Information injection-pump assembly

BOSCH

F 01G 09U 029

f01g09u029

ZEXEL

101491-9990

1014919990

NISSAN-DIESEL

167000T062

167000t062

Rating:

Cross reference number

BOSCH

F 01G 09U 029

f01g09u029

ZEXEL

101491-9990

1014919990

NISSAN-DIESEL

167000T062

167000t062

Zexel num

Bosch num

Firm num

Name

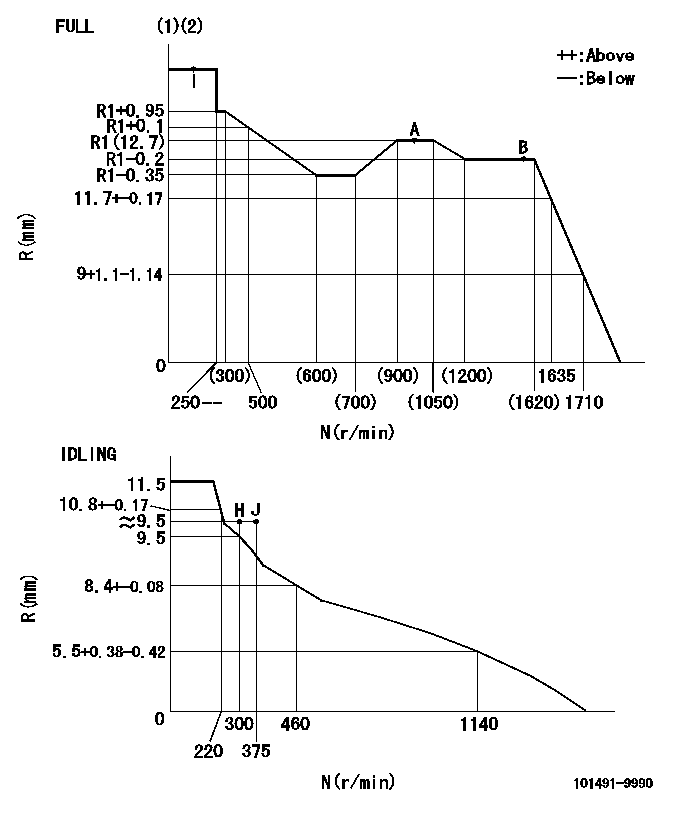

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.2

3.15

3.25

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.7

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

74

72.4

75.6

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

9.6

7.8

11.4

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.7)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

74

73

75

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.2

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

80.9

76.9

84.9

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

100

84

116

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1010--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

960

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

(1030)

Advance angle

deg.

0.8

0.5

1.1

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

0.8

0.5

1.1

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_05

Pump speed

r/min

1600

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

----------

T1=G85

----------

----------

T1=G85

----------

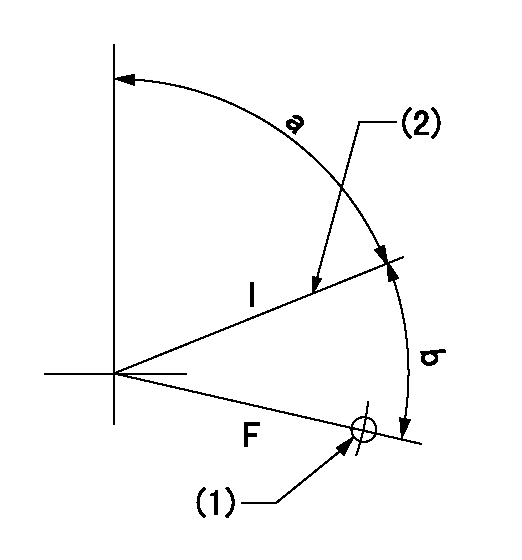

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=32mm

----------

a=70deg+-5deg b=(39deg)+-3deg

----------

aa=32mm

----------

a=70deg+-5deg b=(39deg)+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=12mm

----------

a=29deg+-5deg b=10deg+-5deg

----------

aa=12mm

----------

a=29deg+-5deg b=10deg+-5deg

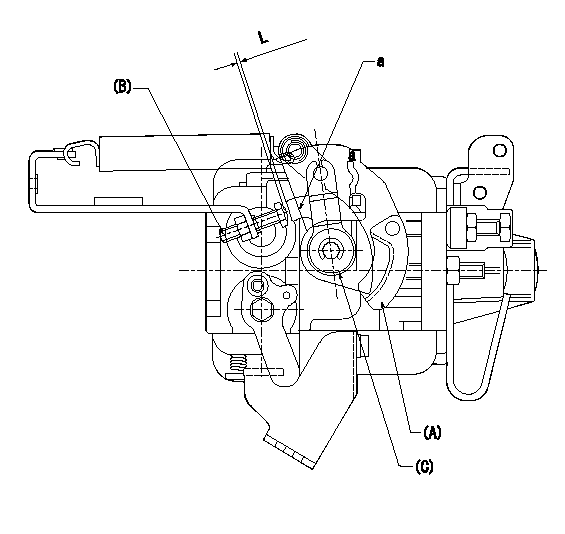

0000001501 LEVER

(A) Speed lever (lower)

(B) Stopper bolt

(C) Special lever (upper)

a:Point A (inside lever)

1. Special lever adjustment

(1)With the speed lever at the idle position, set the accelerator lever stopper bolt so that the accelerator lever contacts the speed lever at point a.

(2)Back off the stopper bolt L and set.

----------

L=1+0.5mm

----------

----------

L=1+0.5mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole (position of gear mark 'S') at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=11deg

----------

a=(60deg)

----------

aa=11deg

----------

a=(60deg)

Information:

Do not bend or add stress the shaft when the nut is loosened or tightened.

d. Loosen the nut on the shaft.e. Tighten nut to ... 3.5 N m (30 lb in)f. Tighten the nut an additional ... 120°g. Remove the nut from the shaft.h. Use 6V1541 Quick Cure Primer on the threads of the shaft and nut.i. Put 9S3265 Retaining Compound on the threads of the shaft and nut.j. Again tighten the nut to ... 3.5 N m (30 lb in)k. Again tighten the nut and additional ... 120°(2) Torque for the bolts that hold back plate ... 10 1 N m (90 10 lb in)(3) Torque for the clamp bolts ... 14 1 N m (120 10 lb in)(4) Bore in the bearings ... 15.921 to 15.931 mm (.6268 to .6272 in) Diameter of the surface on the shaft for the bearings ... 15.875 to 15.885 mm (.6250 to .6254 in)(5) Bore in the housing ... 24.961 to 24.973 mm (.9827 to .9832 in) Outside diameter of the bearing ... 24.846 to 24.859 mm (.9782 to .9787 in)(6) Clearance between the ends of the oil seal ring ... 0.20 to 0.38 mm (.008 to .015 in)(7) End play for the shaft ... 0.08 to 0.25 mm (.003 to .010 in)(8) Put 5P3931 Anti-Seize Compound on the threads and tighten the bolts that hold the turbocharger to the manifold to a torque of ... 54 5 N m (40 4 lb ft)Turbocharger S4A

(1) End play for shaft (new) ... 0.114 0.038 mm (.0045 .0015 in) Maximum permissible end play (worn) ... 0.20 mm (.008 in)(2) Thickness of thrust bearing (where thrust rings contact bearing) ... 5.36 0.03 mm (.211 .001 in)(3) Tighten both band clamps with procedure that follows: a. Tighten to ... 14 1.1 N m (125 10 lb in)b. Tap (hit) clamp lightly all around.c. Tighten again to ... 14 1.1 N m (125 10 lb in)

Do not overtighten the clamps.

(4) Diameter of shaft (new) ... 15.997 to 16.005 mm (.6298 to .6301 in) Bore in the bearing (new) ... 16.035 to 16.043 mm (.6313 to .6316 in)Maximum permissible clearance between bearing and shaft (worn) ... 0.05 mm (.002 in)(5) Maximum permissible gap of oil seal ring, measured in bore of housing ... 0.25 mm (.010 in)(6) Install the compressor wheel (at room temperature) as follows: a. See Compressor Wheel Clearance for the correct shim thickness to use.b. Put compressor wheel on the shaft.c. Put a small amount of clean engine oil on the threads.d. Tighten the nut to a