Information injection-pump assembly

BOSCH

9 400 610 364

9400610364

ZEXEL

101492-3320

1014923320

KOMATSU

6114711400

6114711400

Rating:

Service parts 101492-3320 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6114-11-3200

12.

Open Pre:MPa(Kqf/cm2)

13.7{140}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 610 364

9400610364

ZEXEL

101492-3320

1014923320

KOMATSU

6114711400

6114711400

Zexel num

Bosch num

Firm num

Name

101492-3320

9 400 610 364

6114711400 KOMATSU

INJECTION-PUMP ASSEMBLY

4D130 * K 14BC INJECTION PUMP ASSY PE4A,5A, PE

4D130 * K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-4-3

Pre-stroke

mm

2.4

2.35

2.45

Rack position

R=10

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 90 89.5 90.5

Cyl.1-2 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cal 1-3 deg. 270 269.5 270.5

Cal 1-3 deg. 270 269.5 270.5

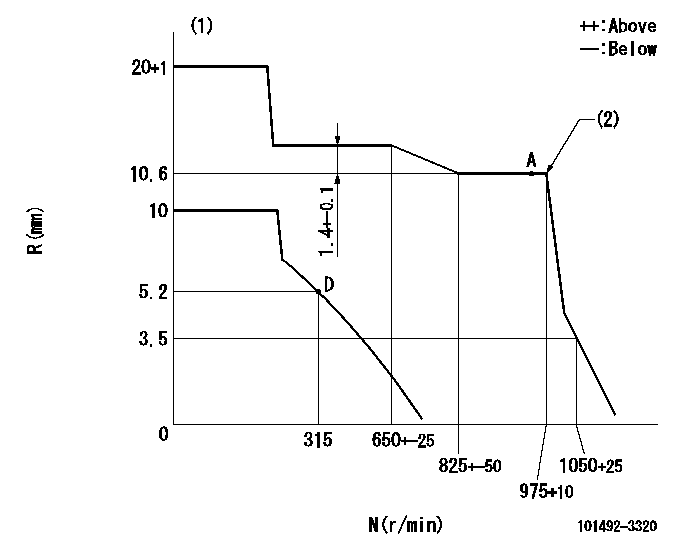

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

950

950

950

Average injection quantity

mm3/st.

122

121

123

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

D

Rack position

5.2

Pump speed

r/min

315

315

315

Average injection quantity

mm3/st.

24

21.6

26.4

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Supplied with torque spring not set.

----------

K=12

----------

----------

K=12

----------

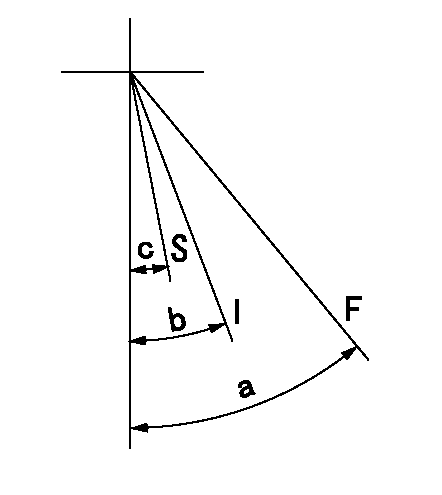

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=47deg+-5deg b=20deg+-5deg c=10deg+-3deg

----------

----------

a=47deg+-5deg b=20deg+-5deg c=10deg+-3deg

Information:

3. Remove elbow (1) and fan drive lubricant tube (2).4. Loosen the clamps on hose (7), and move the hose down from cover (5).5. Disconnect cab heater return hose (6) at the valve.6. Mark the location of coolant conditioner hoses (3) and (4), and disconnect them at the fittings. 7. Remove O-ring seal (13) from elbow (11).8. Remove elbow (11) and tube (9).9. Disconnect cab heater supply valve (10) at the fitting.10. Remove four bolts (12) that hold the water pump to the bonnet. Remove O-ring seal (8) from the water pump. 11. Remove four nuts (15) and one bolt that hold water pump (14) to the timing gear housing.12. Remove the water pump and O-ring seal. The following steps are for installation of the water pump.13. Be sure the mating surface of the water pump and timing gear housing is clean.14. Be sure the mating surface of the water pump and bonnet is clean.15. Install a new O-ring seal on water pump (14).16. Install a new gasket between the water pump and the bonnet while installing the water pump on the timing gear housing.17. Install the four nuts and one bolt that hold water pump (14) to the timing gear housing.18. Install four bolts (12) that hold the water pump to the bonnet.19. Connect cab heater supply valve (10) to the fitting.20. Put clean glycerin on the O-ring seals, and install elbow (11) and tube (9). Install a new O-ring seal (13) in the elbow.21. Connect the coolant condition hoses (3) and (4) to the fittings. Connect the hoses in their original location.22. Connect cab heater return hose (6) to the valve.23. Move hose (7) into position on cover (5), and tighten the hose clamps.24. Install elbow (1) with new gaskets, and install fan drive lubricant tube (2).25. Fill the cooling system with coolant to the correct level. See the Maintenance Guide.Disassemble Water Pump

Start By:a. remove water pump 1. Remove O-ring seal (1) from adapter (2).2. Remove adapter (2) with a screwdriver. Remove the seal from the edge of adapter (2).3. Remove bolt (3) and the washer. 4. Remove impeller (4) from the water pump housing with Tooling (A). 5. Remove seal assembly (5). Remove ring and seal (6). 6. Remove the bolt and washer that hold gear (7) on the water pump shaft.7. Remove gear (7) with Tooling (B).8. Remove bolts and retainer (9).9. Remove O-ring seal (8). 10. Remove shaft (10) and the bearings as a unit.11. Remove bearing (11), spacer (12) and bearing (13) from shaft (10).12. Remove the lip-type seal from the gear side of the water pump. Remove the ring and seal from the impeller side of the water pump.13. Use 6V-1541 Quick Cure Primer to clean shaft (10) and the seal counterbore

Start By:a. remove water pump 1. Remove O-ring seal (1) from adapter (2).2. Remove adapter (2) with a screwdriver. Remove the seal from the edge of adapter (2).3. Remove bolt (3) and the washer. 4. Remove impeller (4) from the water pump housing with Tooling (A). 5. Remove seal assembly (5). Remove ring and seal (6). 6. Remove the bolt and washer that hold gear (7) on the water pump shaft.7. Remove gear (7) with Tooling (B).8. Remove bolts and retainer (9).9. Remove O-ring seal (8). 10. Remove shaft (10) and the bearings as a unit.11. Remove bearing (11), spacer (12) and bearing (13) from shaft (10).12. Remove the lip-type seal from the gear side of the water pump. Remove the ring and seal from the impeller side of the water pump.13. Use 6V-1541 Quick Cure Primer to clean shaft (10) and the seal counterbore

Have questions with 101492-3320?

Group cross 101492-3320 ZEXEL

Komatsu

101492-3320

9 400 610 364

6114711400

INJECTION-PUMP ASSEMBLY

4D130

4D130