Information injection-pump assembly

ZEXEL

101491-9810

1014919810

Rating:

Service parts 101491-9810 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

SL70 13 H50A

12.

Open Pre:MPa(Kqf/cm2)

16.7{170}

15.

NOZZLE SET

Cross reference number

ZEXEL

101491-9810

1014919810

Zexel num

Bosch num

Firm num

Name

101491-9810

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

10.9

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

49.4

48.9

49.9

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

9.6+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

9

7

11

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.9)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

49.4

48.9

49.9

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(10.9)

Pump speed

r/min

1700

1700

1700

Average injection quantity

mm3/st.

55.2

51.2

59.2

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1+0.33

Pump speed

r/min

625

625

625

Average injection quantity

mm3/st.

39.8

35.8

43.8

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

91

81

96

Fixing the lever

*

Rack limit

*

Injection quantity adjustment_07

Adjusting point

H

Rack position

9.3+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

7

6.5

7.5

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1330+-25

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1700

Advance angle

deg.

3.5

3.2

3.8

Remarks

Finish

Finish

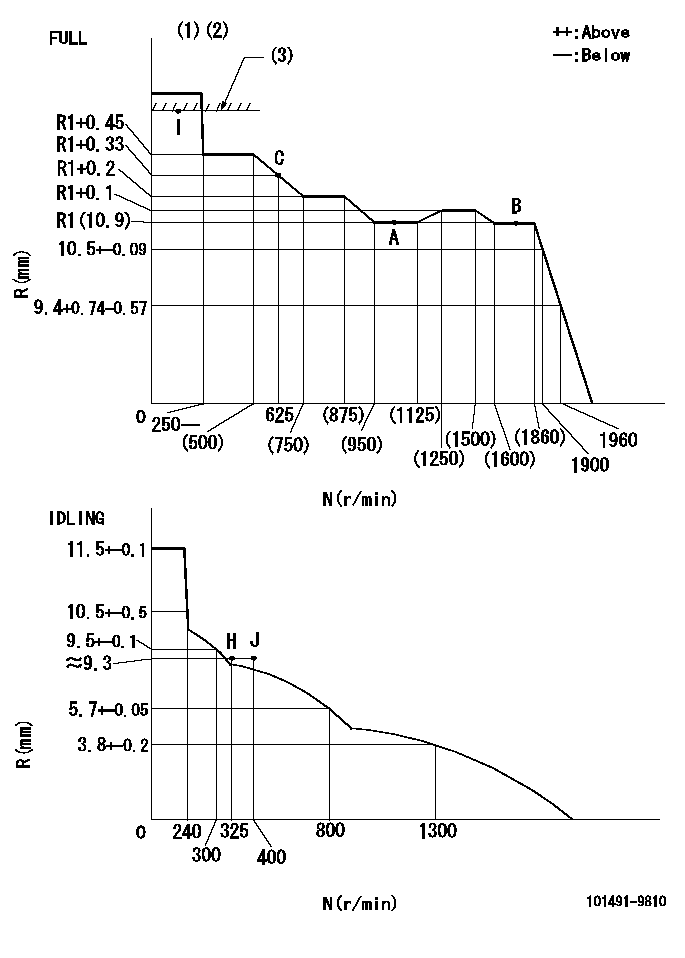

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=G05

----------

----------

T1=G05

----------

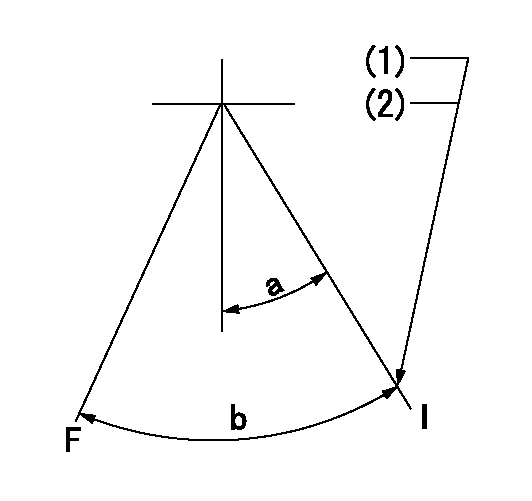

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

(2)Rack position = aa, speed = bb

----------

aa=(9.3)mm bb=325r/min

----------

a=20deg+-5deg b=(41deg)+-3deg

----------

aa=(9.3)mm bb=325r/min

----------

a=20deg+-5deg b=(41deg)+-3deg

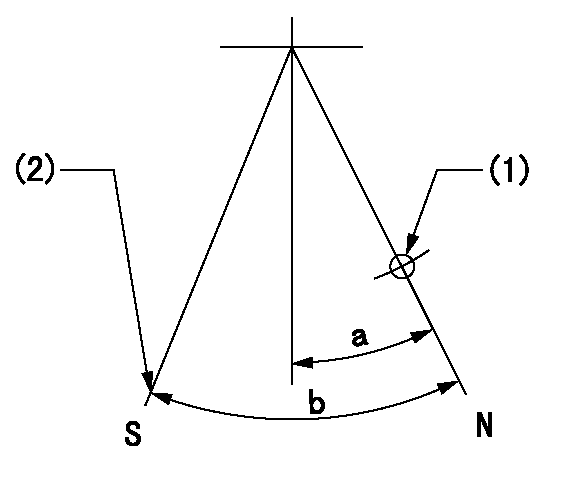

Stop lever angle

N:Pump normal

S:Engine stop

(1)Use the hole at R = aa

(2)Set the stop adjuster screw

----------

aa=39mm

----------

a=14deg+-5deg b=(30deg)+-5deg

----------

aa=39mm

----------

a=14deg+-5deg b=(30deg)+-5deg

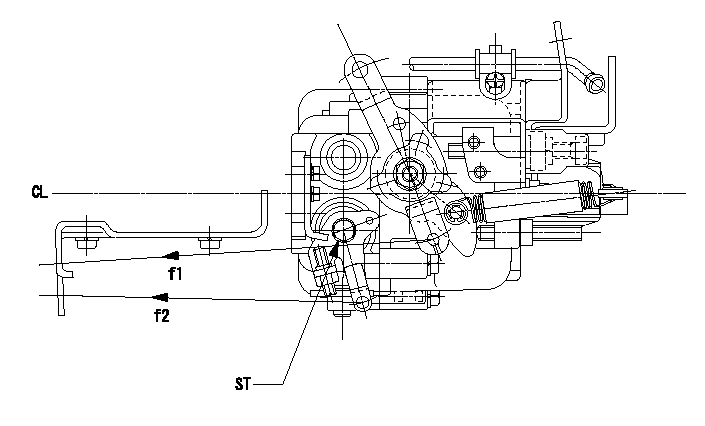

0000001501 LEVER

CL:Center line of camshaft

ST:Stop adjuster screw

f1:Direction for pulling the speed lever

f2:Direction for pulling the stop lever

1. Stop lever adjustment outline

(1)After completing all adjustments, confirm that the lever angle is within the specifications in the normal position.

(2)Set the speed lever in the full speed position.

(3)At pump speed Na, position the rack at non-injection position Ra.

(4)Set the stop adjusting screw to fix the speed lever in the idling position.

(5)Confirm that there is no injection at pump speed Nb.

----------

Na=1860r/min Nb=325r/min Ra=4.6+-0.3mm

----------

----------

Na=1860r/min Nb=325r/min Ra=4.6+-0.3mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=13deg

----------

a=(130deg)

----------

aa=13deg

----------

a=(130deg)

Information:

Heavy Duty Air Cleaners

Generator set engines equipped with heavy duty air cleaners have a serviceable air cleaner element. The element may be cleaned up to six times, but must be replaced Every Year.Remove and Install Air Cleaner Elements

Heavy duty air cleaner:(1) service indicator(2) upper body (air filter element housing)(3) clamps(4) lower body (tube element)(5) dust collector cup1. Loosen clamps (3) between the lower body (4) and the dust collector cup (5). Remove the cup.2. Loosen the clamps between the lower body and the upper body (2). Remove the tube element.3. Clean the tubes from both sides with water or air.4. Remove the air filter element from the upper body (2). Wipe the inside of the upper body clean.5. Inspect and clean air filter element. Install a clean or new element.6. Inspect the gasket between the upper body and lower body. Inspect the seal between the lower body and the dust collector cup. Install a new gasket and seal if necessary.7. Install the cleaned, dry tube element. Tighten the retaining clamps attaching the lower body to the upper body.8. Wipe the dust collector cup clean. Install the cup and tighten the retaining clamps.9. Reset the service indicator (1).Cleaning Air Filter Elements

The primary element (Caterpillar air filters) can be cleaned several times before replacement. The element, when cleaned, should be thoroughly checked for rips or tears in the filter material.Replace the primary element at least EVERY YEAR regardless of operating hours it has accumulated.

Do not clean filter elements by bumping or tapping.Do not use filter elements with damaged pleats, gaskets or seals. Engine damage could result.

Filter elements can be cleaned with air pressure, 205 kPa (30 psi) maximum, or water pressure, 280 kPa (40 psi) maximum, or detergent washing. Have spare elements on hand to use while cleaning used elements.* Direct air or water along the length of the plate inside and outside of air filter element.The element can be washed in warm water and nonsudsing household detergent, such as automatic dishwasher detergent. Rinse inside and outside the pleats. The filter should then be thoroughly air dried and inspected.* Inspect the filter elements after cleaning for any rips, tears or damage. Insert a light inside of the clean, dry element. Do not use a filter element with damaged pleats, gaskets or seals. Discard the element if damaged.* Wrap and store the clean filter elements in a clean, dry place.* Reset the service indicator by pushing the piston plunger in.For more information on air cleaner element cleaning, refer to Guideline for Reusable Parts-Cleaning and Inspection of Air Filters, SEBU8062.Air Starter & Air Tank (If Equipped)

Check Lubricator Level

Never allow the lubricator bowl (if equipped) to become empty. The starting motor will be damaged by lack of proper lubrication.

The vanes of the starting motor are lubricated with a fine mist of oil from the motor lubricator. Check the level of oil in the lubricator bowl. If the bowl is less than half full, add lubricant. Use non detergent 10W engine oil for temperatures

Generator set engines equipped with heavy duty air cleaners have a serviceable air cleaner element. The element may be cleaned up to six times, but must be replaced Every Year.Remove and Install Air Cleaner Elements

Heavy duty air cleaner:(1) service indicator(2) upper body (air filter element housing)(3) clamps(4) lower body (tube element)(5) dust collector cup1. Loosen clamps (3) between the lower body (4) and the dust collector cup (5). Remove the cup.2. Loosen the clamps between the lower body and the upper body (2). Remove the tube element.3. Clean the tubes from both sides with water or air.4. Remove the air filter element from the upper body (2). Wipe the inside of the upper body clean.5. Inspect and clean air filter element. Install a clean or new element.6. Inspect the gasket between the upper body and lower body. Inspect the seal between the lower body and the dust collector cup. Install a new gasket and seal if necessary.7. Install the cleaned, dry tube element. Tighten the retaining clamps attaching the lower body to the upper body.8. Wipe the dust collector cup clean. Install the cup and tighten the retaining clamps.9. Reset the service indicator (1).Cleaning Air Filter Elements

The primary element (Caterpillar air filters) can be cleaned several times before replacement. The element, when cleaned, should be thoroughly checked for rips or tears in the filter material.Replace the primary element at least EVERY YEAR regardless of operating hours it has accumulated.

Do not clean filter elements by bumping or tapping.Do not use filter elements with damaged pleats, gaskets or seals. Engine damage could result.

Filter elements can be cleaned with air pressure, 205 kPa (30 psi) maximum, or water pressure, 280 kPa (40 psi) maximum, or detergent washing. Have spare elements on hand to use while cleaning used elements.* Direct air or water along the length of the plate inside and outside of air filter element.The element can be washed in warm water and nonsudsing household detergent, such as automatic dishwasher detergent. Rinse inside and outside the pleats. The filter should then be thoroughly air dried and inspected.* Inspect the filter elements after cleaning for any rips, tears or damage. Insert a light inside of the clean, dry element. Do not use a filter element with damaged pleats, gaskets or seals. Discard the element if damaged.* Wrap and store the clean filter elements in a clean, dry place.* Reset the service indicator by pushing the piston plunger in.For more information on air cleaner element cleaning, refer to Guideline for Reusable Parts-Cleaning and Inspection of Air Filters, SEBU8062.Air Starter & Air Tank (If Equipped)

Check Lubricator Level

Never allow the lubricator bowl (if equipped) to become empty. The starting motor will be damaged by lack of proper lubrication.

The vanes of the starting motor are lubricated with a fine mist of oil from the motor lubricator. Check the level of oil in the lubricator bowl. If the bowl is less than half full, add lubricant. Use non detergent 10W engine oil for temperatures

Have questions with 101491-9810?

Group cross 101491-9810 ZEXEL

Nissan-Diesel

101491-9810

INJECTION-PUMP ASSEMBLY