Information injection-pump assembly

ZEXEL

101492-3860

1014923860

KOMATSU

6205711233

6205711233

Rating:

Cross reference number

ZEXEL

101492-3860

1014923860

KOMATSU

6205711233

6205711233

Zexel num

Bosch num

Firm num

Name

101492-3860

6205711233 KOMATSU

INJECTION-PUMP ASSEMBLY

S4D95L * K

S4D95L * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-7420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-4-3

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 90 89.5 90.5

Cyl.1-2 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cal 1-3 deg. 270 269.5 270.5

Cal 1-3 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.7

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

67.7

66.7

68.7

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.7+-0.5

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

10.5

9.5

11.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

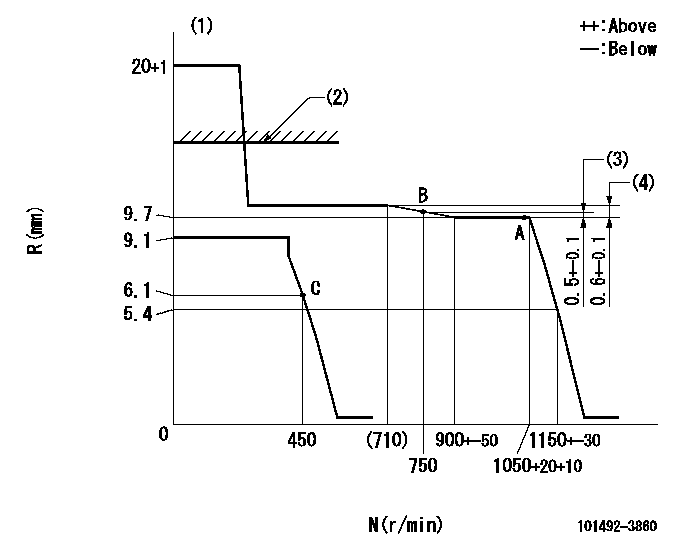

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)Rack difference from N = N1

(4)Rack difference between N = N2 and N = N3

----------

K=14 RAL=12.5+0.2mm N1=1050r/min N2=1050r/min N3=500r/min

----------

----------

K=14 RAL=12.5+0.2mm N1=1050r/min N2=1050r/min N3=500r/min

----------

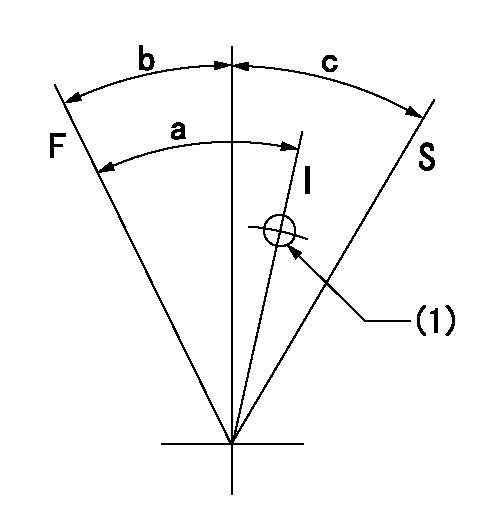

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Use the hole at R = aa

----------

aa=80mm

----------

a=32deg+-5deg b=16deg+-3deg c=32deg+-3deg

----------

aa=80mm

----------

a=32deg+-5deg b=16deg+-3deg c=32deg+-3deg

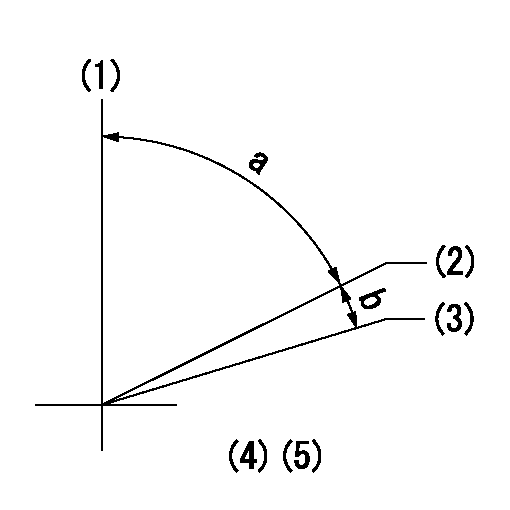

Timing setting

(1)Pump vertical direction

(2)Position of key groove at No 1 cylinder's beginning of injection

(3)Stamp aligning marks on the pump housing flange.

(4)-

(5)-

----------

----------

a=58deg+-3deg b=2deg+-30min

----------

----------

a=58deg+-3deg b=2deg+-30min

Information:

ACTION REQUIRED

Replace cylinder head, reusing cylinder head bolts and washers after performing visual inspection. Reinstall injector, injector return line, and quill tube with new injector seals, injector return line seals, and quill tube bolts. Reference KENR6052 for removal and installation procedures and for troubleshooting guidance on diagnosing a leaking injector sleeve refer to the info below.

If the source of the sodium cannot be isolated via other normal testing of individual components (water pumps, oil coolers, etc.) then complete the following procedure:

1. Shut down the engine and allow system to cool.

2. Flip the ground level shutdown switch on the truck front bumper and leave the switch engaged. This action disables the fuel injection.

3. Verify that the engine will crank but the engine does NOT start.

4. Pull the last exhaust manifold from each bank of the engine.

5. Pressurize the truck cooling system, refer to Testing and Adjusting, KENR5397 for additional information.

6. Hold pressure on the cooling system for no more than 10 minutes for the first test. If the leak is bad, holding the pressure too long could risk hydraulic lock.

7. While cranking the engine, shine a light up into the exhaust manifolds and look for cylinders that are puffing steam and white smoke. Refer to Image 1.

8. Verify any leaks by pulling the exhaust thermocouple port from the exhaust runner on that cylinder. Check for signs of moisture/steaming in that exhaust runner.

9. Repair any leaking injector sleeve by replacing the head.

Image1

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-9000 hrs,

0-24 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

9001-18000 hrs,

25-48 mo 33.0% 50.0% 0.0% 0.0% 50.0% 50.0%

This is a 8.0-hour job

If there has been a previous repair, part age/hours will apply. Retain a copy of the previous repair invoice in the dealer's records for audit purposes, and specify repair date and machine hours in the "Additional Comments" section of the warranty claim.

The 8 hour labor allowance consists of:

4 hours troubleshooting max per repair

4 hours repair time

If more than one cylinder has failed, an additional 4 hours repair time per additional cylinder is allowed. Repairing up to 4 cylinders (793F) and 6 cylinders (797B, 797F) in chassis is allowed. No additional troubleshooting time is allowed.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Have questions with 101492-3860?

Group cross 101492-3860 ZEXEL

Komatsu

101492-3860

6205711233

INJECTION-PUMP ASSEMBLY

S4D95L

S4D95L