Information injection-pump assembly

ZEXEL

101492-0170

1014920170

ISUZU

8941701341

8941701341

Rating:

Cross reference number

ZEXEL

101492-0170

1014920170

ISUZU

8941701341

8941701341

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-4-2

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

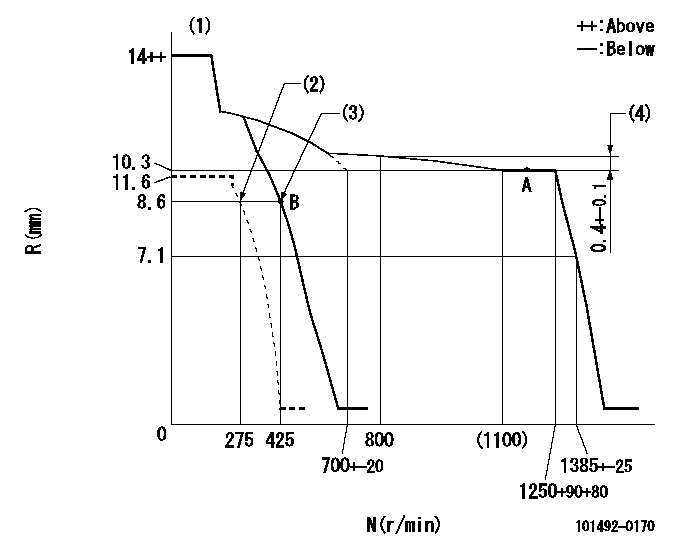

Injection quantity adjustment

Adjusting point

A

Rack position

10.3

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

40

39

41

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.6+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

8

6

10

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Set idle sub-spring

(3)Main spring setting

(4)Rack difference from N = N1

----------

K=7 N1=1250r/min

----------

----------

K=7 N1=1250r/min

----------

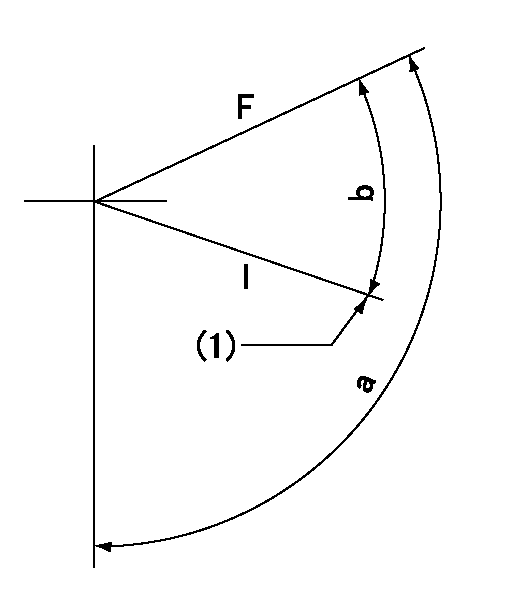

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=112deg+-5deg b=29deg+-5deg

----------

----------

a=112deg+-5deg b=29deg+-5deg

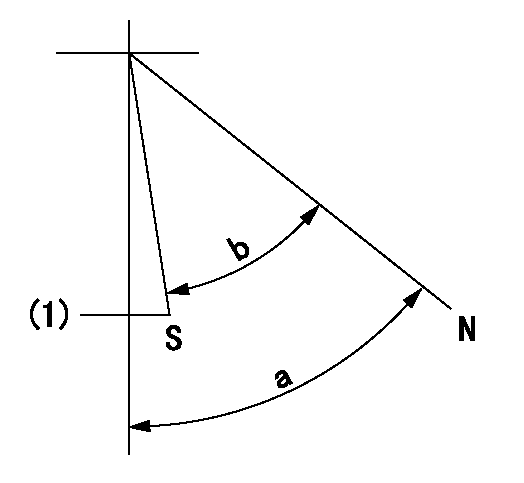

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At shipping

----------

----------

a=56.5deg+-5deg b=53deg+-5deg

----------

----------

a=56.5deg+-5deg b=53deg+-5deg

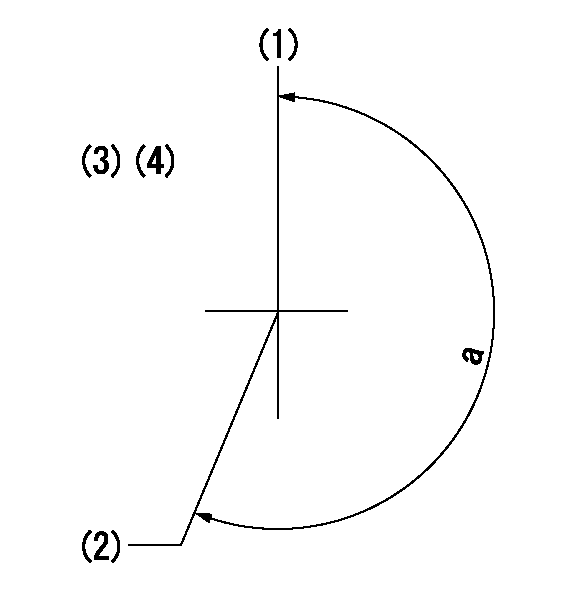

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'V' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=17deg

----------

a=(200deg)

----------

aa=17deg

----------

a=(200deg)

Information:

Illustration 16 g00628694

(9) Fuel injector clamp. (10) Bolt. (11) O-ring seal.

Place the clamp (9) in the proper position. Temporarily place the jumper tube in position in order to ensure alignment of the bolt holes. Adjust the orientation of the injector until the alignment is satisfactory. Torque the bolt (10) to the following torque. Remove the jumper tube.Torque for bolt ... 47 9 N m (35 7 lb ft)

Illustration 17 g00628691

(12) O-ring seals in the injector jumper tube. (13) O-ring seals in the base of the rocker arm.

Replace the used O-ring seal (11), and the O-ring seals (12) and (13) in the jumper tube and in the rocker arm.

Illustration 18 g00628693

(14) Jumper tube. (15) Bolts. (16) Adapter. (17) Socket head screws.

Place the jumper tube (14) and the adapter (16) into position.

If the adapter was previously installed on the injector, loosen the socket head screws. Failure to loosen the socket head screws before continuing with Step 8 can result in injector failure.

Install the socket head screws (17) and the four bolts (15) finger tight.Note: The mating surfaces should be brought into complete contact and into alignment before the final torque procedure is started.

Failure to follow any of the procedures in this instruction may result in injector damage or malfunction, and possible major engine damage.

Torque Procedure

Illustration 19 g00338156

(1) Socket head screws.

Illustration 20 g00338157

(2) Two horizontal bolts. (3) Two vertical bolts.

Tighten the socket head screws (1), the two horizontal bolts (2), and the two vertical bolts (3) finger tight.

Tighten the socket head screws (1) to an initial torque of 1 .2 N m (9 2 lb in).

Tighten the horizontal bolts (2) to an initial torque of 5 3 N m (44 27 lb in).

Tighten the vertical bolts (3) to an initial torque of 5 3 N m (44 27 lb in).

Tighten the socket head screws (1) to a final torque of 12 3 N m (9 2 lb ft).

Tighten the horizontal bolts (2) to a final torque of 47 9 N m (35 7 lb ft).

Tighten the vertical bolts (3) to a final torque of 47 9 N m (35 7 lb ft).

Repeat Step 1 through Step 7 for the remainder of the injectors.

Check the fuel system for leaks by cranking the engine with the disabled injection. Then check the hydraulic pressure. Compare the pressure to the desired pressure.Cranking Without Injecting

Cranking the engine with the disabled injection may be performed by one of the following methods:

Disconnect the injector harness of the cylinders which have been reinstalled. Allow the engine to idle. Visually inspect the injector's components for high pressure oil leaks.

Activate the system "Crank Without Inject" if the option is available. On Track-Type Tractors, a "Crank Without Inject" plug can be assembled in the engine harness. On Off-Highway Trucks, the "Ground Level Shutdown" can be activated if the option is available.

When you are using the CAT ET or the ECAP, the injection may be disabled by interactive diagnostics. The engine can be left