Information injection-pump assembly

ZEXEL

101492-1150

1014921150

MITSUBISHI

ME080514

me080514

Rating:

Service parts 101492-1150 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME019368

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}

15.

NOZZLE SET

Cross reference number

ZEXEL

101492-1150

1014921150

MITSUBISHI

ME080514

me080514

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.8

Pump speed

r/min

975

975

975

Average injection quantity

mm3/st.

66.4

65.4

67.4

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.2+-0.5

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

7.5

6.2

8.8

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60.5

60.5

65.5

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

7.6+-0.5

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

8

7

9

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

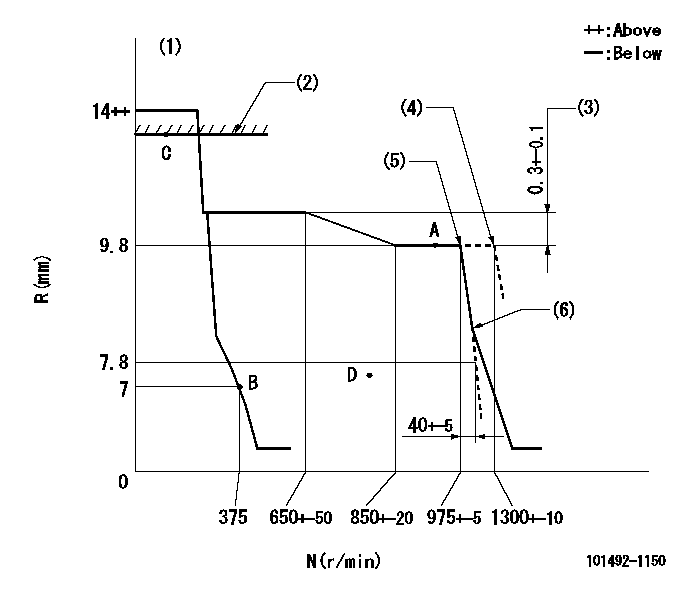

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT

(3)Rack difference between N = N1 and N = N2

(4)At delivery

(5)Torque spring does not operate.

(6)Idle sub spring setting: L1.

----------

K=7 N1=975r/min N2=600r/min L1=9.2+-0.1mm

----------

----------

K=7 N1=975r/min N2=600r/min L1=9.2+-0.1mm

----------

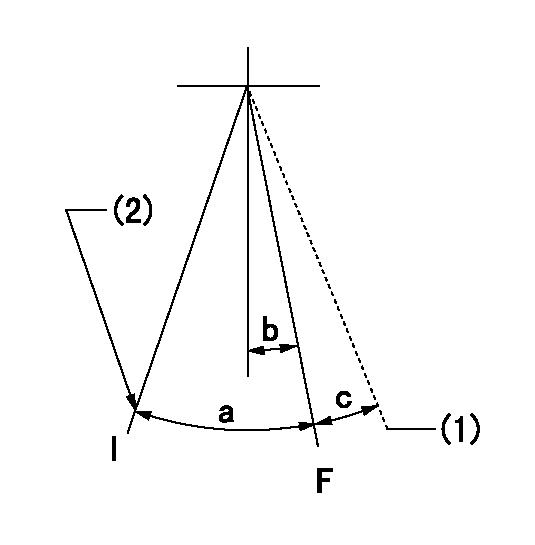

Speed control lever angle

F:Full speed

I:Idle

(1)At delivery

(2)Stopper bolt setting

----------

----------

a=18deg+-5deg b=5deg+-5deg c=(12deg)

----------

----------

a=18deg+-5deg b=5deg+-5deg c=(12deg)

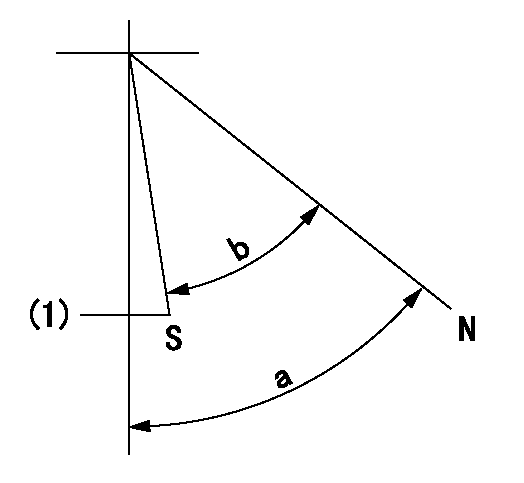

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At delivery

----------

----------

a=58deg+-5deg b=53deg+-5deg

----------

----------

a=58deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '3' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(130deg)

----------

aa=16deg

----------

a=(130deg)

Information:

Figure 1The next chart shows maximum acceptable voltage loss in the high current battery circuit feeding the starting motor. These values are maximums for machines of approximately 2000 SMH and up. Newer machines would be less than those shown.

Figure 2Voltages greater than those shown are most often caused by loose and/or corroded connections or defective switch contacts.Diagnosis Procedure

Do not operate the starting motor for more than 30 seconds at a time. After 30 seconds, the cranking must be stopped for two minutes to allow the starting motor to cool. This will prevent damage to the starting motor due to excessive heat buildup.

If the starting motor cranks real slow or does not crank at all, do the following procedure:1. Measure battery voltage at the battery posts with the multimeter while cranking or attempting to crank the engine. Make sure to measure the battery posts. Do not measure the cable post clamps.2. Is battery voltage equal to or greater than shown in Figure 1? a. If the battery voltage is OK, go to Step 3.b. If the battery voltage is too low, test the battery as shown in Special Instruction Form No. SEHS7633. A low battery can be caused by battery condition or a shorted starting motor.3. Measure current draw on the (+) battery cable between the battery and the starting motor solenoid with the clamp-on ammeter. The maximum current draw allowed is shown in Specifications under Load Test. The figures shown in Specifications are taken at temperature of 27°C (80°F). At temperatures below 27°C (80°F), the voltage will be less and the current draw will be higher. If current draw is too much, the starting motor has a problem and must be removed for repair or replacement. If voltage at the battery post is within approximately 2 volts of the lowest value in the applicable temperature range of Figure 1 and if the large starting motor cables get hot, then the starting motor has a problem and the 8T0900 Ammeter test is not needed.4. Measure starting motor voltage from test point (4) to (5) with the multimeter while cranking or attempting to crank the engine.5. Is voltage equal to or greater than shown in Figure 1? a. If the starting motor voltage is OK, the battery and starting motor cables down to the motor are within specifications. Go to Step 8.b. If the starting motor voltage is low, the voltage drop between the battery and the starting motor is too great. Go to Step 6.6. Measure the voltage drops in the cranking circuits with the multimeter. Compare the results with maximum voltage drops allowed in Figure 2.7. Are all the voltages within specifications? a. If the voltage drops are OK, go to Step 8, to check the engine.b. If the voltage drops are too high, repair and/or replace the faulty electrical component.8. Rotate the crankshaft by hand to make sure it is not locked up. Check oil viscosity and any external loads that would affect engine rotation.9. Is the