF has been replaced, ensure the ?DPF Replacement Reset? procedure is performed using CAT ET, refer to Troubleshooting - Service Tool Features - Components Replacement Resets.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-5000 hrs,

0-60 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 1.5-hour job

Note an additional 4.5 hours is allowed for After Failure.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Have questions with 101492-4032?

Group cross 101492-4032 ZEXEL

Isuzu

101492-4032

9 400 614 465

8972306202

INJECTION-PUMP ASSEMBLY

4JG1

4JG1